Environment friendly energy-efficient heat conduction oil

An environmentally friendly, heat transfer oil technology, applied in the petroleum industry, heat exchange materials, base materials, etc., can solve the problems of affecting heat transfer efficiency, short service life, blocked pipelines, etc., and achieve high thermal conductivity and high viscosity index. , the effect of high specific heat capacity

Active Publication Date: 2013-08-07

GUANGXI UNIV

View PDF1 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when mineral oil is heated, it is easy to show various decomposition temperatures with the increase of temperature, which makes it easy to decompose and coke when it is used at high temperature for a long time, block the pipeline, affect the heat transfer efficiency, consume a lot of energy, and the indirect cost is expensive. There are many hidden dangers of accidents and short service life, which makes it difficult to meet the performance requirements of actual working conditions

In addition, with the continuous rise of international oil prices, the cost of using traditional mineral heat transfer oil will become higher and higher, and mineral heat transfer oil is difficult to decompose in nature, causing increasingly serious pollution to the natural environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

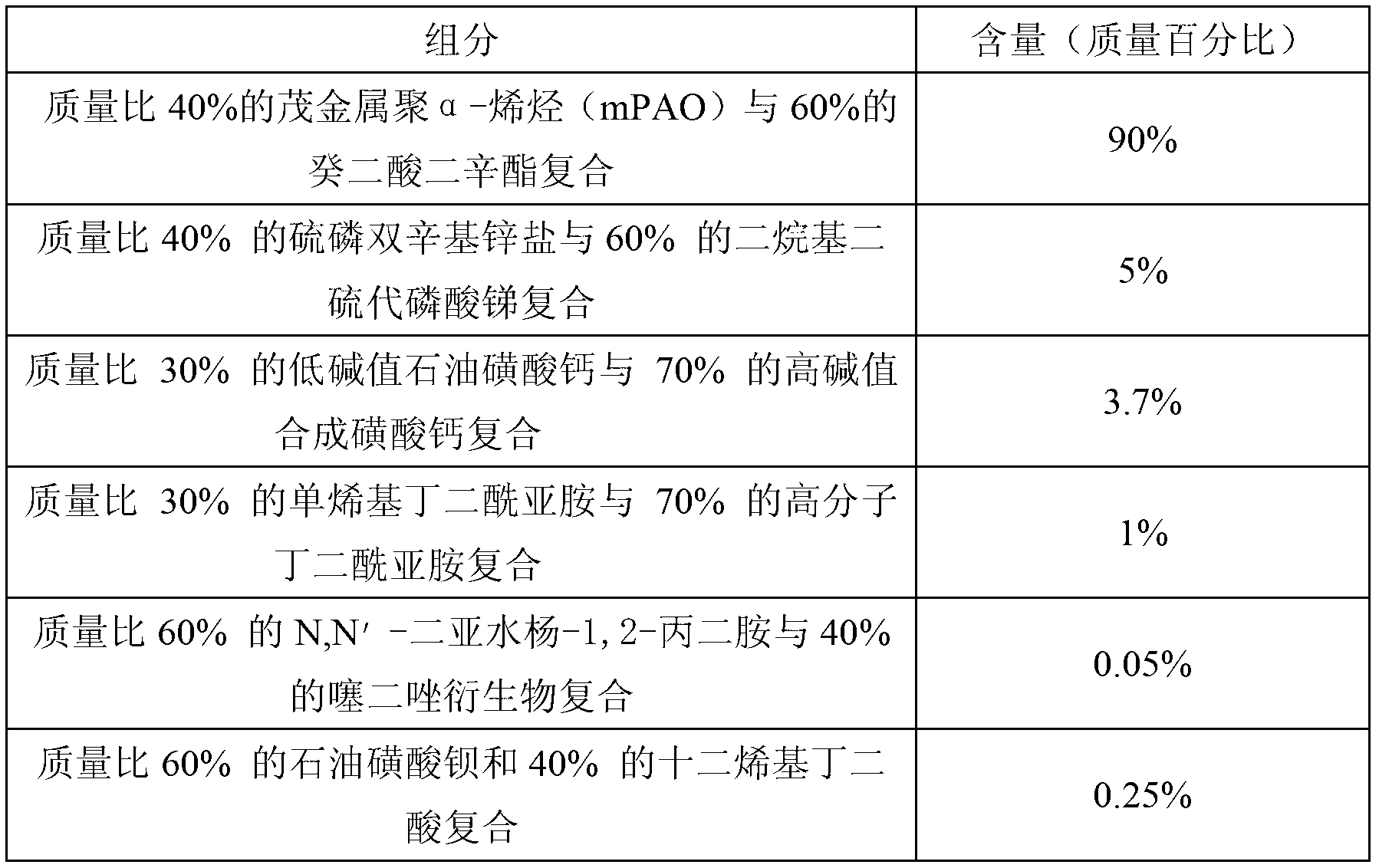

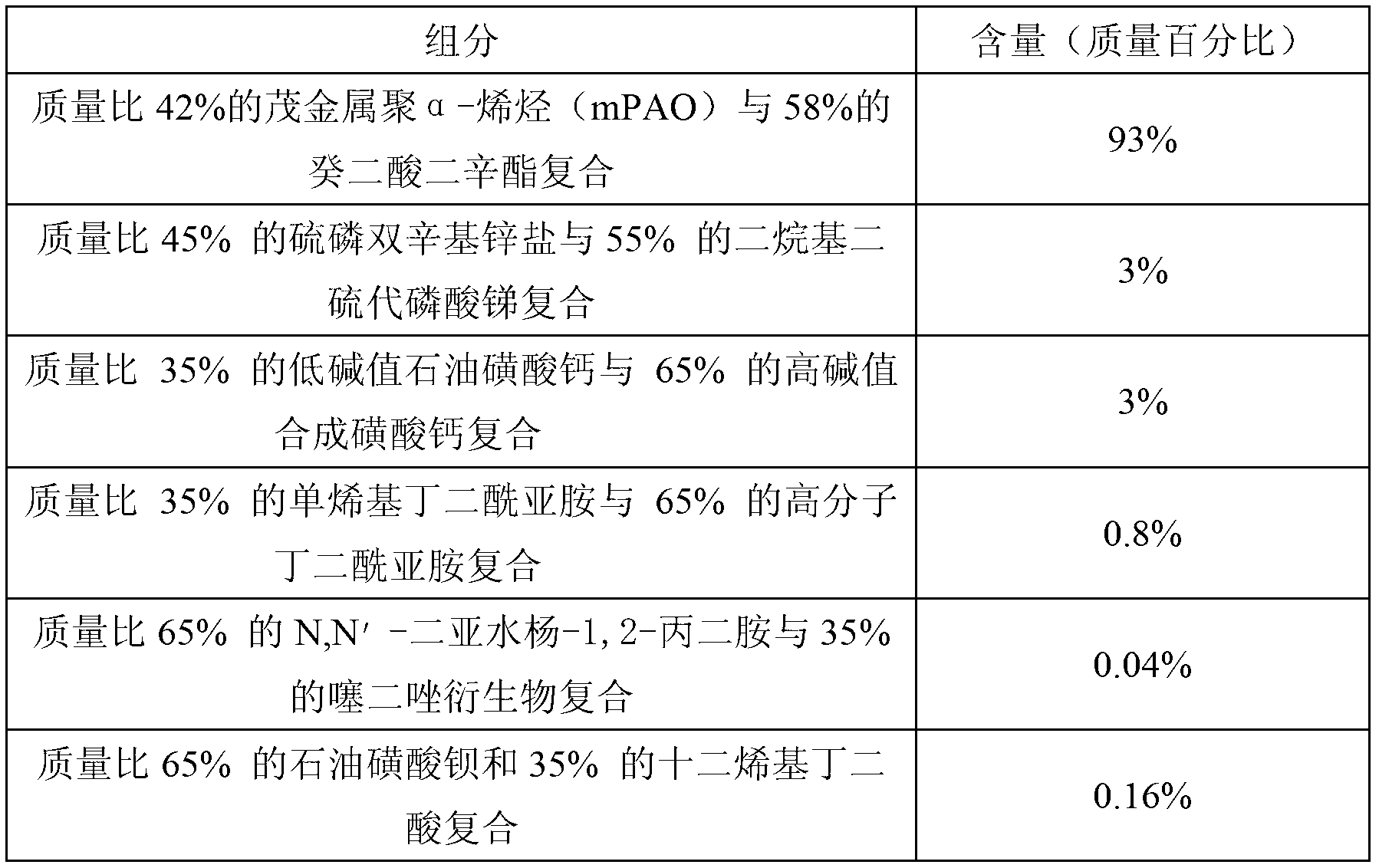

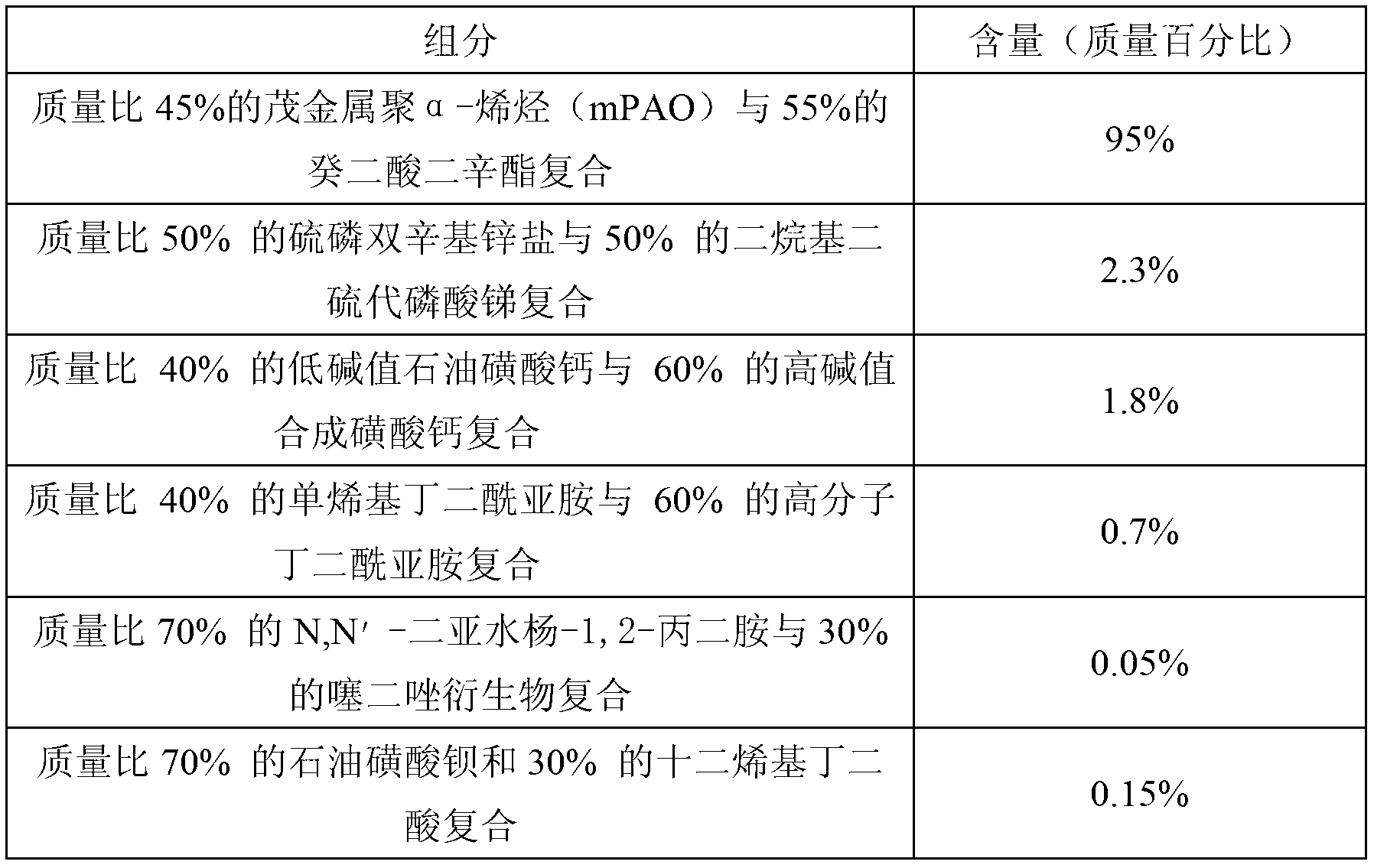

Embodiment 3

[0031] The following ingredients are blended according to mass percentage:

[0032]

[0033] The physical and chemical index of embodiment 3 is shown in Table 1:

[0034] Table 1 The physical and chemical indicators of environmentally friendly and energy-saving heat transfer oil

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The environment friendly energy-efficient heat conduction oil of the present invention is composed of 90-95% of base oil and 10-5% of other additives. The invention has advantages of low viscosity, low condensation point, high boiling point, low volatility, low acid value, free of smell, non-toxicity, high viscosity index, high flash point, high initial boiling point, high specific heat capacity, low temperature flow performance, material compatibility of system, high tepid stability, antioxidation stability, anti-corrosivity, antirust performance, peace and quiet dispersion performance, high heat conduction coefficient, biodegradability, and other performances. The index of each performance accords with the usage requirement, and can satisfy the technology requirements of the GB23971-2009 heat conduction oil with L-QB, L-QC, L-QD quality grade specifications and the performance requirements of those with temperature grades: 280, 300, 310, 320, 330, 340 and 350.

Description

technical field [0001] The invention belongs to heat conduction medium, in particular to an environment-friendly and energy-saving heat conduction oil. Background technique [0002] Heat transfer oil, also known as heat transfer fluid, has been widely used as a heat transfer medium in petroleum, petrochemical, coal chemical, electric power, metallurgy, textile printing and dyeing, non-ferrous metals, building materials, grain, oil chemistry, food processing, medicine, electronics, etc. industry. It has high heat transfer efficiency, non-toxic, high initial boiling point, good thermal stability, low viscosity, low freezing point, low water absorption, easy to adjust and control temperature, no corrosion to equipment, high cost performance, convenient recycling, Low investment and other advantages, and its use and consumption are also increasing. [0003] At present, domestic production is mostly based on mineral heat transfer oil. As we all know, mineral oil is obtained fr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K5/10C10M111/04C10M105/36

Inventor 黄福川粟满荣卢朝霞莫宇飞梁景唐兴中蓝明新李宏君肖友程李胜梁慧田宗义唐彩珍赵钟兴唐丹葵刘琨

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com