Rare earth-containing diesel fuel distillate oil hydrogenation catalyst, preparation and application thereof

A technology for hydrogenation catalyst and distillate oil, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as diesel yield decline and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

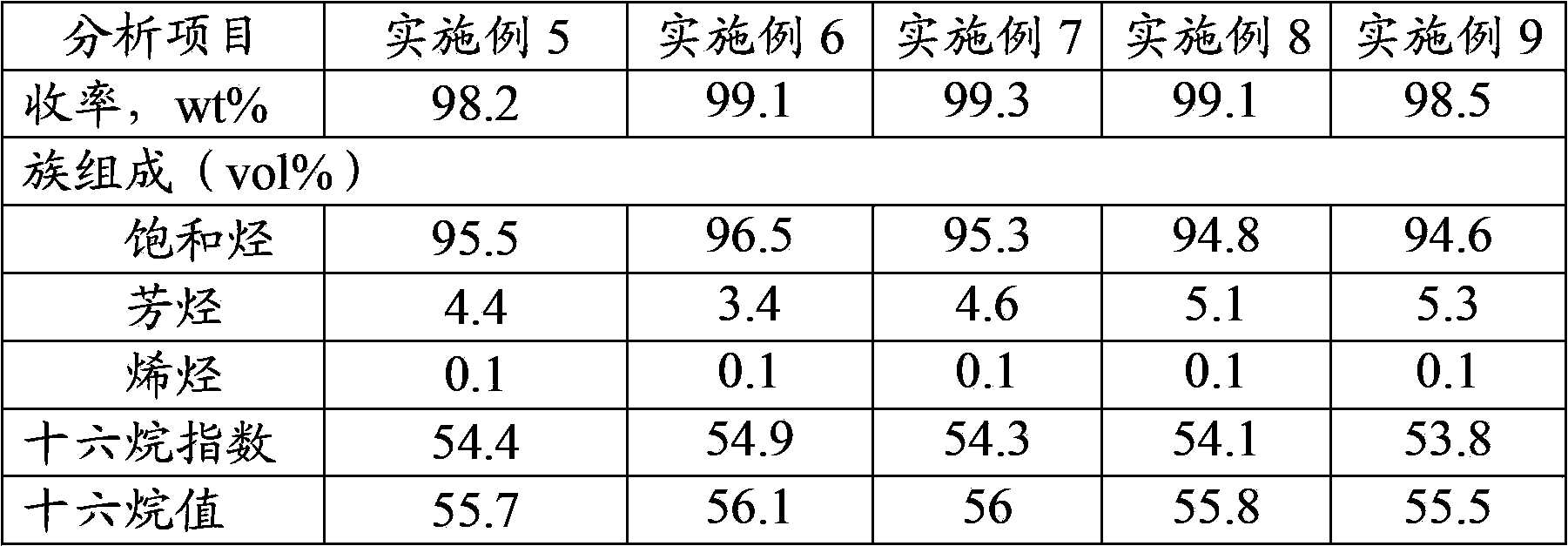

Examples

Embodiment 1

[0037] Weigh 145g water glass (SiO 2 , 15.5wt%) was slowly added to 360g of 10wt% dilute nitric acid solution, stirred, and set aside. Weigh 79g of crystalline aluminum chloride and add it into 160g of deionized water, stir until dissolved, and set aside. Then slowly introduce the prepared water glass solution into AlCl 3 800g of deionized water was added to a 2000mL plastic beaker, and 8wt% ammonia solution and the above-mentioned silicon-aluminum mixed solution were added to the plastic beaker in parallel, and the pH of the solution was controlled during the process. 10.0±0.5. After the titration, the material was aged at 70°C for 48h. After aging, separation, washing, ammonium exchange, drying, and crushing are carried out to obtain amorphous silica-alumina powder for use.

Embodiment 2

[0039] Add 170g of SB powder to 1500g of 5wt% nitric acid solution, stir evenly, raise the temperature to 60°C, react for 3h, neutralize with 10wt% ammonia water, control the end point pH value at 8.5±0.2, and age for 48h. After aging, separate, wash, dry and pulverize to obtain macroporous alumina powder.

Embodiment 3

[0041] Add 6000mL deionized water to 1000g H-USY zeolite for beating, heat up to 95°C, then add 600mL chlorinated mixed rare earth solution (containing 27.2g Re 2 o 3 ), reacted for 120 minutes, filtered, washed with water, and the filter cake was dried at 110°C overnight and then roasted at 580°C for 5h to obtain the rare earth USY zeolite A.

[0042] Take 140g of the rare earth USY zeolite A prepared above, 100g of amorphous silica-alumina, 80g of macroporous alumina powder, and 30g of Tianqing powder and mix them evenly. Measure 280g of 8wt% nitric acid solution and add the above mixed powder, after fully mixing, extrude clover-shaped strips on the extruder, then dry at 110°C overnight and then roast at 550°C for 5h to obtain the shaped catalyst carrier Z1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com