Method for preparing hydrocracking catalyst containing hierarchical pore Beta molecular sieve

A hydrocracking and molecular sieve technology, applied in the field of catalysis, can solve the problems of single, low catalyst activity, and limited mass transfer and conversion of macromolecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

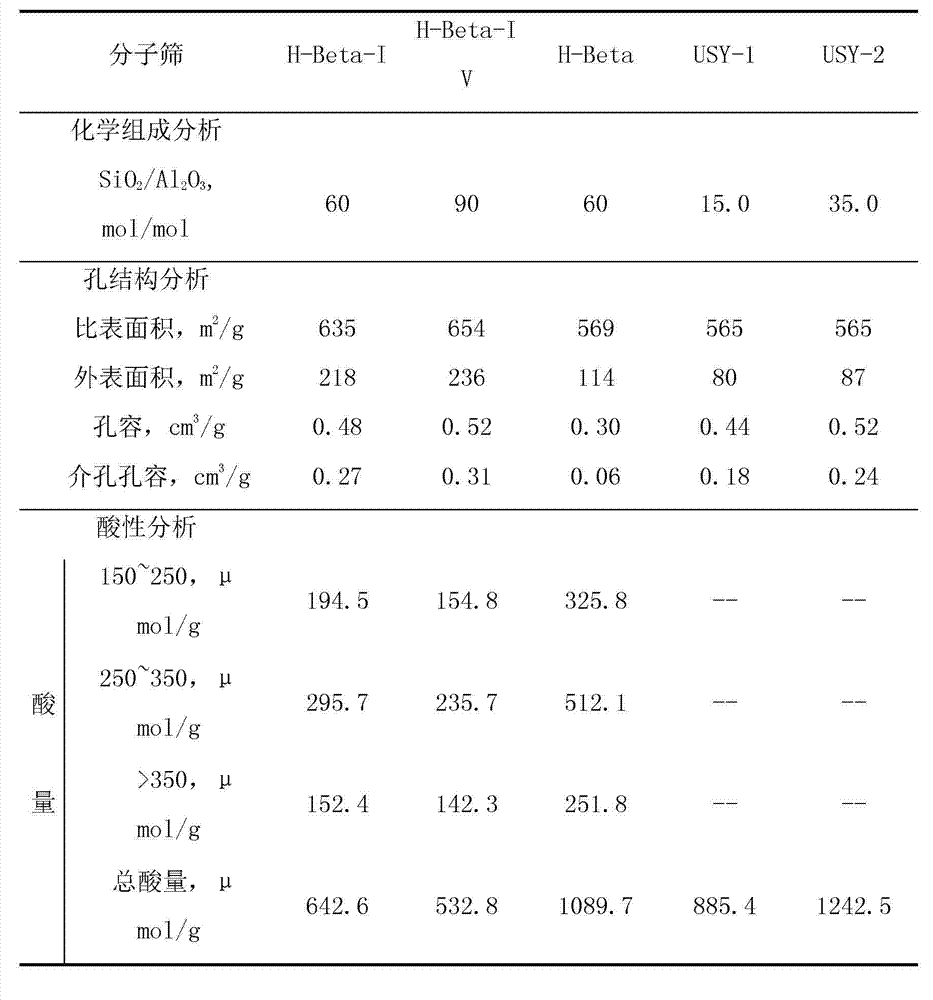

[0022] 1.0 g NaOH (analytically pure, NaOH ≥ 96wt.%) and 2.1 g NaAlO 2 (chemically pure, Al 2 o 3 , 41%) and 36.9 g TEAOH solution (industrial grade, 25wt%) were mixed evenly, and 102.9 g silica sol (industrial grade, SiO 2 ≥ 30wt.%), continue stirring for 2 h, add 26.7 g of hexadecyltrimethoxyorganosilicon quaternary ammonium salt (TPHAC) ethanol solution with a mass concentration of 10%, mix well to form a gel system, and the feeding of each reactant The molar ratio is: SiO 2 / Al 2 o 3 =60, SiO 2 / Na 2 O=43, SiO 2 / TEAOH=0.12,H 2 O / SiO 2 =3,TPHAC / SiO 2 =0.010, after continuing to stir for 2 h, put the resulting gel mixture into a polytetrafluoroethylene high-pressure reactor and adopt segmental dynamic crystallization, prior to 100 o After crystallization of C for 16 h, then with 10 o C / h heating rate to 155 o C degree, constant temperature crystallization for 72 h; the crystallized product was separated by filtration, and the solid product was washed with deio...

Embodiment -2

[0025] With the 2.1 g NaAlO in the embodiment 1 2 Change to 1.6 g NaAlO 2 , so that the SiO in the feed 2 / Al 2 o 3 The molar ratio is 90, and the remaining components and synthesis operating conditions are the same as in Example 1 to obtain a hierarchically porous H-Beta-II molecular sieve, whose physical and chemical properties are shown in Table-1.

Embodiment -3

[0029] Stir and mix 100 g NaY molecular sieve (Wenzhou) with 1000 g of 3% ammonium nitrate solution at 90 o Stir for 6 h at a constant temperature at C, filter with suction, wash with water three times, 120 o C drying 8 h, 520 o C roasting for 4 h, repeat the exchange operation three times; 550 o C hydrothermal treatment for 2 h, pressure 0.2 MPa; put 60 g of powder after hydrothermal treatment into a three-necked flask, then add 600 mL of 0.2 mol / L citric acid solution, at 90 o After mechanical stirring and reflux at C temperature for 4 h, the mixed turbid liquid was put into a polytetrafluoroethylene autoclave at 160 o After dynamic hydrothermal treatment at C temperature for 12 h, carry out suction filtration and separation, wash with water until neutral, and in 120 o C dried for 12 h to obtain the modified USY-1 molecular sieve. The SiO of gained H-Y molecular sieve 2 / Al 2 o 3 =15.0, the unit cell parameter is 2.438, the pyridine infrared acid content is 0.423 mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com