Method for producing second-generation biodiesel by hydrogenation production of illegal cooking oil

A biodiesel and waste oil technology, which is applied in the fields of biofuel, fatty acid hydrogenation, chemical instruments and methods, etc., to achieve the effects of reducing hydrogen consumption, improving selectivity and high cetane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 120mL impregnation solution containing 75.5 grams of nickel hypophosphite, and impregnate an equal volume in 100 grams of macroporous SiO 2 The carrier (Qingdao Ocean Chemical Co., Ltd.) was placed at room temperature for 2 hours, and then placed in a vacuum oven at 60°C for 4 hours. The obtained sample was placed in a tube furnace and treated with nitrogen at 250°C for 3 hours to obtain the catalyst Ni 2 P / SiO 2 (C1, active component NiO: 16%).

[0022] Activity Evaluation of Catalyst C1

[0023] Catalyst hydrorefining activity evaluation was carried out on Tuochuan 100ml small-scale continuous hydrogenation reaction device. The reactor was a 24×800mm stainless steel tube, and the loading capacity of the catalyst was 100ml. The pretreated waste oil used for the evaluation was filled with 100ml of catalyst C1. In the hydrogenation reactor, connect the hydrogen, adjust the reaction pressure to 4.0MPa, the hydrogen flow rate is 75L / h, and the space velocity is ...

Embodiment 2

[0025] Get 73.9 grams of nickel nitrate [Ni(NO 3 ) 2 .6H 2 O] Completely dissolve in water to configure 120 immersion liquid, impregnate equal volume in 100 grams of macroporous SiO 2 The carrier was placed at room temperature for 2 hours, then placed in a forced air oven at 60 °C overnight, and then calcined in a muffle furnace at 500 °C for 4 h, and the calcined solid was cooled to room temperature and transferred to a tube-type quartz furnace, and then transferred Continuously feed hydrogen (H2) into a type quartz furnace, and gradually raise the temperature of the furnace to 450°C and keep it at 450°C for 4h to obtain the catalyst Ni / SiO 2 (C2, active component NiO: 16%),

[0026] The evaluation device, loading amount, raw materials, and experimental conditions used for catalyst C2 activity evaluation are exactly the same as those in Example 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0028] Catalyst C3 is a CoMoS catalyst commonly used in industry. The evaluation device, loading amount, raw materials, and experimental conditions used for the activity evaluation are exactly the same as those in Example 1. The evaluation results are shown in Table 2.

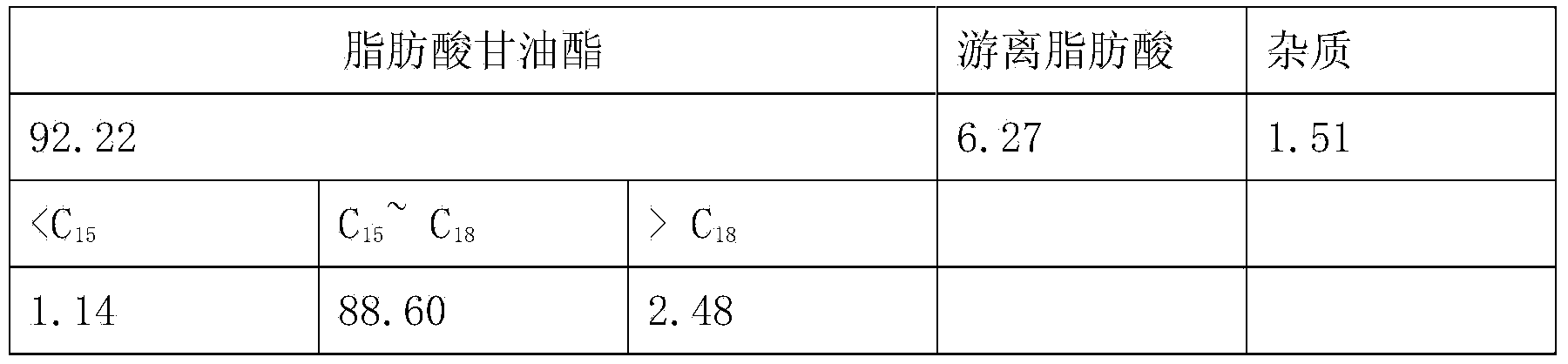

[0029] The main components of table 1 waste oil (mass percentage wt%)

[0030]

[0031] Table 2 Distribution of waste oil hydrogenation products on different catalysts

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com