Hydrocracking method

A hydrocracking and hydrorefining technology, which is applied in the directions of hydrotreating process, hydrocarbon oil treatment products, and hydrocarbon oil treatment, etc., can solve the problems of low improvement of jet fuel quality, low economic benefit, limited yield of chemical raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

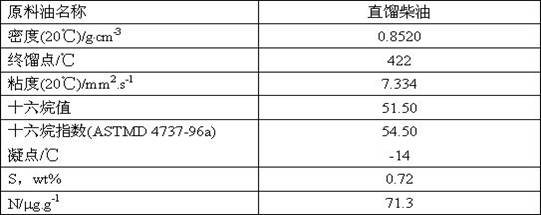

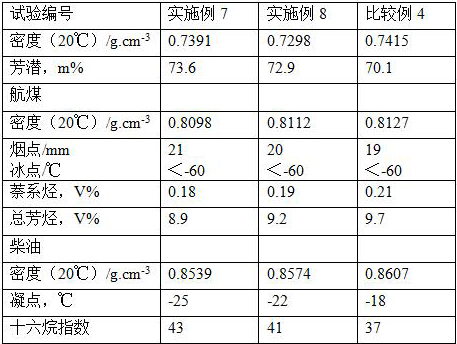

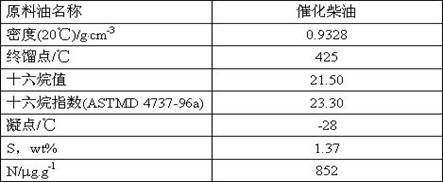

[0043] Using raw oil 1 as the raw material, two catalyst beds are set in the hydrofinishing reactor, and three catalyst beds are set in the hydrocracking reactor. Catalyst I, catalyst II and catalyst III are loaded sequentially along the flow direction, and the catalyst loading volume ratio is 1:1:1. See Tables 4 and 5 for specific hydrogenation reaction conditions, product distribution and properties.

Embodiment 2

[0045] Same as Example 1, two catalyst beds are set in the hydrotreating reactor, the difference is that the catalyst loading volume ratio is 2:1:1. See Tables 4 and 5 for specific hydrogenation reaction conditions, product distribution and properties.

Embodiment 3

[0047] Same as in Example 1, two catalyst beds are set in the hydrotreating reactor, the difference is that the catalyst loading volume ratio is 1:2:1. See Tables 4 and 5 for specific hydrogenation reaction conditions, product distribution and properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com