Catalytic cracking diesel oil hydro-upgrading catalyst and application thereof

A technology for catalytic cracking diesel oil and hydro-upgrading, which is applied to catalysts containing molecular sieves and application fields, can solve the problems of high operation and investment costs, high initial boiling point of diesel raw materials, harsh operating conditions, etc., and achieves equipment investment and operating costs. Low, enhance the ability of macromolecule conversion, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

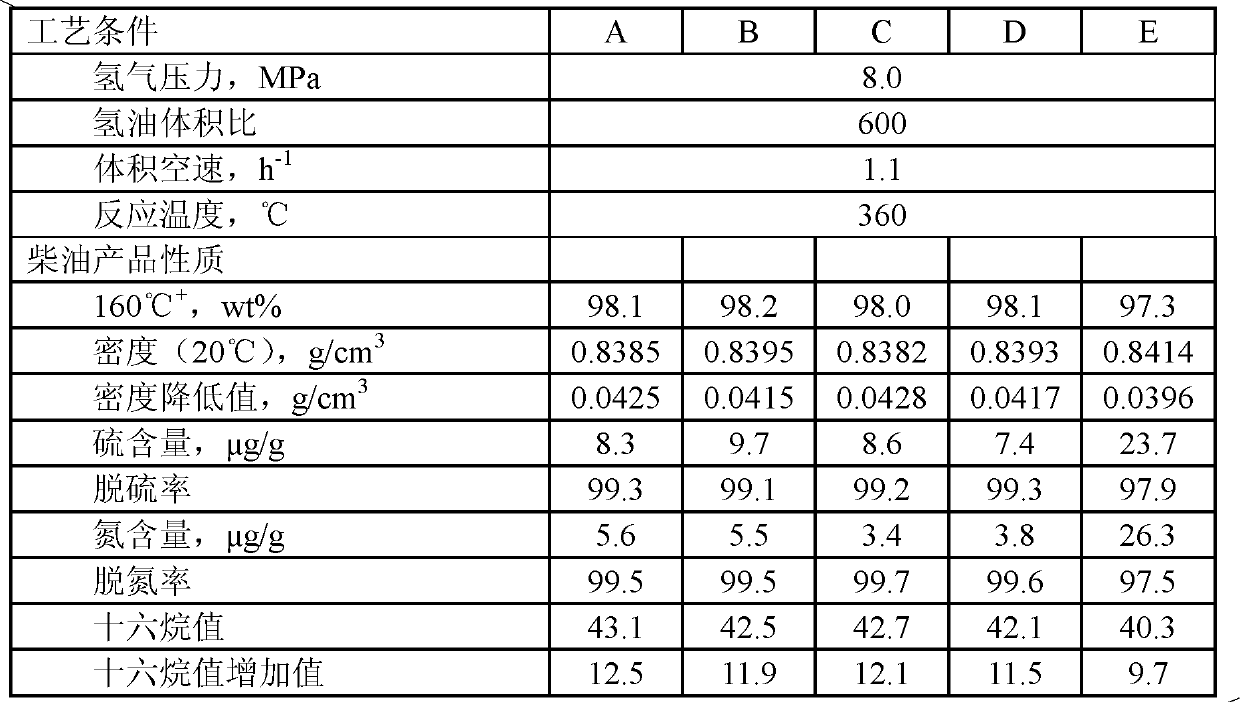

Examples

Embodiment 1

[0032] Get 100 grams of nanometers (average grain size 87nm) NaY molecular sieve (crystallinity is 97%, SiO 2 / Al 2 o 3 The molar ratio is 5.6, Beijing Bowen Kefeng Technology Development Co., Ltd.), added to the 70g NH 4 In the 1000ml aqueous solution of Cl, exchange at 80°C for 1 hour. During this process, the pH value is controlled to 3.4. After the exchange, filter, wash, and dry, and then treat it in a muffle furnace at a temperature of 600°C for 2 hours; then follow the same procedure conditions for the second ammonium exchange, after the exchange, filter, wash, and dry, and then treat for 2 hours in a 100% water vapor atmosphere at a temperature of 610°C and a water vapor pressure of 0.2 MPa; the finally obtained modified Y Molecular sieve SiO 2 / Al 2 o 3 The molar ratio is 15, the relative crystallinity is 79%, the average grain size is 80nm, and the specific surface area is 713m2 / g.

Embodiment 2

[0034] Get 100 grams of nanometers (average grain size 87nm) NaY molecular sieve (crystallinity is 97%, SiO 2 / Al 2 o 3 The molar ratio is 5.6, Beijing Bowen Kefeng Technology Development Co., Ltd.), added to the 70g NH 4 NO 3 In 1000ml of aqueous solution, exchange at 80°C for 1 hour. During this process, the pH value is controlled to 3.1. After the exchange, filter, wash, and dry, and then treat it in a muffle furnace at a temperature of 600°C for 2.5 hours; then follow the same conditions Carry out the second ammonium exchange, filter after the exchange, wash with water, dry, and then treat for 2 hours in a 100% water vapor atmosphere at a temperature of 600°C and a water vapor pressure of 0.15 MPa; the finally obtained modified Y molecular sieve SiO 2 / Al 2 o 3 The molar ratio is 18, the relative crystallinity is 81%, the average grain size is 84nm, and the specific surface area is 693m2 / g.

Embodiment 3

[0036] Get modified Y molecular sieve 25.5g in embodiment 1, and 82.9g alumina (for example, the pseudo-boehmite produced by SASOL company, wherein the gibbsite content is 70wt%), 27.2g amorphous silicon aluminum, 4.7g scallop powder, after mixing, add dropwise a mixed solution of 6.5g concentrated nitric acid (96wt%), 4.3g citric acid and 108g water, extrude into a clover shape of about 1.3mm, dry at 110°C, and air atmosphere at 500°C Roast for 4 hours. Then immerse in a solution of 33g of nickel nitrate and 50g of ammonium metatungstate dissolved in 50ml of water for 2 hours, dry at 110°C, and roast at 480°C for 4 hours in an air atmosphere to obtain catalyst A. According to specific requirements, it can be crushed or cut into the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com