Closed type rough cyclone quick separation system carrying multiple-riser reactor for catalytic cracking process and catalytic cracking method thereof

A catalytic cracking and riser technology, which is applied in catalytic cracking, chemical instruments and methods, and devices in which the axial direction of the swirl flow can be reversed, etc., can solve the problems of reducing the work intensity of operators, improve product quality, and shorten the stay time, to achieve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

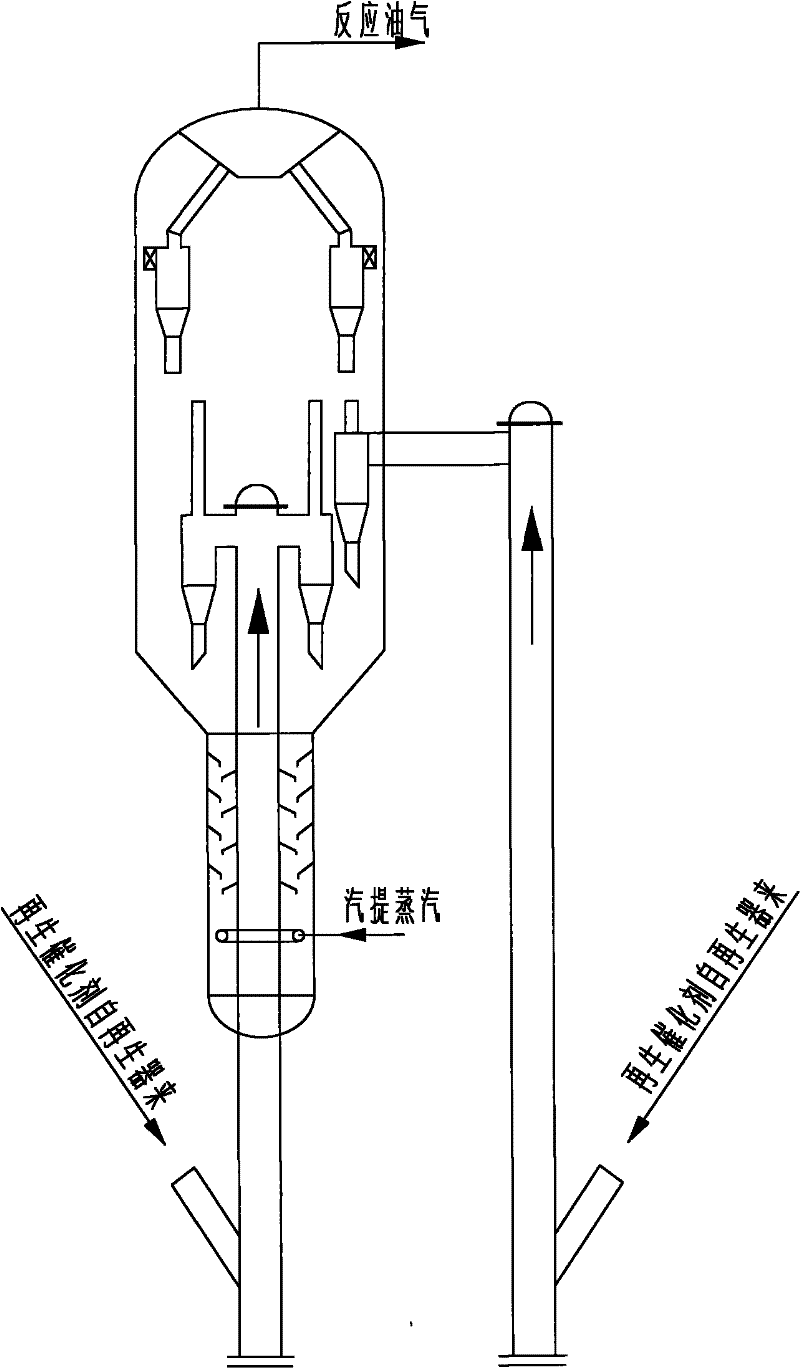

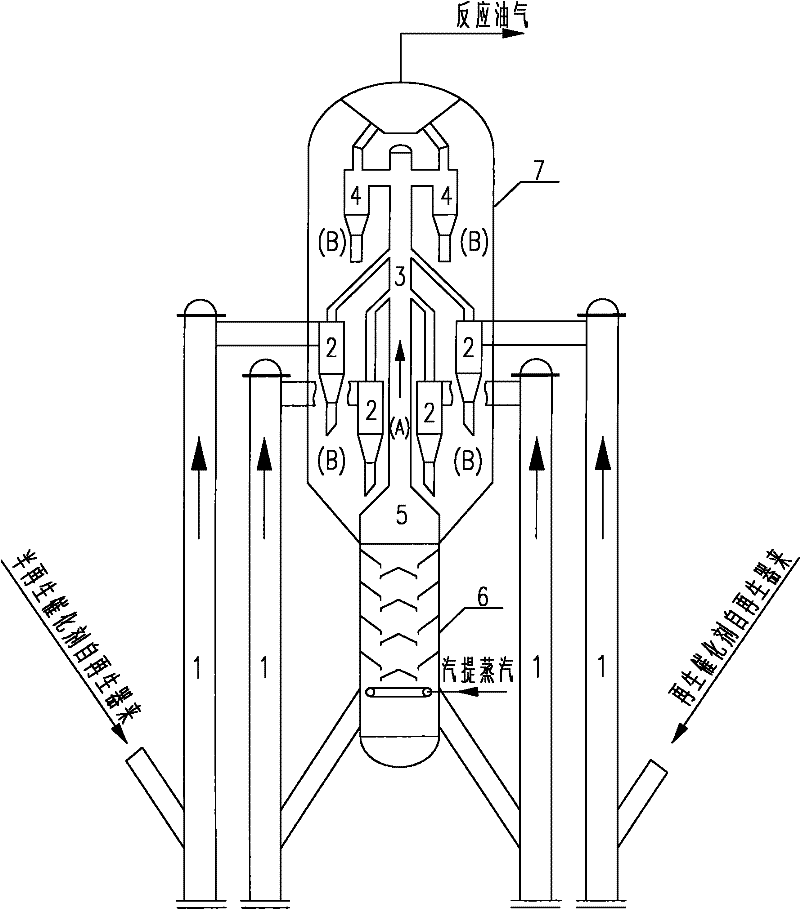

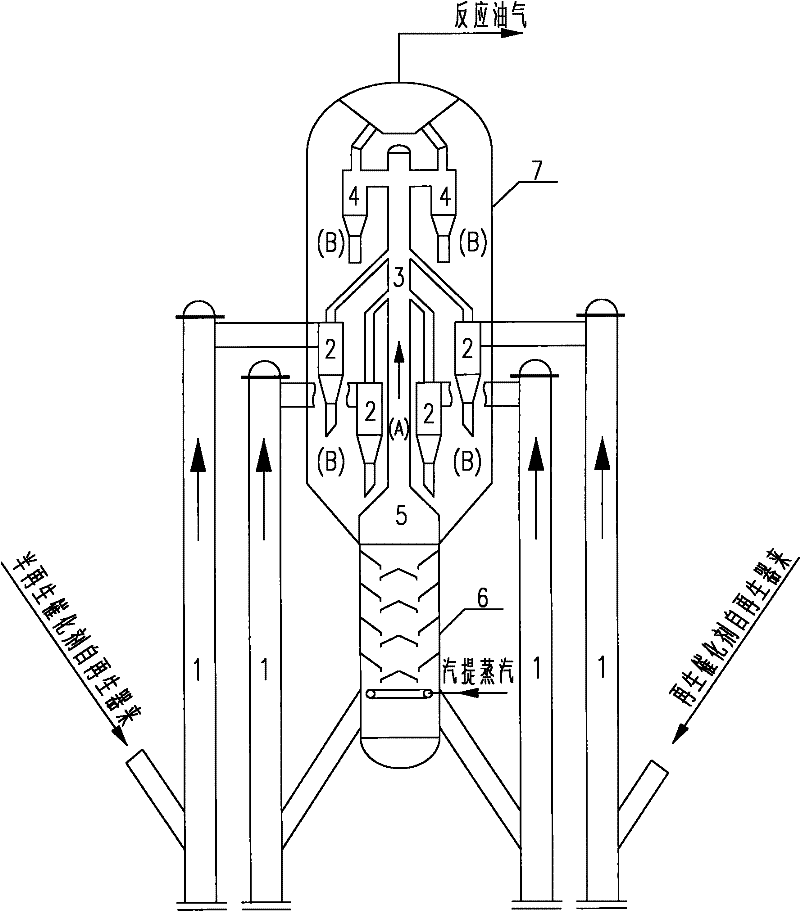

[0037] Such as figure 2 As shown, the closed multi-riser reactor with rough cyclone and rapid separation includes a riser 1 , a stripping section 6 , a reaction settler 7 , and a rough cyclone separator 2 and a top cyclone separator 4 therein.

[0038] In the reaction settler 7, the gas outlet pipes of each coarse cyclone separator 2 are airtightly connected directly to the inlet oil pipes of each cyclone separator 4 at the top through a straight oil-gas collecting pipe 3 to form a closed quick separation system.

[0039] The inside of the reaction settler 7 is provided with a stripping steam collection cover 5 composed of an upper conical cylinder and a lower straight cylinder, and the bottom of the reaction settler 7 is embedded in the lower position of the stripping steam collection cover 5 . The top of the conical cylinder on the upper part of the stripping steam collection cover 5 is connected to the bottom of the oil-gas collecting pipe 3, and the straight cylinder on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com