Preparation method of hydrogenation catalyst

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems affecting the uniform distribution of active metals, large loss of catalyst specific surface area, and reduced activity and selectivity. Achieve the effect of saving time and energy, facilitating the play of metal activity, improving acidity and acid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

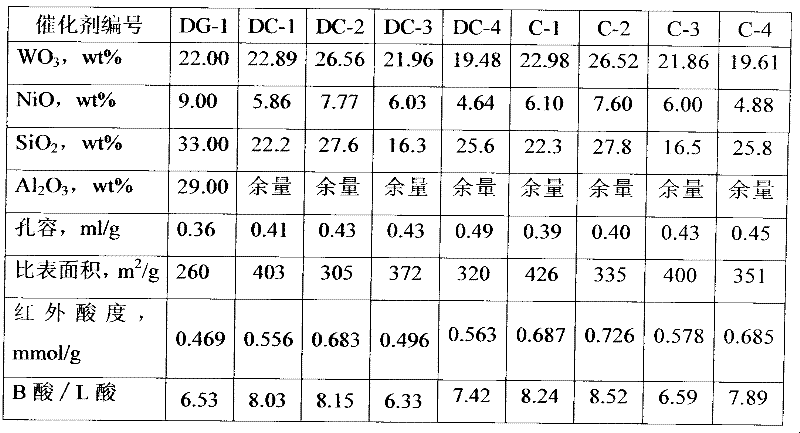

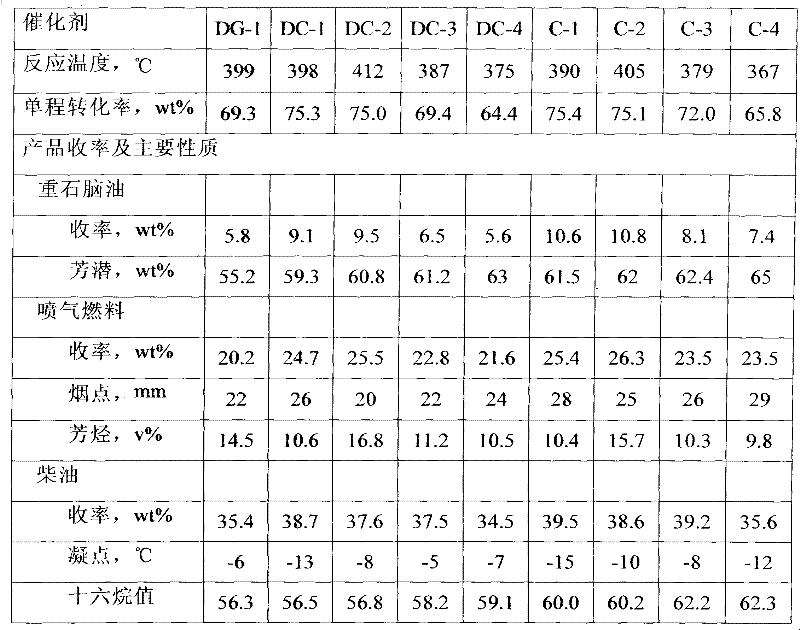

Embodiment 1

[0050] The step of roasting at 550° C. for 4 hours in Comparative Example 2 was canceled, and the extruded strip drying condition was changed to be dried at 180° C. for 4 hours. The rest are the same to obtain catalyst C-1.

Embodiment 2

[0055] The step of roasting at 550° C. for 4 hours in Comparative Example 3 was canceled, and the extruded strip drying condition was changed to be dried at 220° C. for 5 hours. The rest are the same to obtain catalyst C-2.

Embodiment 3

[0060] The step of roasting at 550° C. for 4 hours in Comparative Example 4 was canceled, and the extruded strip drying condition was changed to be dried at 160° C. for 6 hours. The rest are the same to obtain catalyst C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com