Low-grade heavy oil catalytic conversion process for increasing yield of low-carbon olefins and diesel oil

A low-quality heavy oil and catalytic conversion technology, applied in the field of catalytic conversion of heavy oil, can solve the problems of reducing diesel yield, increasing the load of hydrogenation unit, and reducing aromatic compounds, so as to reduce the yield of dry gas and coke, Effect of prolonging catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

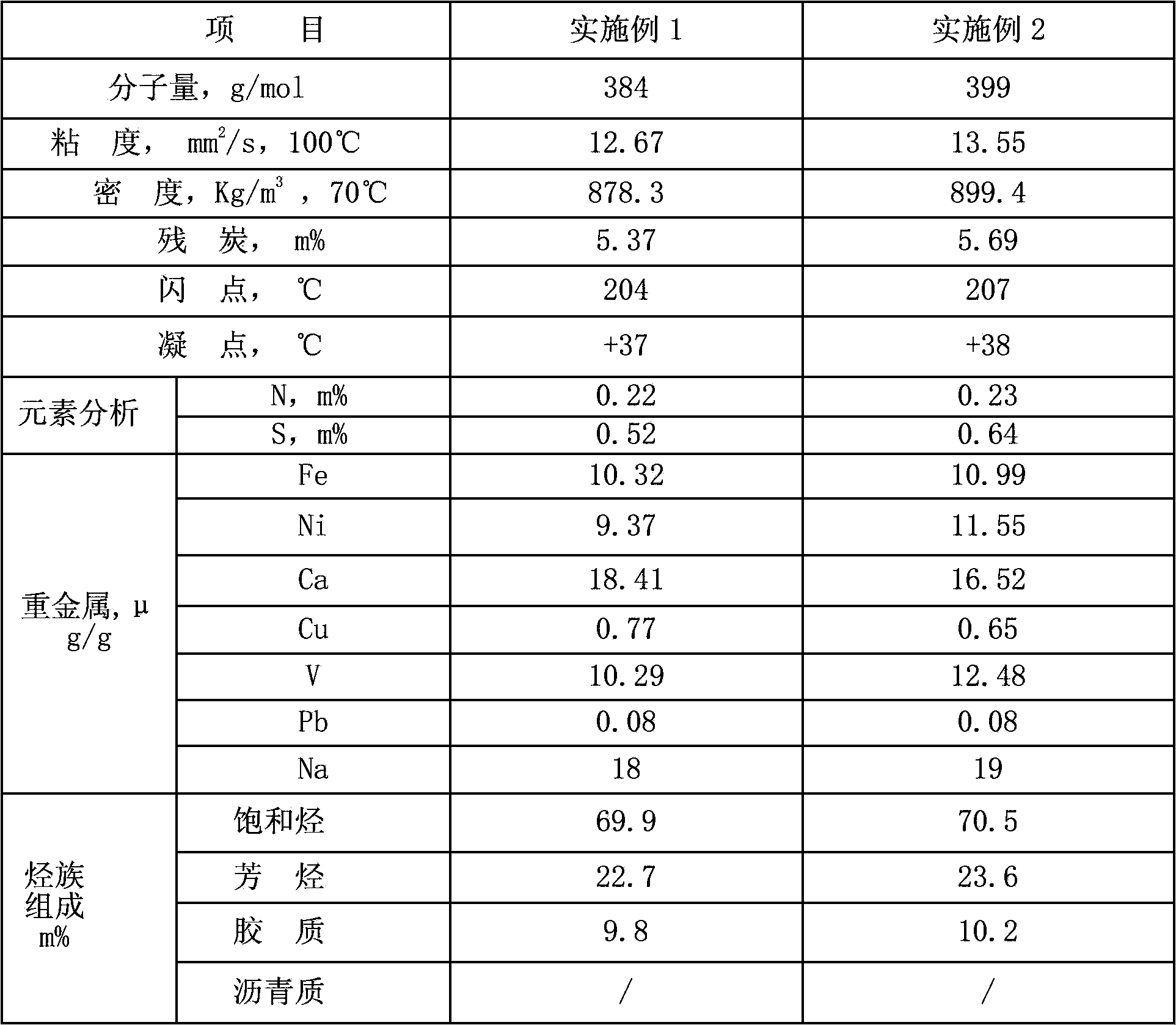

Embodiment 1

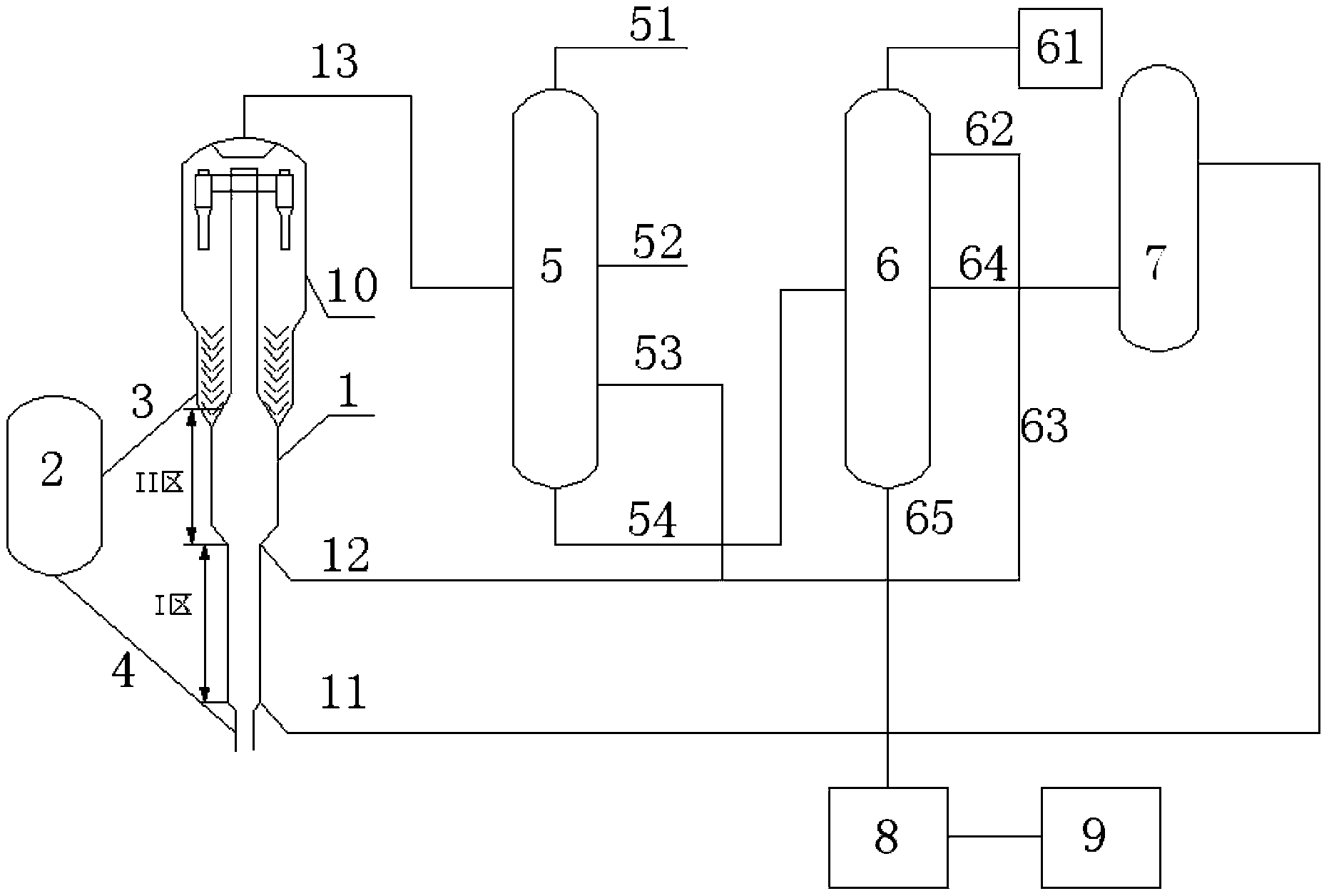

[0039] (1) The preheated low-quality heavy oil enters the bottom feed port 11 of the riser 1, and contacts with the catalytic cracking catalyst from the regenerated inclined pipe 4 at high temperature, short contact time, and large catalyst-to-oil ratio in the riser I area to carry out catalytic cracking reaction, High-temperature catalytic cracking reaction occurs under the reaction conditions of 650°C reaction temperature, 1.5 seconds reaction time, 12:1 weight ratio of catalyst to heavy hydrocarbon feedstock, and 0.3% weight ratio of water to heavy hydrocarbon feedstock.

[0040] (2) The generated oil gas and the raw materials from the lower outlet 53 of the fractionation tower and the upper outlet 62 of the vacuum distillation tower undergo a relatively mild catalytic cracking reaction, hydrogen transfer reaction and isomerization reaction in the riser II area. The catalyst with carbon deposits is separated from oil and gas in the settler 10, and the separated catalyst ente...

Embodiment 2

[0045] (1) The preheated low-quality heavy oil enters the bottom feed port 11 of the riser 1, and contacts with the catalytic cracking catalyst from the regenerated inclined pipe 4 at high temperature, short contact time, and large catalyst-to-oil ratio in the riser I area to carry out catalytic cracking reaction, The reaction temperature is 620°C. The reaction time is 1.8 seconds; the weight ratio of catalyst to heavy hydrocarbon feedstock is 11:1; the weight ratio of water to heavy hydrocarbon feedstock is 0.3% and the high temperature catalytic cracking reaction occurs.

[0046] (2) The generated oil gas and the raw materials from the lower outlet 53 of the fractionation tower and the upper outlet 62 of the vacuum distillation tower undergo a relatively mild catalytic cracking reaction, hydrogen transfer reaction and isomerization reaction in the riser II area. The catalyst with carbon deposits is separated from oil and gas in the settler 10, and the separated catalyst ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com