Method for preparing hydrogenation catalyst

A hydrogenation catalyst and hydrogenation activity technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. problems, to achieve the effect of saving time and energy, conducive to the play of metal activity, and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

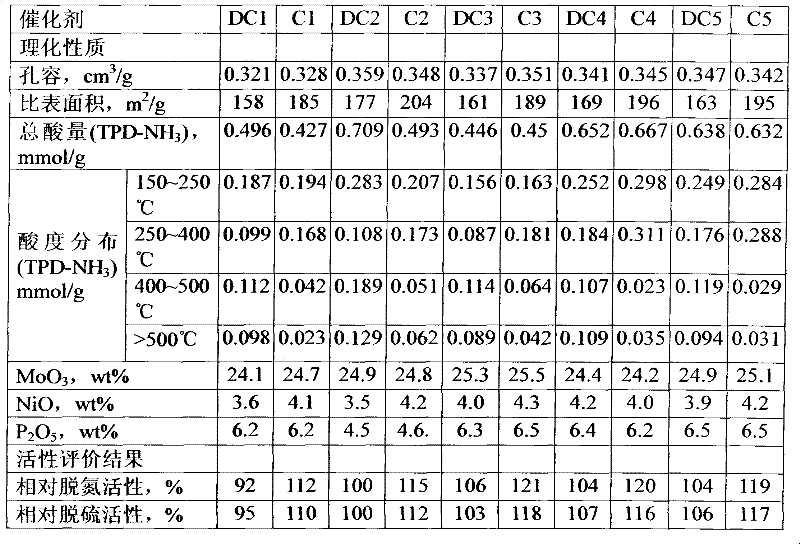

[0019] The preparation method of the hydrogenation catalyst of the present invention, the preparation method of the present invention is specifically described by taking the following catalyst as an example, with silicon oxide and aluminum oxide as the carrier, molybdenum and nickel as the hydrogenation active metal component, and phosphorus as the auxiliary agent, specifically as follows:

[0020] (1) Add macroporous aluminum hydroxide, small pore aluminum hydroxide and extrusion aid to the premixer and mix evenly, then add nano-silicon-containing compound, preferably nano-silicon dioxide, and peptizer aqueous solution to knead to form a plastic body, and shape it;

[0021] (2) drying the molded product obtained in step (1) at 100-280°C for 4-24 hours, preferably at 150-250°C for 4-24 hours;

[0022] (3) Prepare a molybdenum-nickel-phosphorus impregnation solution, then use the impregnation solution to impregnate the dried product obtained in step (2), then dry it at 90-150°C ...

Embodiment 1

[0030] In Comparative Example 1, the step of roasting the carrier at 550° C. for 4 hours under air flow was canceled, and the clover strips were dried at 110° C. for 4 hours instead of at 180° C. for 4 hours, and the rest were the same. Catalyst C1

Embodiment 2

[0034] In Comparative Example 2, the step of roasting the carrier at 600°C for 4 hours under air flow was canceled, the clover strips were dried at 120°C for 4 hours, and dried at 230°C for 5 hours, and the rest were the same. Catalyst C2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com