Aromatics hydrogenation catalyst and preparation method and application of aromatics hydrogenation catalyst

A technology for the hydrogenation of aromatics and catalysts, which is applied in the fields of hydrogenation and refining of aromatics, molecular sieve catalysts, chemical instruments and methods, etc., and can solve problems such as low stability and catalytic activity and limited catalytic applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mesoporous zeolite with conventional molecular sieve and mesoporous material characteristics obtained by prior art (known post-processing method, soft template method or hard template method), this embodiment takes Na-type mesoporous ZSM-5 zeolite as an example Instructions, according to the liquid-solid ratio of mesoporous zeolite and ammonium nitrate water-soluble 1:10, add Na-type mesoporous ZSM-5 zeolite to 0.1mol / L ammonium nitrate solution, stir at 90°C for 90 minutes under reflux, and filter , washed, dried at 120°C for 6 hours, baked at 500°C for 4 hours, and repeated three times. Obtain H-type mesoporous ZSM-5, take gained powder 5g and add 5mL containing Pt mass fraction and be 0.5% chloroplatinic acid aqueous solution (also can be the salt solution of palladium, rhodium, silver, ruthenium, gold, osmium, iridium or Mixed solution), let stand and soak for 4 hours, dry at 120°C for 4 hours, and bake at 500°C for 4 hours. The calcined material was pressed into t...

Embodiment 2

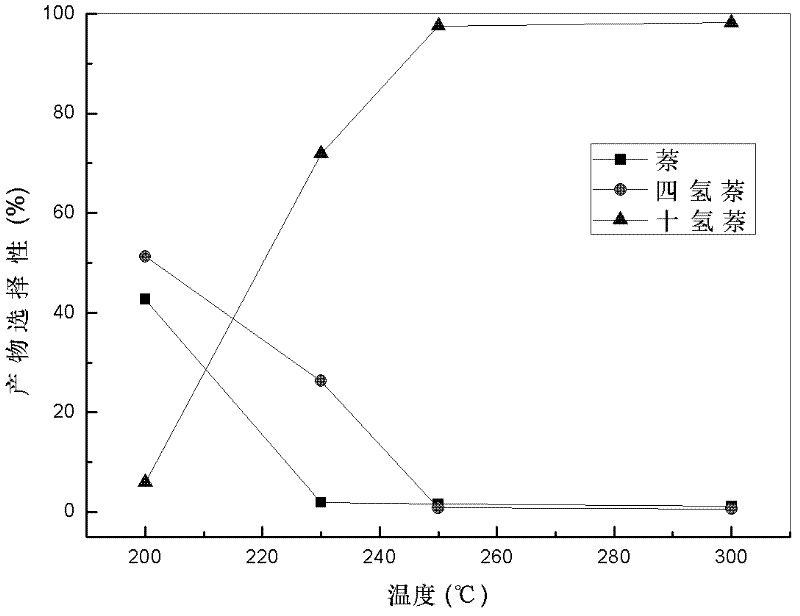

[0026] The catalytic hydrogenation reaction activity evaluation experiment adopts the fixed-bed micro-hydrogenation reactor-gas chromatography device as the activity evaluation device. The reaction raw material is a tridecane solution with a mass content of 10% naphthalene. First, 3ml of Pt / mesoporous ZSM-5 catalyst was reduced at 450°C for 3 hours under hydrogen atmosphere and normal pressure, and then the temperature was lowered to 300°C to feed the reaction raw materials for hydrogenation reaction. The reaction conditions are pressure 4MPa, raw oil volume space velocity 1h -1 . Hydrogen oil volume ratio 600Nm 3 / m 3 , sampled after 5 hours of reaction. Naphthalene hydrogenation activity evaluation results are shown in Table 2 and figure 1 .

Embodiment 3

[0028] Except that the evaluation reaction temperature is different at 250°C, all the other are the same as Example 2, and the evaluation results are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com