Preparation method of hydrocracking catalyst

A cracking catalyst and hydrocracking technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of large loss of octane number of gasoline products, reduce hydrogen saturation of gasoline components, and nitrogen resistance. To achieve the effect of reducing reaction hydrogen consumption, reducing hydrogen saturation, and high nitrogen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

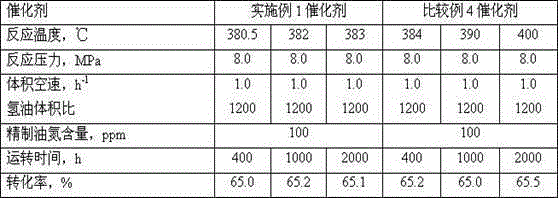

Examples

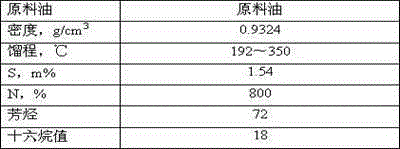

Embodiment 1

[0051] (1) Take Y molecular sieve with a dry basis weight of 300g and dry basis weight of 100g macroporous alumina, mix evenly, add 3g / 100ml dilute nitric acid 200ml, roll and extrude, then dry at 120°C for 4h, and roast at 550°C After 3 hours, the carrier was obtained, and the number was T-1; (2) Mo-Co impregnation solution was prepared: ammonium molybdate and cobalt nitrate were dissolved in water and the impregnation solution was prepared. The active metal in the obtained impregnation solution was MoO 3 and CoO content are calculated as 20g / 100ml and 6g / 100ml respectively, coded as RY-1; take 300g of T-1 and immerse in 600ml RY-1 for 2h, then take out the carrier at room temperature for 2h, dry at 100°C for 4h, and 500°C Roast for 3 hours to obtain a low metal content carrier, numbered CTL-1; (3) Take 300g of CTL-1 and place it in 600ml of n-heptane solvent for immersion for 2 hours, take it out and dry it at 110°C for 5 minutes to obtain CTL-2. The volume content in the ca...

Embodiment 2

[0053] (1) Take Y molecular sieve with a dry basis weight of 200g and dry basis weight of 200g macroporous alumina and mix evenly, add 3g / 100ml dilute nitric acid 200ml for rolling and extrusion, then dry at 120°C for 4 hours, and roast at 550°C After 3 hours, the carrier was obtained, and the number was T-2; (2) Mo-Co impregnation solution was prepared: ammonium molybdate and cobalt nitrate were dissolved in water and the impregnation solution was prepared. The active metal in the obtained impregnation solution was MoO 3 and CoO content are calculated as 18g / 100ml and 5g / 100ml respectively, and the code is RY-3; take 300g of T-2 and soak it in 800ml RY-3 for 2h, then take out the carrier at room temperature for 2h, dry at 100°C for 4h, and 500°C Roast for 3 hours to obtain a low metal content carrier, numbered CTL-3; (3) Take 300g of CTL-3 and place it in 600ml petroleum ether solvent for immersion for 2 hours, take it out and dry it at 90°C for 6 minutes to obtain CTL-4, petr...

Embodiment 3

[0055] (1) Take β molecular sieve with dry basis weight of 250g and dry basis weight of 150g macroporous alumina and mix evenly, add 200ml of 3g / 100ml dilute nitric acid for rolling and extrusion, then dry at 120°C for 4h, and roast at 550°C After 3 hours, the carrier was obtained, and the number was T-3; (2) Mo-Co impregnation solution was prepared: ammonium molybdate and cobalt nitrate were dissolved in water and the impregnation solution was prepared. The active metal in the obtained impregnation solution was MoO 3 and CoO content are calculated as 22.4g / 100ml and 6.7g / 100ml respectively, coded as RY-5; take 300g of T-3 and soak it in 600ml RY-5 for 2h, then take out the carrier and dry it at room temperature for 2h and then dry it at 100℃ for 4h. Calcined at 500°C for 3 hours to obtain a low metal content carrier, numbered CTL-3; (3) Take 300g of CTL-3 and place it in 600ml n-heptane solvent for immersion for 2h, take it out and dry it at 110°C for 5 minutes to obtain CTL-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com