High-efficiency oily sewage treatment device and method

A technology of sewage treatment device and sewage treatment method, which is applied in water/sewage treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., and can solve short residence time, secondary pollution, and uneven distribution of microbubbles and other problems to achieve the effect of improving the separation effect of air flotation and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and examples, and the innovativeness of the oily sewage treatment method of the present invention falls within the scope of protection of the present invention.

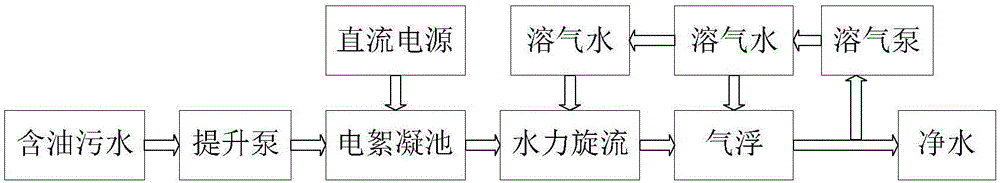

[0044] Such as figure 1 As shown, the oily sewage is pumped out by the lifting pump and sent to the electroflocculation tank 8 after pressurization, and the sewage is electrolyzed by the electrode plate 9 to generate complexes to absorb oil droplets; sewage containing flocculent complexes flows into the hydrocyclone body 11 for cyclone separation and removal of flocs and large oil droplets in the water; the preliminarily separated sewage enters the air flotation body 12 for air flotation separation. The method can effectively remove impurities such as oil droplets, silt, colloid, dissolved organic matter and heavy metal ions in the oily sewage, and finally obtain purified water.

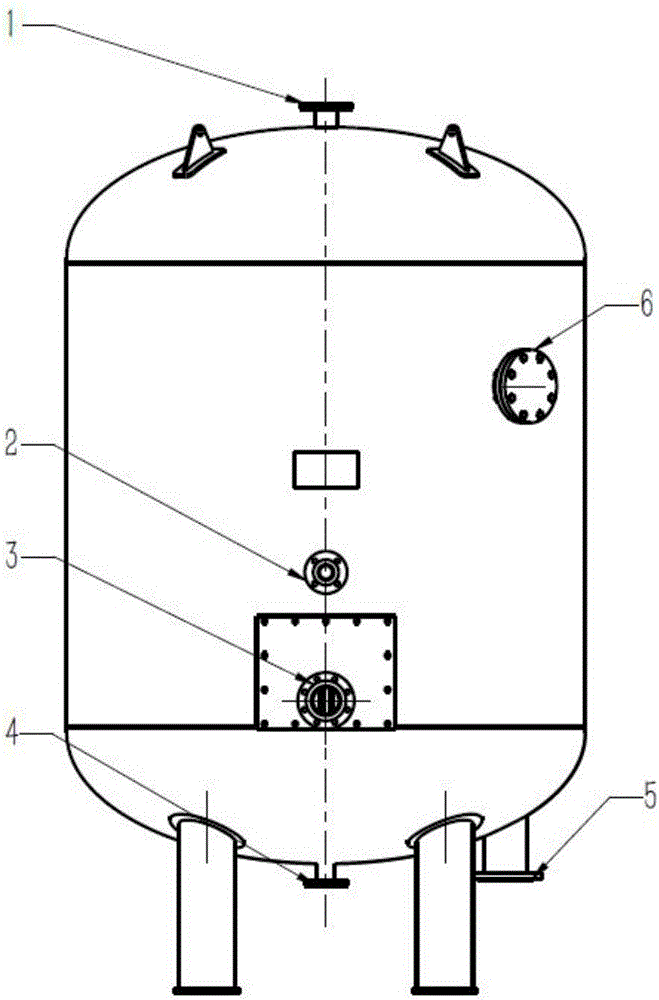

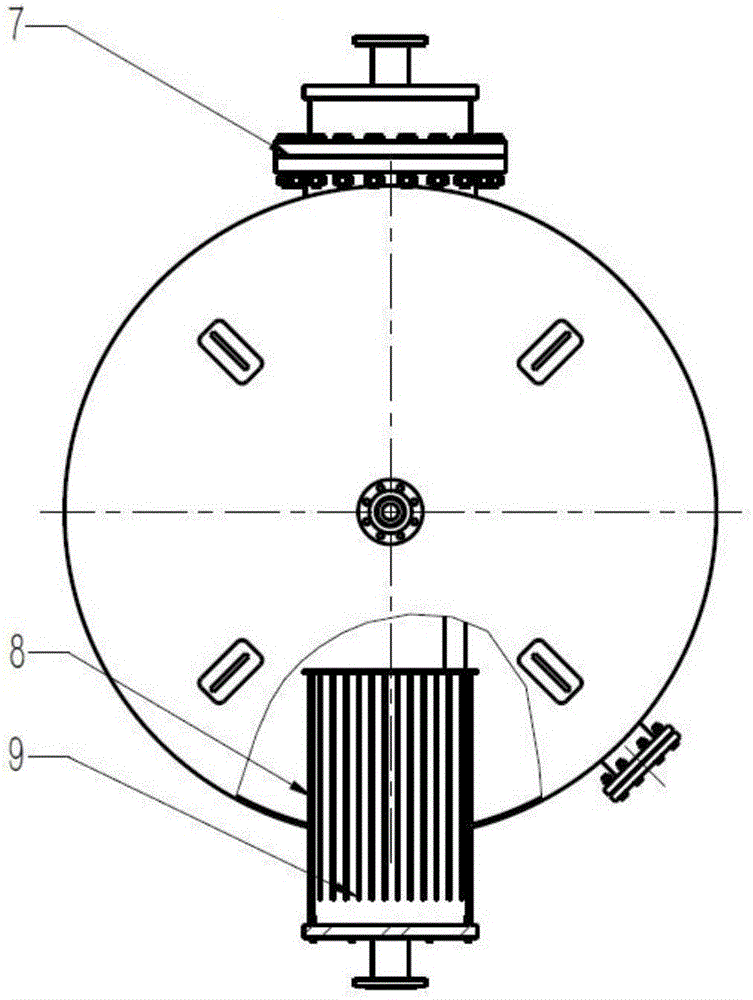

[0045] Such as figure 2 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com