Fluidized bed grading differential temperature pyrolysis device and method for low heating value viscous solid fuel

A solid fuel, low-temperature pyrolysis technology, which is used in direct heating and dry distillation, petroleum industry, coke ovens, etc. Simple, low carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

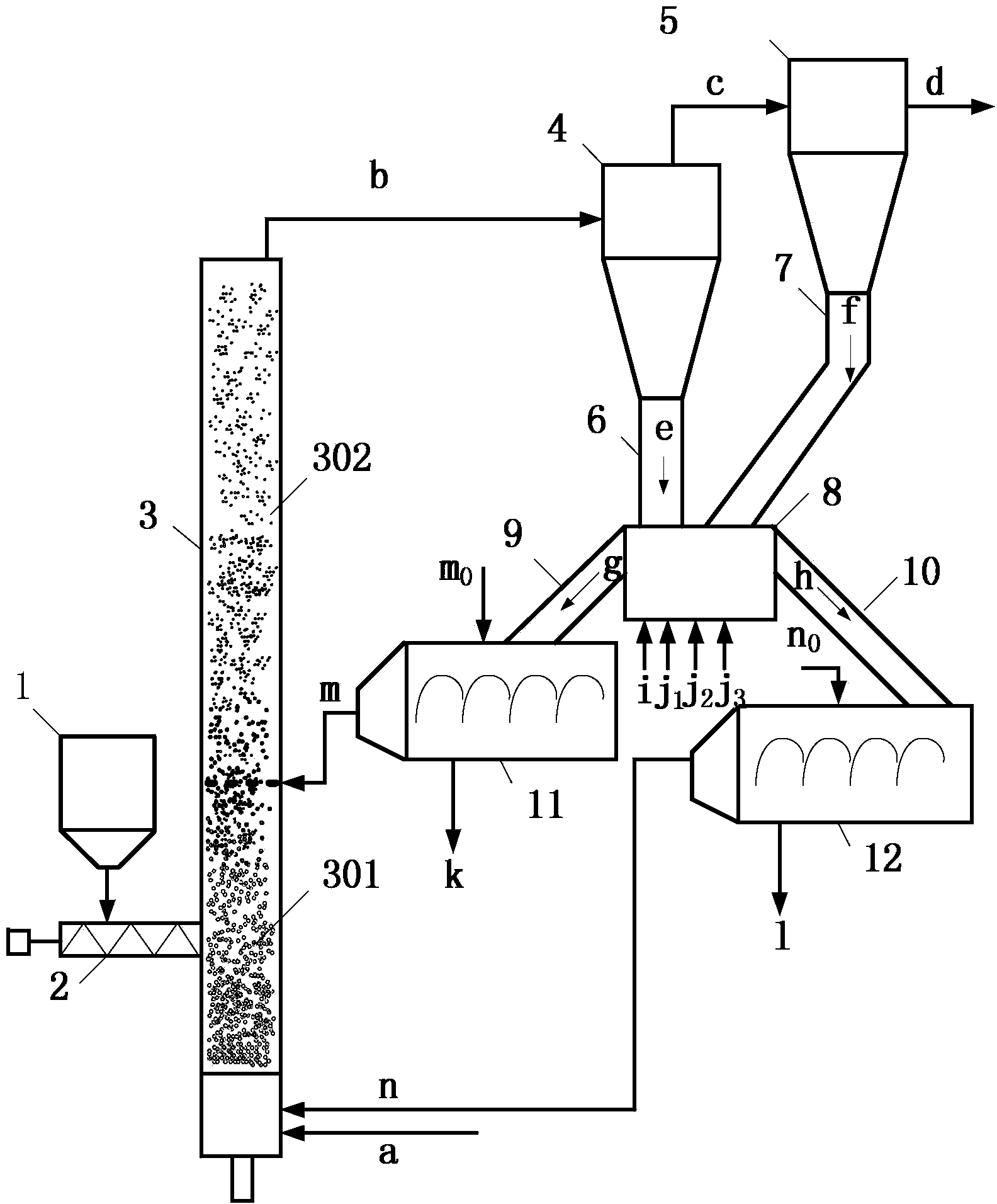

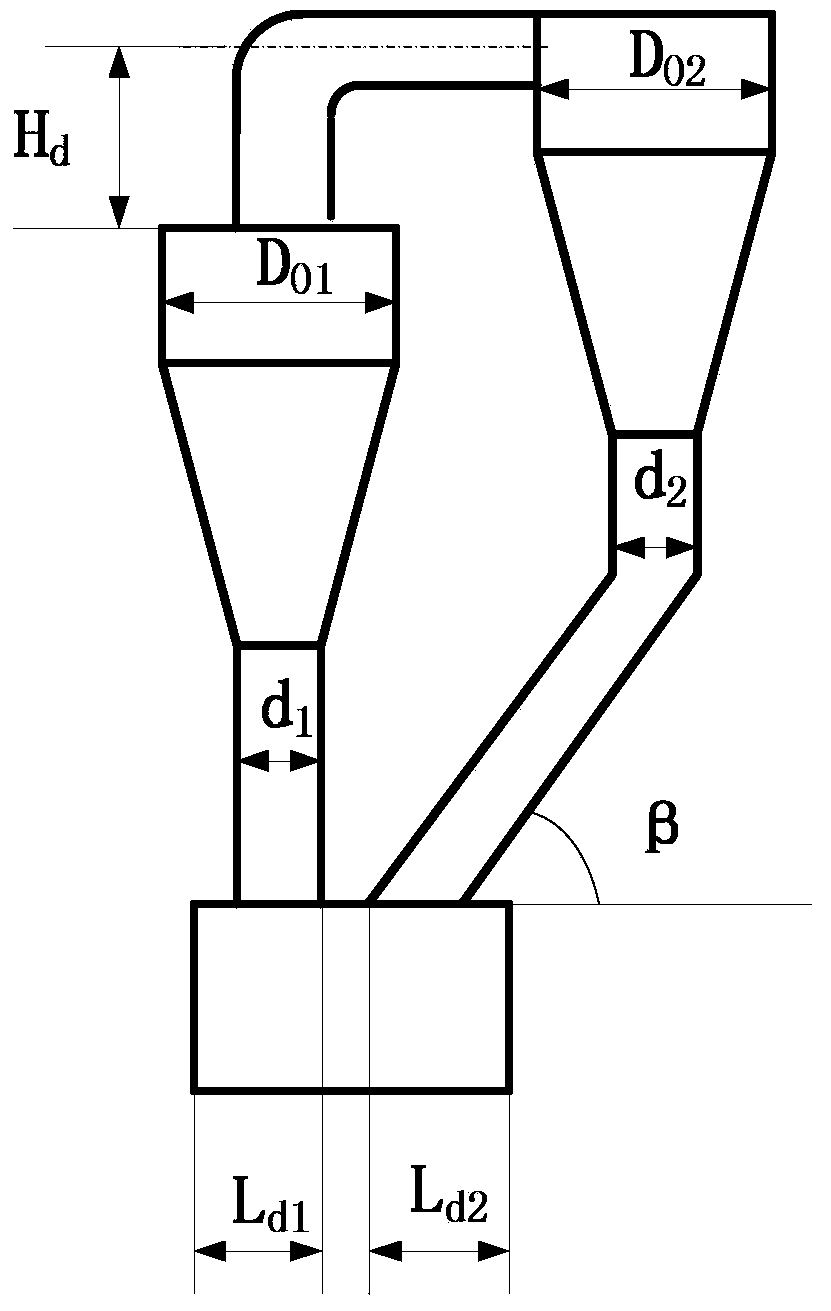

[0036] see Figure 1-5 , The fluidized bed staged differential temperature pyrolysis device of low calorific value viscous solid fuel provided by the present invention, the device includes a fluidized bed pyrolysis reactor 3, a two-stage high-efficiency cyclone separator and its first-stage cyclone separator 4, a first-stage Downcomer 6, secondary cyclone separator 5, secondary downcomer 7, double-inlet two-way pneumatic return valve 8, first cyclone burner 12, second cyclone burner 11.

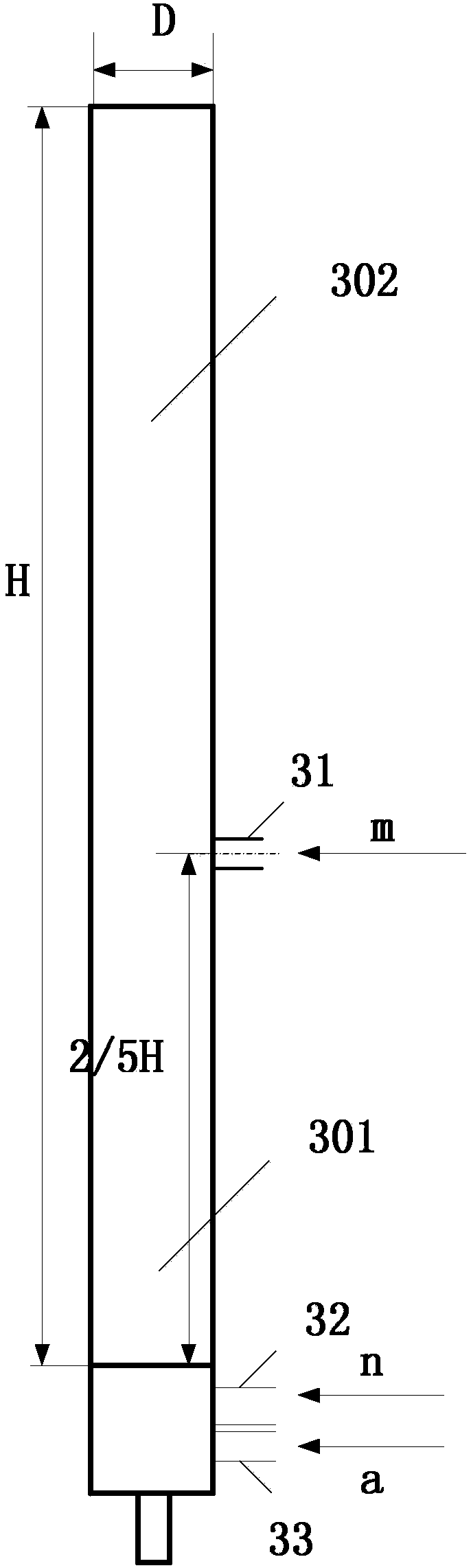

[0037] The outlet of the fluidized bed pyrolysis reactor 3 is connected in series with the primary cyclone separator 4, and the fluidized bed pyrolysis reactor 3 is respectively a primary low temperature pyrolysis section 301 and a secondary low temperature pyrolysis section 302 from bottom to top, wherein , the bottom of the secondary low-temperature pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com