Method for preparing hydrocracking catalyst

A hydrocracking and catalyst technology, which is applied in the field of CNPC hydrocracking catalyst and its preparation, can solve the problems of low catalyst activity, catalyst loss, large surface area, etc., and achieve the benefit of metal activity and cracking activity increase , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

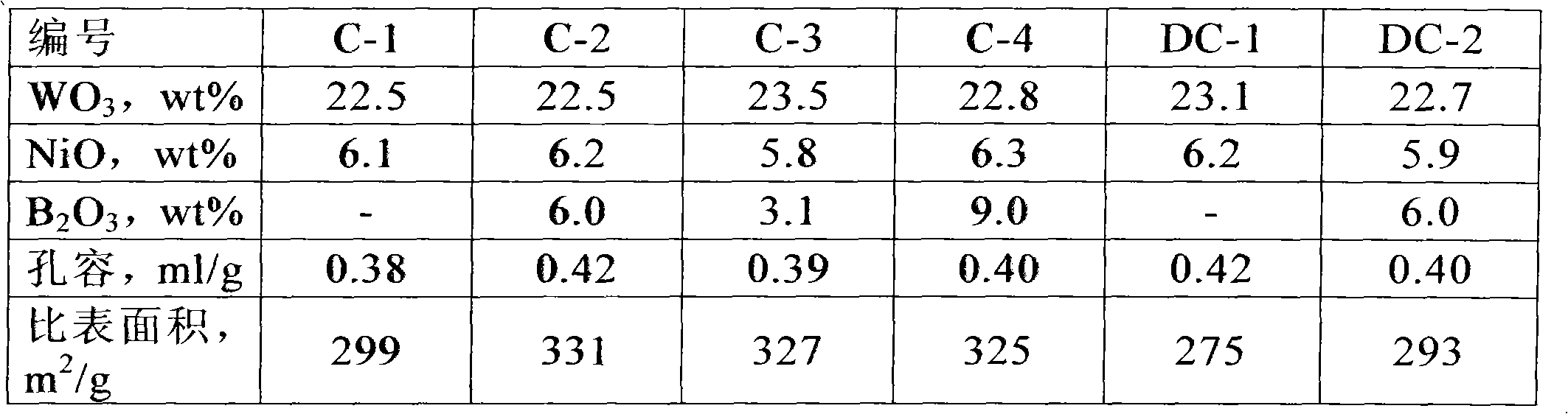

Embodiment 1

[0029] Put 150.7 grams of amorphous silica-alumina prepared by graft copolymerization, 55.6 grams of macroporous alumina, and 148.4 grams of binder prepared by dilute nitric acid and small-pored alumina into a roller compactor, and then rolled for 30 minutes, and then added Appropriate amount of water, grind until the paste can be extruded, extruded, and dried at 180°C for 4 hours to obtain the carrier. with WO 3 56g / 100ml, NiO12g / 100ml impregnation solution impregnated the carrier at room temperature for 2 hours, separated the mother liquor, dried at 110°C for 4 hours, and calcined at 500°C for 4 hours to obtain catalyst C1.

Embodiment 2

[0034] Put 133.4 grams of amorphous silica-alumina prepared by 150.7 grams of graft copolymerization, 28.5 grams of boric acid, 46.6 grams of macroporous alumina, and 133.4 grams of adhesives prepared by dilute nitric acid and small-pored alumina into a rolling machine, and roll for 30 Minutes, then add an appropriate amount of water, grind until the paste can be extruded, extrude, and dry the extruded strips at 150 ° C for 8 hours to obtain a carrier. with WO 3 56g / 100ml, NiO12g / 100ml impregnation solution impregnated the carrier at room temperature for 2 hours, separated the mother liquor, dried at 110°C for 4 hours, and calcined at 500°C for 4 hours to obtain catalyst C2.

Embodiment 3

[0036] Put 133.4 grams of amorphous silica-alumina prepared by 150.7 grams of graft copolymerization, 14.3 grams of boric acid, 46.6 grams of macroporous alumina, and 133.4 grams of adhesives prepared by dilute nitric acid and small-pored alumina into a rolling machine, and roll for 30 Minutes, then add an appropriate amount of water, grind until the paste can be extruded, extrude, and dry the extruded strips at 200 ° C for 6 hours to obtain a carrier. with WO 3 56g / 100ml, NiO12g / 100ml impregnation solution impregnated the carrier at room temperature for 2 hours, separated the mother liquor, dried at 110°C for 4 hours, and calcined at 500°C for 4 hours to obtain catalyst C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com