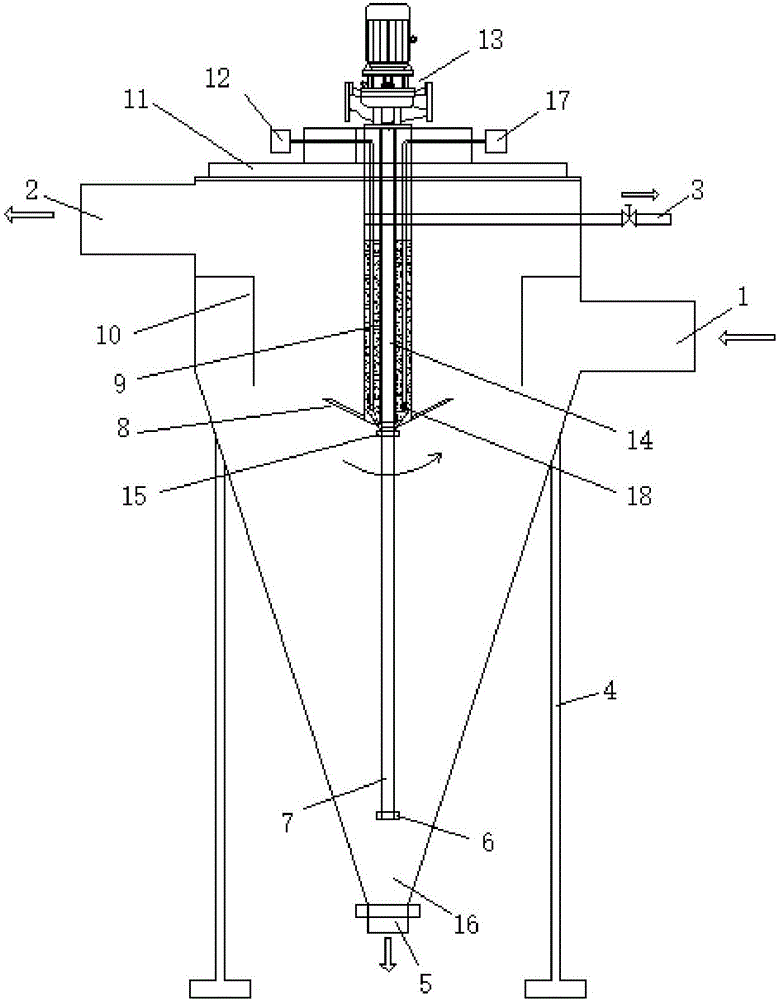

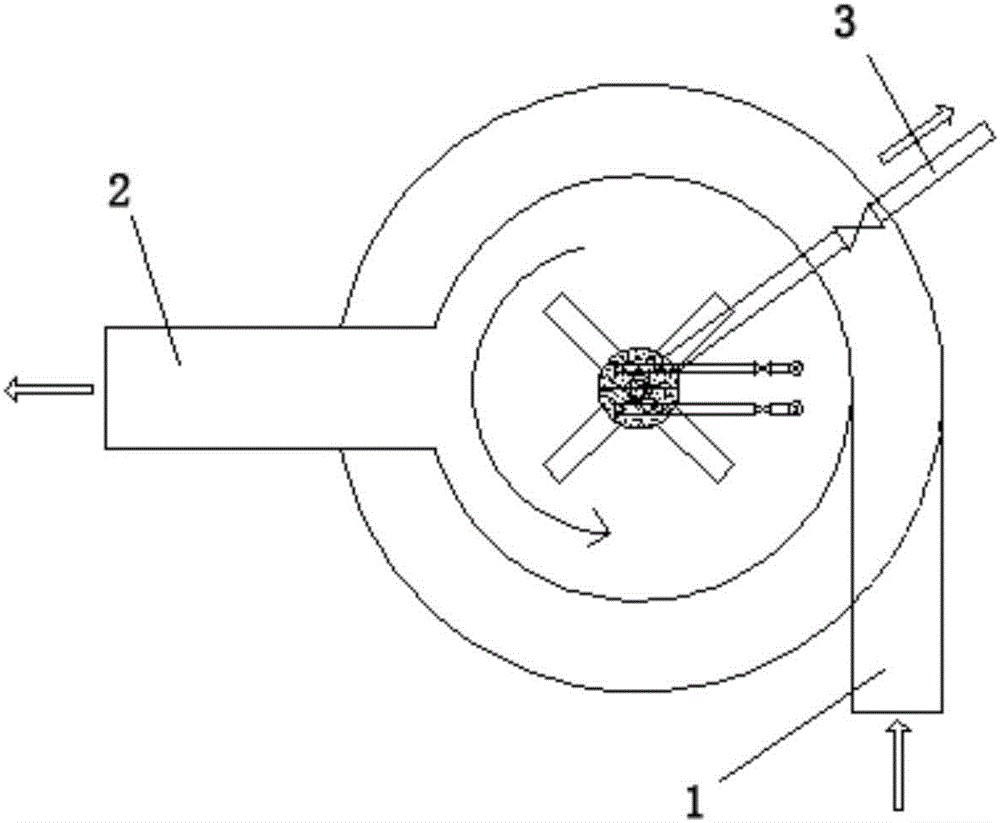

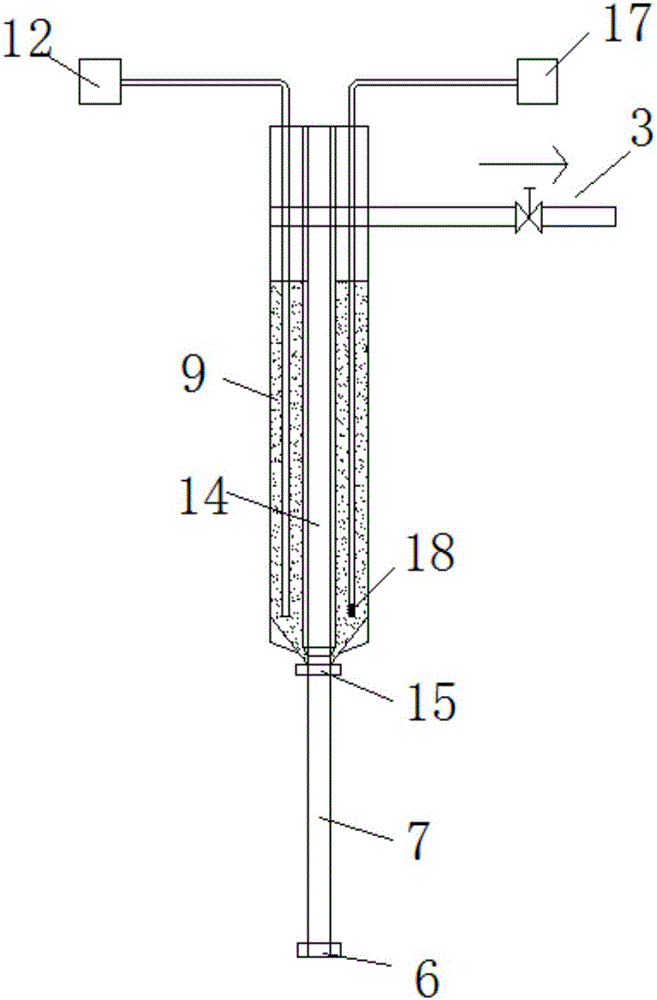

Rotating sand settling device and technology

A technology for sand settling and equipment, which is applied in the direction of settling tanks, sedimentation separation, and pumps on precipitators, etc. It can solve problems such as unstable operation, low water inflow speed, and low processing efficiency of sand particles larger than 35 μm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A grit chamber with a diameter of 1.8m and a height of 3m is designed to treat urban sewage whose influent sand particle size is 25-45μm, accounting for 90% of an urban sewage plant. Orthogonal experiments were carried out at water inlet speeds of 4m / s, 3m / s, and 2m / s, hydraulic retention times of 40s, 50s, and 60s, and stirring linear speeds of 0.7m / s, 0.6m / s, and 0.5m / s. The particle size of effectively separated sand particles is ≥ 25 μm as a reference index. The results show that the treatment effect is the best when the water inlet speed is 3m / s, the hydraulic retention time is 60s, and the stirring line speed is 0.6m / s. The minimum sand separation rate is 90.73%, and the maximum is 94.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com