Method for preparing selective hydrogenation ring-opening catalyst for aromatic hydrocarbons with double rings or more

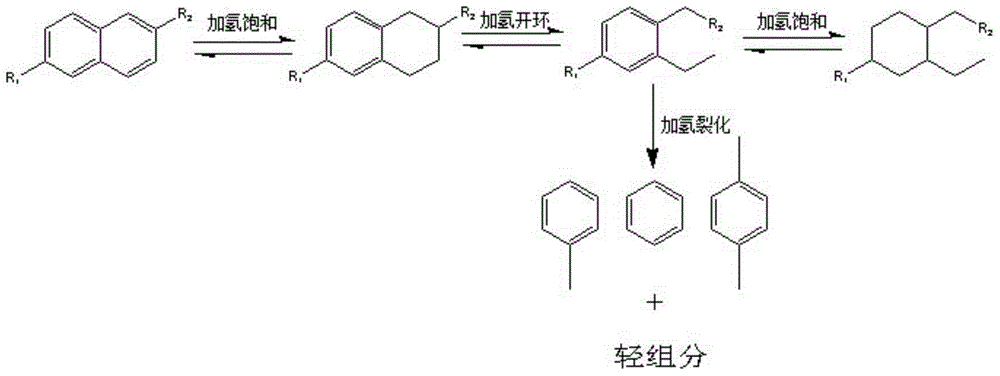

A hydrogenation ring-opening and selective technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Isomerization activity and other issues to achieve the effect of preventing secondary cracking, improving selectivity, and increasing hydrogenation saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

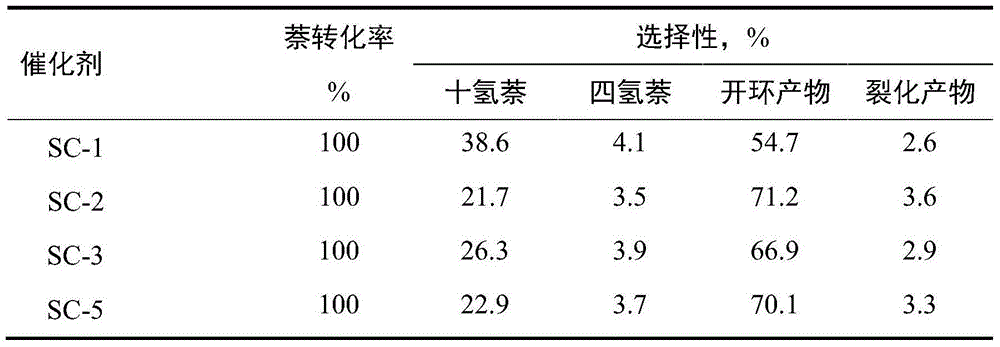

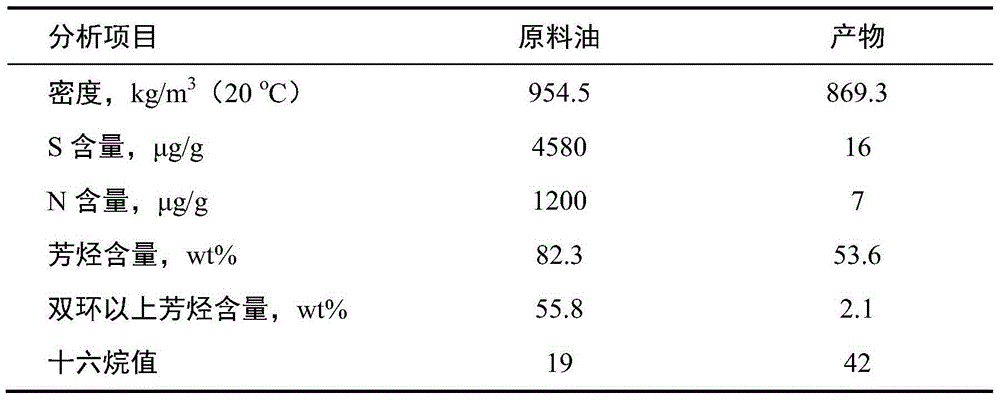

Examples

Embodiment -1

[0033] The synthesis of SAPO-5 / ZSM-5 composite molecular sieve: add 136.0g phosphoric acid (AR, mass concentration 85%) to 432.0g deionized water and mix uniformly, add 93.0g pseudo-boehmite (Shandong Aluminum Co., Ltd., Al 2 o 3 Mass content is 72.0wt%), after uniform mixing reaction certain hour, add 74.0g templating agent triethylamine (abbreviation TEA, Tianjin, purity 99%) and 25.0g acidic silica sol (Qingdao, SiO 2 Content 30wt%), after mixing uniformly to form a sol, 125.0g of 10wt.% hexadecyltrimethoxyorganosilicon ammonium chloride (TPHAC, Shanghai, chemically pure) ethanol solution is added in the above-mentioned sol system, and the sol is transferred to Put the sol into a polytetrafluoroethylene autoclave, and age at 100°C for 4 hours to obtain SAPO-5 seed crystals, then add 80.0g of ZSM-5 zeolite, and crystallize at 180°C After 24 hours. The crystallized product was separated, the obtained solid product was washed with deionized water to pH = 7-8, and dried at 12...

Embodiment -2

[0035] With 47.0g modified Beta molecular sieve (dry basis content 85%), 45.0g SAPO-5 / ZSM-5 composite molecular sieve (dry basis content 90%), 160.0g modified macroporous alumina (dry basis content 75%), Mix 6.0g of scallop powder and 6.0g of methyl cellulose and put it into a kneader for 10 minutes, then add 225.0g of acidic solution prepared by water, nitric acid and citric acid into the dry powder one by one, and knead until it can be extruded. Extruded once each through an empty plate and a cylindrical orifice plate with a diameter of 8 mm, and finally formed into a butterfly-shaped bar with a diameter of 1.6 mm; the obtained wet bar was first cured in an oven at 30°C for 24 hours, and then dried in an oven at 120°C for 8 hours. Finally, it was placed in a muffle furnace and the temperature was programmed to rise to 550° C. for 4 h to obtain the carrier ZT-1.

Embodiment -3

[0037] With 94.0g modified Beta molecular sieve (dry basis content 85%), 45.0g SAPO-5 / ZSM-5 composite molecular sieve (dry basis content 90%), 107.0g modified macroporous alumina (dry basis content 75%), Mix 6.0g of scallop powder and 6.0g of methyl cellulose and put it into a kneader for 10 minutes, then add 225.0g of acidic solution prepared by water, nitric acid and citric acid into the dry powder one by one, and knead until it can be extruded. Extruded once each through an empty plate and a cylindrical orifice plate with a diameter of 8 mm, and finally formed into a butterfly-shaped bar with a diameter of 1.6 mm; the obtained wet bar was first cured in an oven at 30°C for 24 hours, and then dried in an oven at 120°C for 8 hours. Finally, it was placed in a muffle furnace and the temperature was programmed to rise to 550° C. for 4 h to obtain the carrier ZT-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com