Modified molecular screen base precious metal diesel oil deepness hydrogenation dearomatization catalyst and method of preparing the same

A deep hydrogenation, molecular sieve-based technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, hydrogenation and refining of aromatics, etc., can solve the problem of secondary cracking reaction products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical characteristics of the present invention will be described in detail below in conjunction with specific embodiments.

[0018] (1) The preparation process of the catalyst

[0019] 100 grams of HY molecular sieves obtained by ion exchange were placed in 500 mL of 0.2 mol / L NH 4 In the F aqueous solution, stir at room temperature for 1 hour, filter, dry at 120°C, and impregnate the sample calcined at 450°C in an equal volume of 5% SiO 2 in a silica sol solution, dried at 120°C, and then calcined in a muffle furnace at a temperature programmed to 750°C for 4 hours to obtain a modified molecular sieve.

[0020] Impregnate active components and auxiliary components by step-by-step impregnation, let stand for 24 hours, dry naturally, dry at 120°C, and roast at 400°C to obtain Pt-Pd-Cr / HY-γ-Al 2 o 3 catalyst. Wherein the total content of precious metals is 1.0%, Pd / Pt is 4 / 1, and Cr is a co-catalyst with a content of 0.6%.

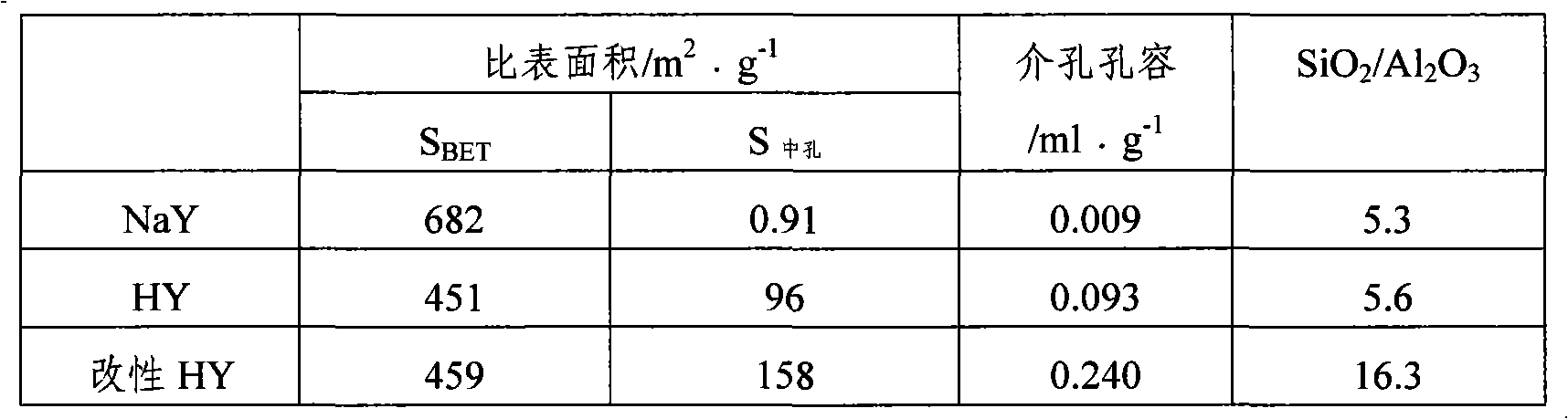

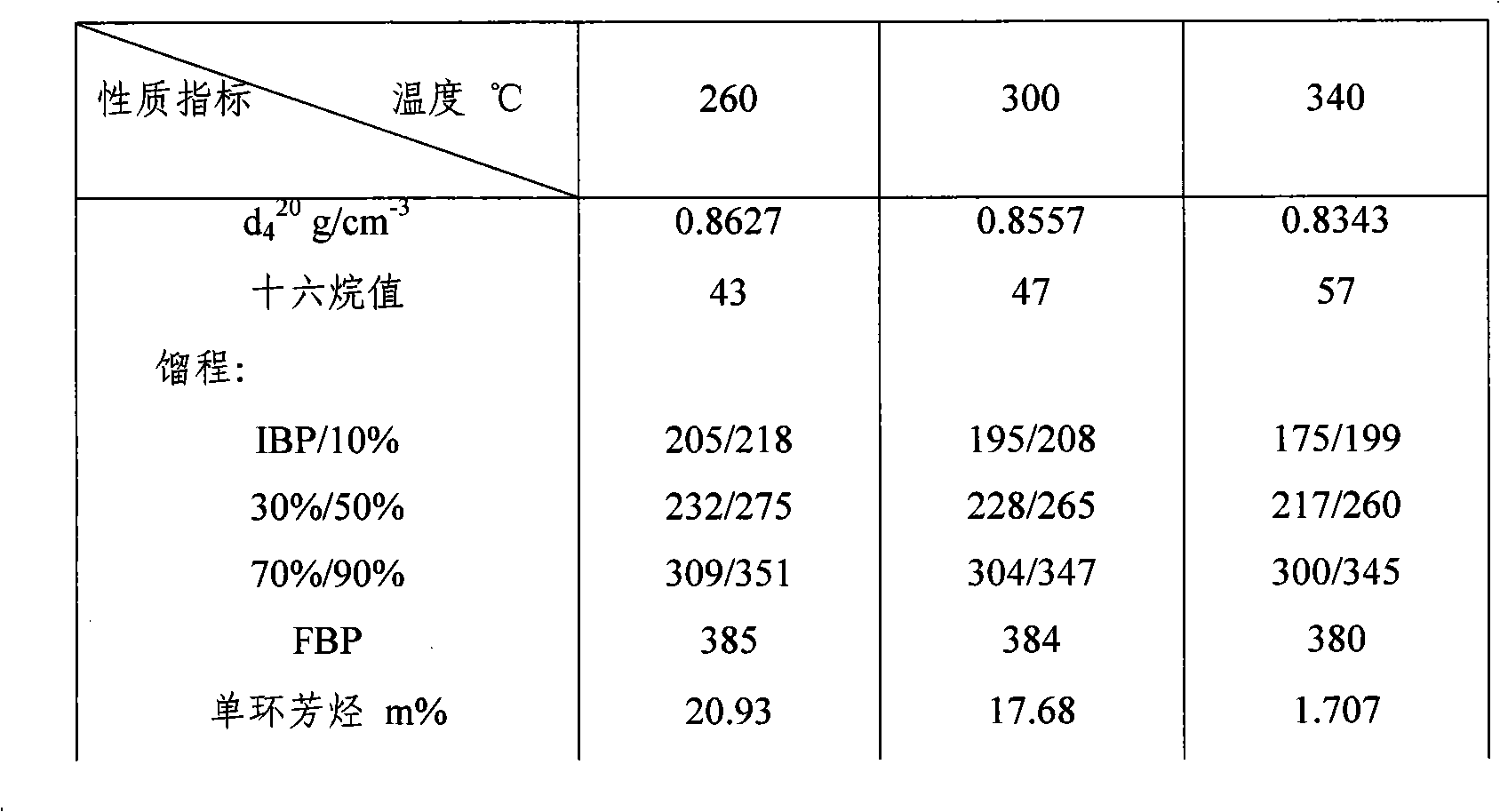

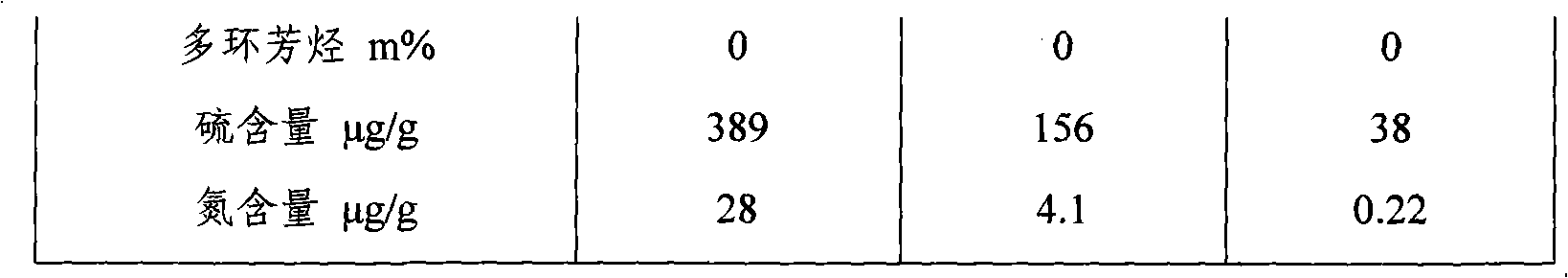

[0021] (2) Pore structure paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com