Preparation and application of a manganese oxide-supported molecular sieve catalyst

A technology of manganese oxide and molecular sieve, which is applied in the field of catalysis, can solve problems such as the influence of molecular sieve surface properties, unfavorable pore wall modification and treatment, etc., and achieve the effects of convenient and fast energy, high catalytic activity and stability, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

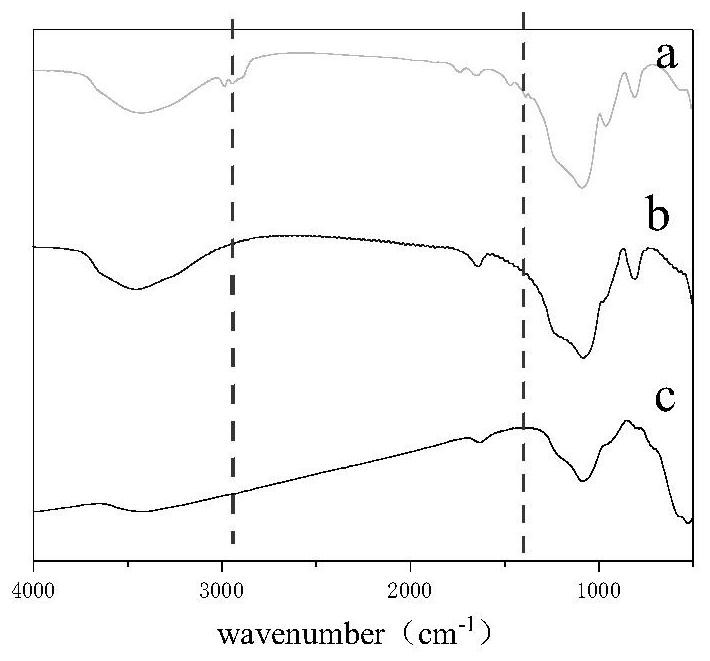

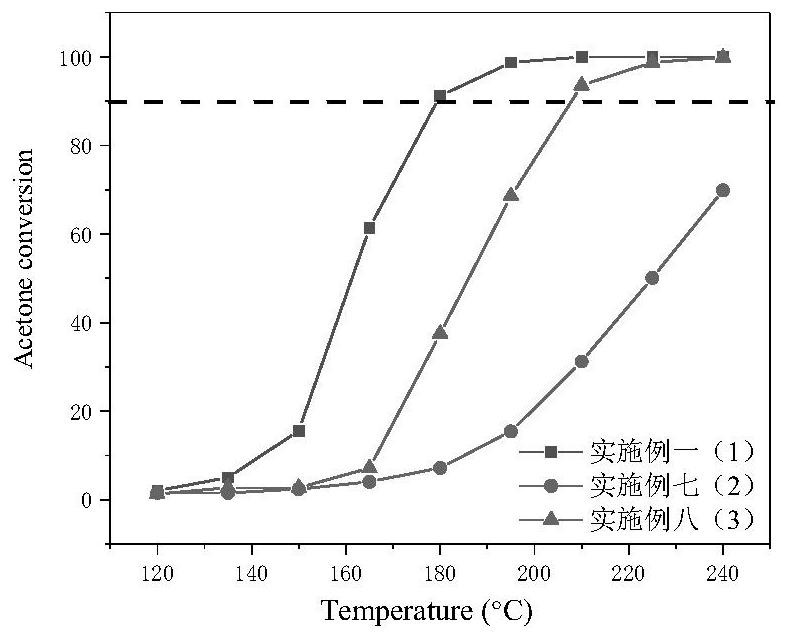

[0030] In this example, using triblock copolymer P123 as template agent and ethyl orthosilicate (TEOS) as silicon source, pure silicon SBA-15 mesoporous molecular sieve was synthesized under acidic conditions.

[0031] The specific synthesis steps are as follows: weigh 2g of P123, mix with 60ml of 2mol / L hydrochloric acid and 15ml of distilled water, stir in a 40°C water bath for 2h to dissolve it, then add 4.17ml of ethyl orthosilicate, continue to stir for 24h, add In a stainless steel reactor with a polytetrafluoroethylene lining, stand for 24 hours in an oven at 100 ° C, take out and cool, wash with distilled water and suction filtration, and dry to obtain SBA-15 carrier without removing template P123 .

[0032] Weigh 3.5g of potassium permanganate and 1.2g of sba-15 carrier without removing template P123 and dissolve it in 60ml of 1mol / L nitric acid solution, stir magnetically for 1h to make the mixture uniform, and then transfer the uniformly mixed solution to a polytetr...

Embodiment 2

[0034] Weigh 3.5g of potassium permanganate and 0.8g of sba-15 carrier without removing template P123 and dissolve it in 60ml of 1mol / L nitric acid solution, stir magnetically for 1h to make the mixing uniform, and then transfer the mixed uniform solution to a polytetrafluoroethylene In a stainless steel reactor lined with ethylene, the reactor was placed in an oven at 100 °C for 12 h. The obtained solution was suction filtered and washed with deionized water for several times to remove impurities, then placed in an oven for drying at 100 °C for 12 hours, and finally calcined at 400 °C for 2 hours to obtain the prepared supported catalyst.

Embodiment 3

[0036] Weigh 3.5g of potassium permanganate and 1.2g of sba-15 carrier without removing template P123 and dissolve it in 60ml of 1mol / L nitric acid solution, stir magnetically for 1h to make the mixing uniform, and then transfer the mixed uniform solution to a polytetrafluoroethylene The ethylene-lined stainless steel reaction kettle was placed in an oven at 100 °C for 12 h. The obtained solution was suction filtered and washed with deionized water for several times to remove impurities, then dried in an oven at 100 °C for 12 hours, and finally calcined at 550 °C for 4 hours to obtain the prepared supported catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com