Biomass pyrolysis reactor and working method thereof

A biomass pyrolysis and pyrolysis reaction technology, applied in the field of biomass pyrolysis reactors, can solve the problems of secondary cracking of pyrolysis oil and gas, insufficient pyrolysis, mixing of heat carrier gas and particles, etc. time, ensure uniform mixing, and the effect of rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

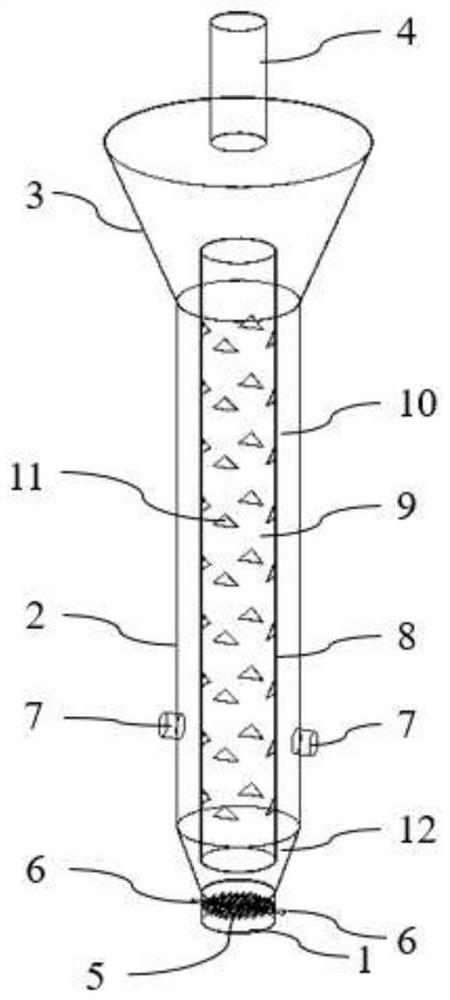

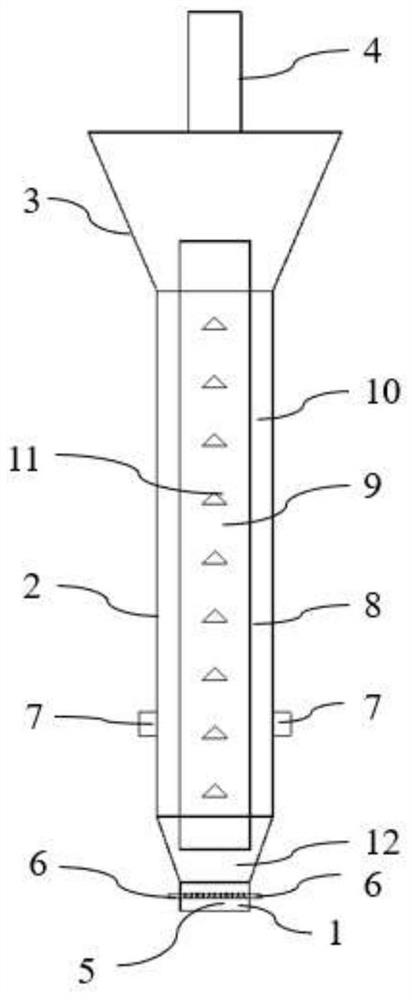

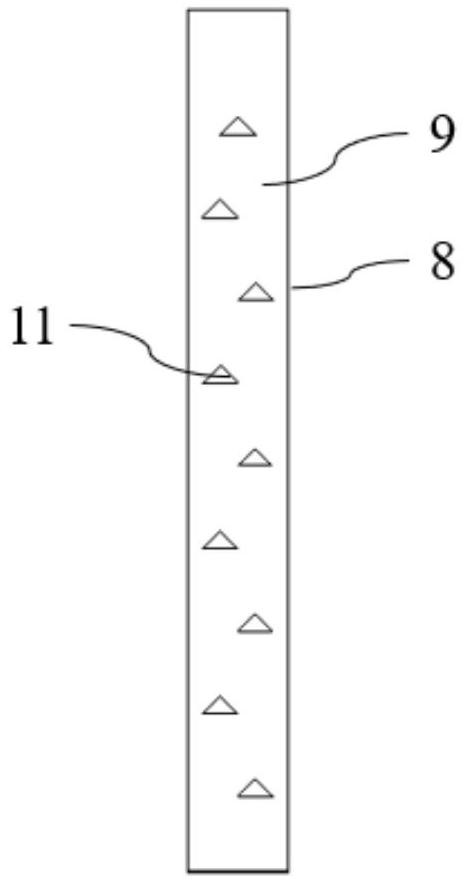

[0034] see Figure 1 to Figure 7 , in this embodiment, a biomass pyrolysis reactor, including a pyrolysis product delivery section 4, a reactant and product separation section 3, a circular flow pyrolysis reaction section 2, and a heat carrier gas inlet section arranged in sequence from top to bottom 1. The pyrolysis product delivery section 4, the reactant and product separation section 3, the circular pyrolysis reaction section 2 and the heat carrier gas inlet section 1 are connected in sequence.

[0035] In this embodiment, the pyrolysis product conveying section 4 is used to quickly lead the pyrolysis oil and gas products to the biomass pyrolysis reactor, and weaken the secondary cracking reaction of pyrolysis oil and gas; the height of the pyrolysis product conveying section 4 is for the circulation pyrolysis reaction 10% of the height of section 2; the diameter of pyrolysis product delivery section 4 is 10% of the diameter of loop pyrolysis reaction section 2.

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com