Fluorinated hydrogenation catalyst with silicon oxide-alumina as carrier and its production

A technology of silica and alumina, applied in physical/chemical process catalysts, aromatics hydrogenation refining, chemical instruments and methods, etc., can solve the problems of low activity and limited improvement, and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

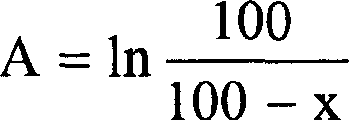

Method used

Image

Examples

example 1

[0027] Take by weighing 2000 grams of aluminum hydroxide powder (dried rubber powder produced by Changling Refining and Chemical Company Catalyst Factory, 70% by weight on a dry basis) and 631 grams of silica sol (Qingdao Ocean Chemical Plant product) containing 25% of silicon dioxide, after mixing Extrude into a butterfly bar with a circumscribed circle diameter of 1.3 mm using an extruder, dry the wet bar at 120° C. for 4 hours, and bake it at 600° C. for 3 hours to obtain carrier S1. The silicon oxide content in the carrier S1 is 10.1% by weight.

[0028]Weigh 200 grams of carrier S1, impregnate the carrier with 176 ml of aqueous solution containing 16.9 grams of ammonium fluoride (analytical grade, product of Beijing Chemical Plant) for 2 hours, dry at 120°C for 3 hours, and roast at 480°C for 3 hours to obtain fluorine-containing Silica-alumina support. With 170 milliliters of the aqueous solution containing ammonium paramolybdate (chemically pure, Beijing Chemical Plant ...

example 2

[0030] Weigh 200 g of carrier S1, impregnate the carrier with 176 ml of an aqueous solution containing 19.1 g of ammonium fluoride for 2 hours, dry at 120° C. for 3 hours, and calcinate at 420° C. for 3 hours to obtain a fluorine-containing silica-alumina carrier. Impregnate the above-mentioned carrier with 170 ml of an aqueous solution containing 24.7 grams of ammonium paramolybdate for 3 hours, dry at 280°C for 8 hours, then impregnate with 160 ml of an aqueous solution containing 24.6 grams of nickel nitrate and 66.7 grams of ammonium metatungstate for 3 hours, and wet the strip at 120 ℃ drying for 4 hours and 500 ℃ calcining for 4 hours to obtain catalyst C2. The composition of catalyst C2 after calcination is listed in Table 1.

example 3

[0032] Weigh 200 g of carrier S1, impregnate the carrier with 176 ml of an aqueous solution containing 8.9 g of ammonium fluoride for 2 hours, dry at 120° C. for 3 hours, and calcinate at 420° C. for 3 hours to obtain a fluorine-containing silica-alumina carrier. Impregnate the above-mentioned carrier with 170 ml of an aqueous solution containing 17.5 grams of ammonium paramolybdate for 3 hours, dry at 280°C for 8 hours, then impregnate with 162 ml of an aqueous solution containing 44.3 grams of nickel nitrate and 74.4 grams of ammonium metatungstate for 3 hours, and wet the strip at 120 ℃ drying for 4 hours, followed by calcination at 500 ℃ for 4 hours to obtain catalyst C3. The composition of catalyst C3 after calcination is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com