Slurry organic solid waste pyrolysis device and method

A technology of pyrolysis of organic solid waste, which is applied in pyrolysis treatment of sludge, treatment of hydrocarbon oil, vaporization of by-products, etc., can solve the problems of uneven heating, ineffective transportation, low pyrolysis efficiency, etc., and achieve uniform heating, Reduce secondary cracking reaction and high pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

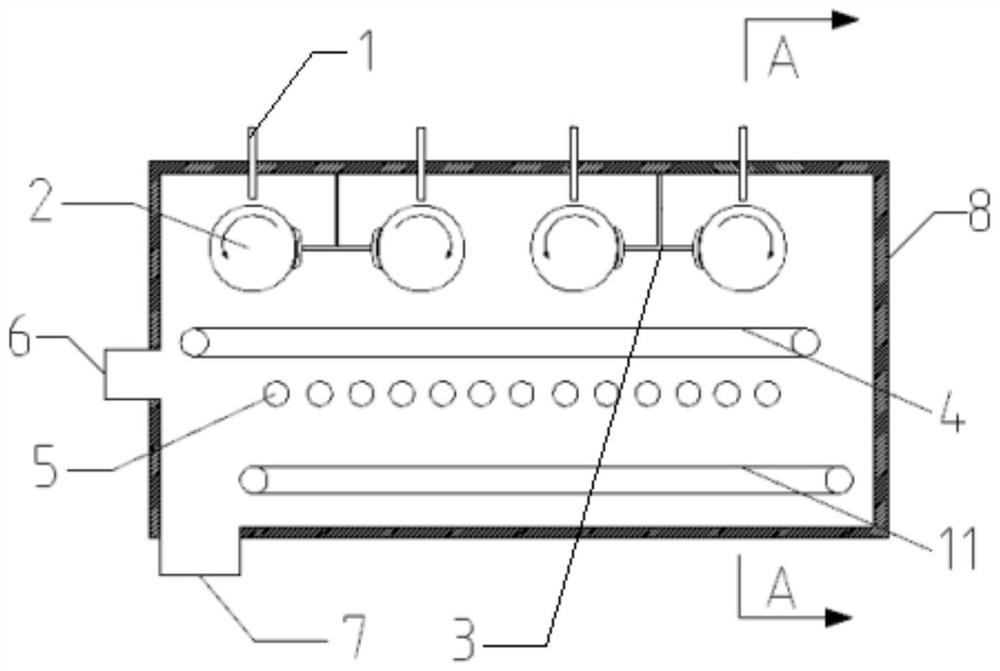

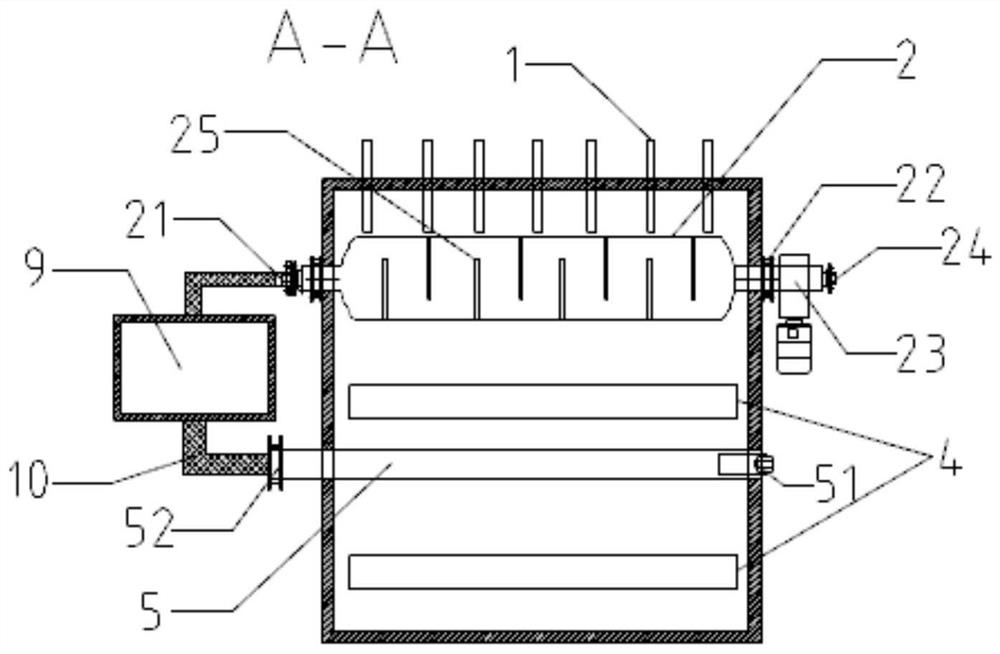

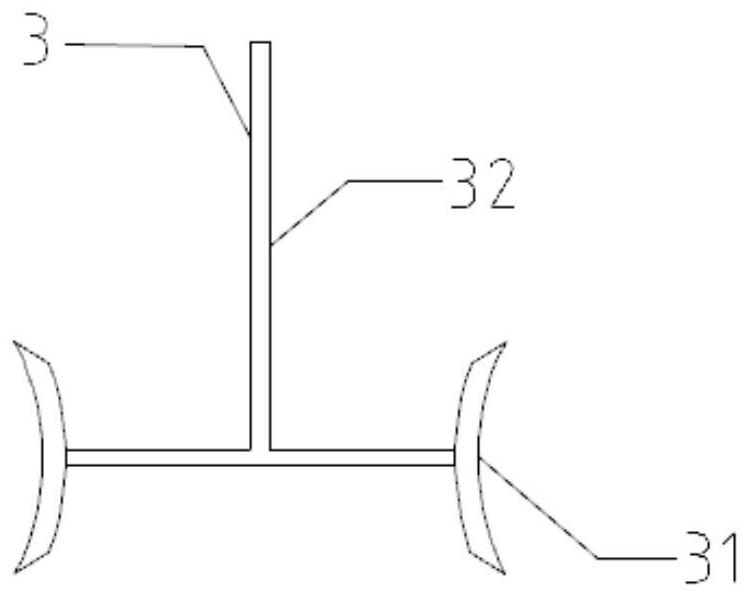

[0029] see Figure 1-Figure 3 , a slurry organic solid waste pyrolysis device according to the present invention, comprising a casing 8, a feed inlet 1 is arranged at the top of the casing 8, and a heating drum 2 is rotatably installed below the feed inlet 1, and the heating drum 2 One end passes through one side of the shell 8 and is connected to the motor drive; coke cleaners 3 are installed on both sides of the heating drum 2; an upper chain plate 4 and a lower chain plate 11 are horizontally arranged below the heating drum 2, the The output end of the upper chain plate 4 corresponds to the input end of the lower chain plate 11; a row of horizontally arranged heating tubes 5 is installed between the upper chain plate 4 and the lower chain plate 11; Gas port 6 and pyrolytic charcoal outlet 7, the pyrolytic charcoal outlet 7 is located at the bottom of the shell 8 and corresponds to the output end of the lower chain plate 11.

[0030] 4 to 8 feed ports 1 are evenly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com