Hydrogenation method for reducing condensation point of diesel oil

A diesel and freezing point technology, which is used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of low yield of low-condensation diesel oil, etc., and achieve the effects of low sulfur content, improved selectivity, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

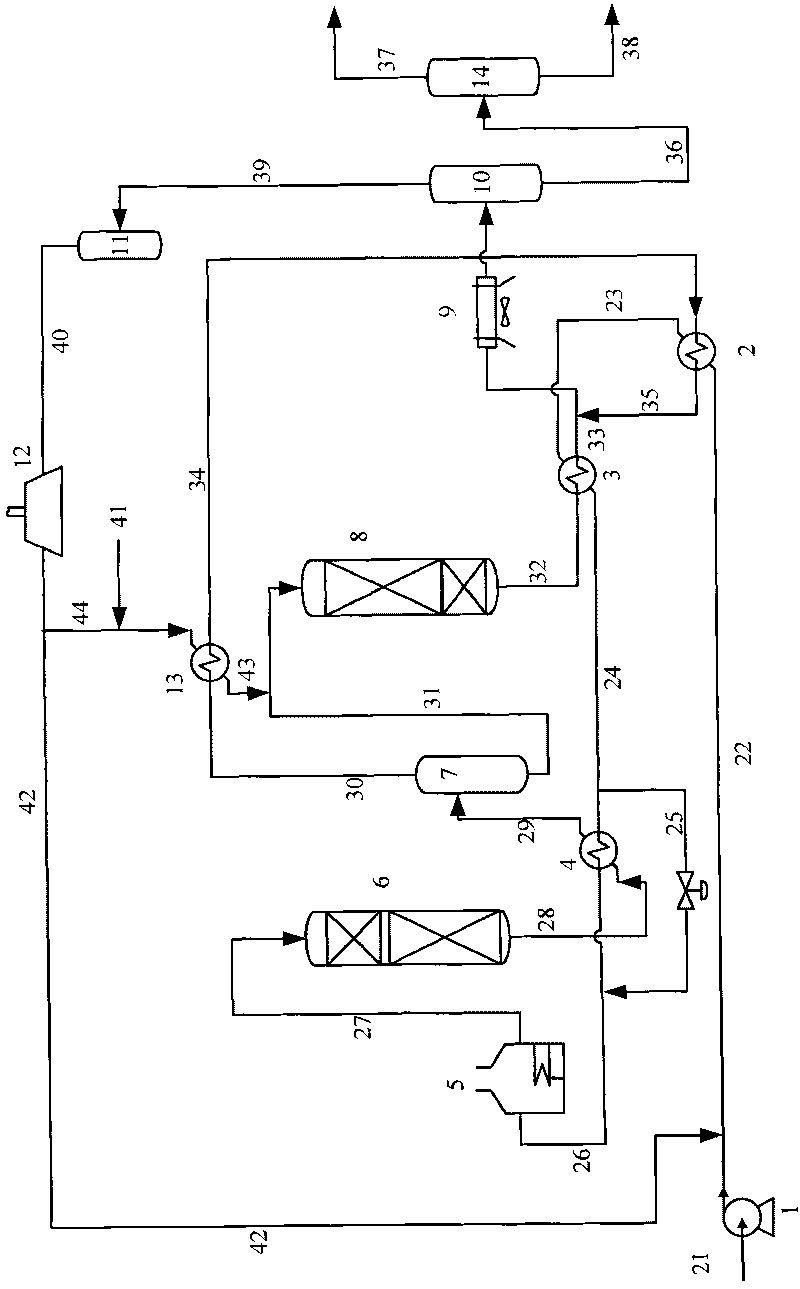

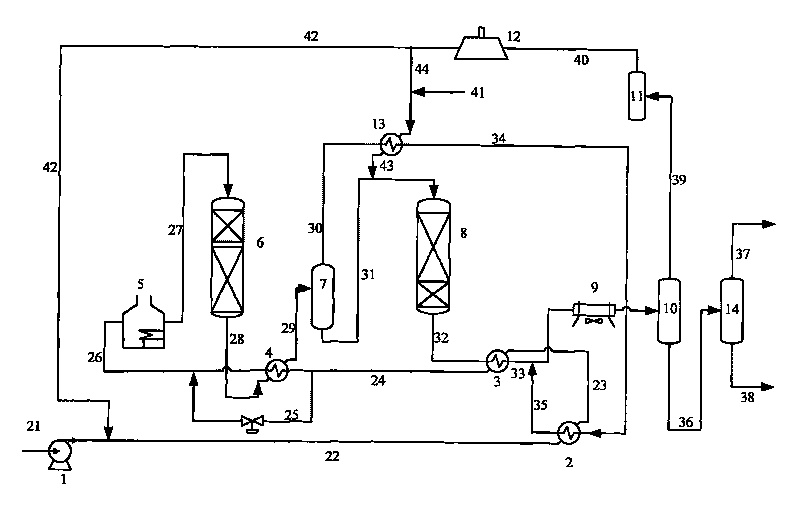

Method used

Image

Examples

Embodiment 1

[0043] A diesel oil fraction is used as raw material A, and the raw material A is first subjected to full-distillate hydrorefining in the first hydrogenation reaction zone. After the reaction product passes through a thermal high-pressure separator, it flashes into two parts, gas phase and liquid phase, and is heated under high pressure. After the liquid phase product of the separator is mixed with hydrogen, it enters the second hydrogenation reaction zone for pour point reduction and post-refining. The first hydrogenation reaction zone is filled with hydrotreating preparation I is RN-10, the upper part of the second hydrogenation reaction zone is filled with pour point depressant RDW-1, and the lower part is filled with hydrotreating preparation II is RN-10, with integral catalyst The ratio of the three parts of the catalyst is 50:40:10. These catalysts are all produced by Sinopec Changling Catalyst Plant, and their reaction conditions and results are listed in Table 1.

[0044...

Embodiment 2

[0049] The hydrorefining catalyst I, the pour point depressing catalyst, and the hydrorefining catalyst II used in this example are RN-10B, RDW-1, and RN-10B, all of which are produced by Changling Catalyst Factory. That is, RN-10B is loaded in the first reaction, RDW-1 is loaded in the upper part of the second reactor, and RN-10B is loaded in the lower part. Based on the volume of the whole catalyst, the ratio of the three parts of the catalyst is 50:45:5.

[0050] A diesel oil fraction is used as raw material B, and the method of the present invention is used to depress pour point and desulfurize it. First, the raw material B is subjected to full-cut hydrorefining in the first reactor, and the reaction product is flashed into two parts, gas phase and liquid phase, after the thermal high fraction, and the hot high fraction liquid product is mixed with hydrogen, and then enters the second The reactor performs pour point reduction and post-refining.

[0051] The reaction conditions...

Embodiment 3

[0057] The hydrorefining catalyst I, the pour point depressing catalyst, and the hydrorefining catalyst II used in this embodiment are RS-1000, RDW-1, and RS1000 in sequence, all of which are produced by Changling Catalyst Factory. That is, RS-1000 is loaded in the first reaction, RDW-1 is loaded in the upper part of the second reactor, and RS-1000 is loaded in the lower part. Based on the volume of the whole catalyst, the ratio of the three parts of the catalyst is 50:40:10.

[0058] A diesel oil fraction is used as raw material C, and the method disclosed in the present invention is used for pour point reduction and desulfurization. First, the raw material C is fully fractionated in the first hydrogenation reactor, and the reaction product is flashed into two parts, gas phase and liquid phase, after the thermal high fraction, and the hot high fraction liquid product is mixed with hydrogen, and then enters The second hydrogenation reactor performs pour point reduction and post-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com