Catalyst for low-temperature catalytic oxidation of formaldehyde and preparation method thereof

A low-temperature catalysis and catalyst technology, applied in the chemical industry, can solve the problems of poor catalysis effect and increase catalyst, and achieve the effects of high catalytic activity and stability, promoting oxidation activity and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

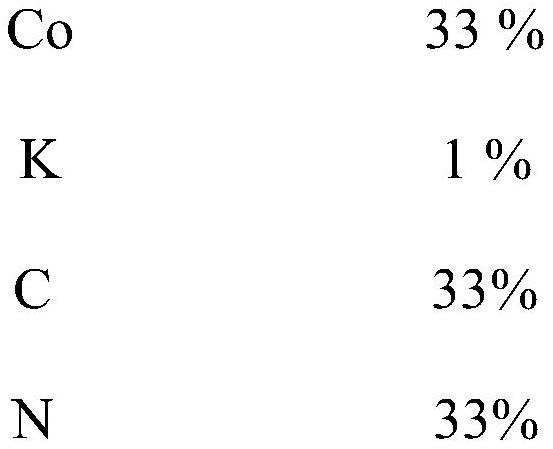

[0023] A catalyst for low-temperature catalytic oxidation of formaldehyde, potassium ion modified cobalt ammonium complex method, that is, the cobalt component is first precipitated on the surface of activated carbon by the deposition precipitation method, and then the potassium ion-containing ammonia solution is used to form a complex with the precipitate, Further drying treatment in the system. Convert the feeding amount of cobalt nitrate, potassium nitrate, activated carbon and ammonia water into cobalt, potassium, carbon and nitrogen atoms respectively, and the contents of each component are as follows:

[0024]

[0025] The preparation method of above-mentioned catalyst specifically comprises the steps:

[0026] 1) Add 140mL of 1mol / L Co(NO 3 ) 2 Add the solution and 170mL of 1mol / L sodium carbonate solution drop by drop to the beaker containing the suspension of 1.7g of activated carbon and 20mL of water, and control the amount of each drop of co-flow to 0.05-0.07ml...

Embodiment 2

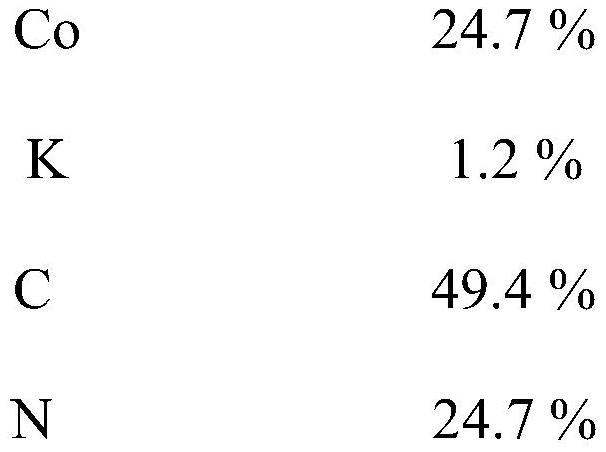

[0029] A catalyst for low-temperature catalytic oxidation of formaldehyde, potassium ion modified cobalt ammonium complex method, that is, the cobalt component is first precipitated on the surface of activated carbon by the deposition precipitation method, and then the potassium ion-containing ammonia solution is used to form a complex with the precipitate, Further drying treatment in the system. Convert the feeding amount of cobalt nitrate, potassium nitrate, activated carbon and ammonia water into cobalt, potassium, carbon and nitrogen atoms respectively, and the contents of each component are as follows:

[0030]

[0031] The preparation method of above-mentioned catalyst specifically comprises the steps:

[0032] 1) Add 120mL of 1mol / L Co(NO 3 ) 2 Add the solution and 145mL of 1mol / L sodium carbonate solution drop by drop to the beaker containing the suspension of 2.9g of activated carbon and 20mL of water, and control the amount of each drop of co-flow to 0.05-0.07ml...

Embodiment 3

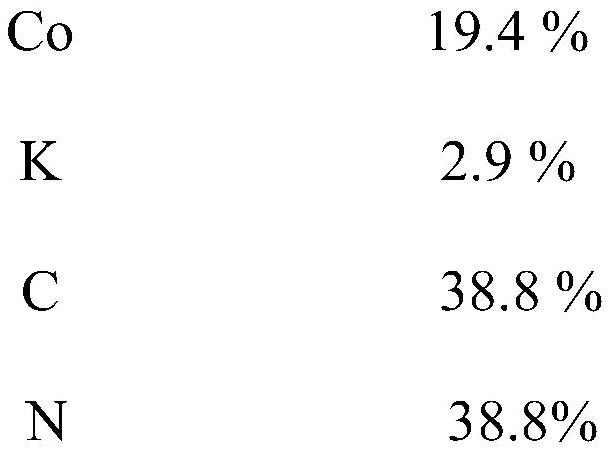

[0035] A catalyst for low-temperature catalytic oxidation of formaldehyde, potassium ion modified cobalt ammonium complex method, that is, the cobalt component is first precipitated on the surface of activated carbon by the deposition precipitation method, and then the potassium ion-containing ammonia solution is used to form a complex with the precipitate, Further drying treatment in the system. Convert the feeding amount of cobalt nitrate, potassium nitrate, activated carbon and ammonia water into cobalt, potassium, carbon and nitrogen atoms respectively, and the contents of each component are as follows:

[0036]

[0037] The preparation method of above-mentioned catalyst specifically comprises the steps:

[0038] 1) Add 120mL of 1mol / L Co(NO 3 ) 2 Add the solution and 145mL of 1mol / L sodium carbonate solution drop by drop to the beaker containing the suspension of 2.9g of activated carbon and 20mL of water, and control the amount of each drop of co-flow to 0.05-0.07ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com