High-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor

A wax removal, prevention and environmental protection technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting output, limited scope of popularization and application, high flammability, explosion and toxicity, etc. Fast speed, overcoming the singularity of effect, and good effect of condensed oil hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 5.4g compound emulsifier preparation: weigh 3.4g triethanolamine sodium, 2g C 18 Mixture of unsaturated olefinic acids;

[0013] Main agent A agent system preparation: Weigh 2g alkylnaphthalene T801, 50g xylene, 5.4g compound emulsifier, 13g ethanol, 29.6g water and mix and stir;

[0014] Preparation of adjuvant B agent system: Weigh 10g of hydrochloric acid (31%) and mix with 40g of water.

Embodiment 2

[0016] 3g compound emulsifier preparation: weigh 1.9g sodium oleate, 1.1g C 18 Mixture of unsaturated olefinic acids;

[0017] Main agent A agent system preparation: Weigh 1g alkylnaphthalene T801, 51g xylene, 3g emulsifier, 15g methanol, 30g water and mix and stir;

[0018] Preparation of auxiliary agent B system: weigh 10g of hydrochloric acid (31%) and mix with 40g of water

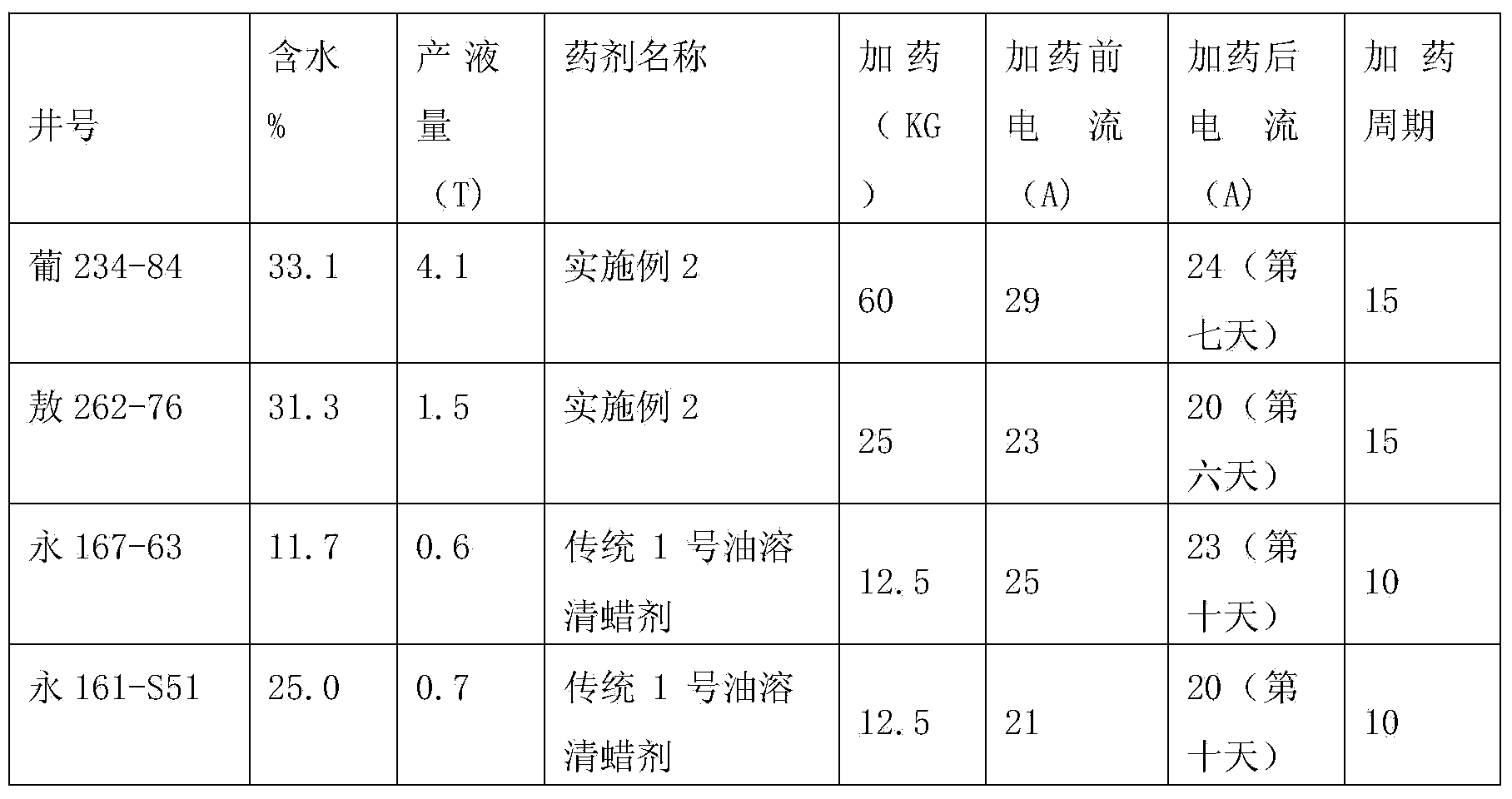

[0019] The compound antifreeze emulsion paraffin remover of this formula is compared with the traditional oil-soluble solvent paraffin remover in field application of the No. 7 oil production plant in Daqing Oilfield, as shown in Table 1:

[0020] It can be seen from Table 1 that, with the same percentage of chemicals added, the compound antifreeze emulsion wax remover is obviously faster than the traditional oil-soluble wax remover, and the action period is longer.

[0021] Table 1

[0022]

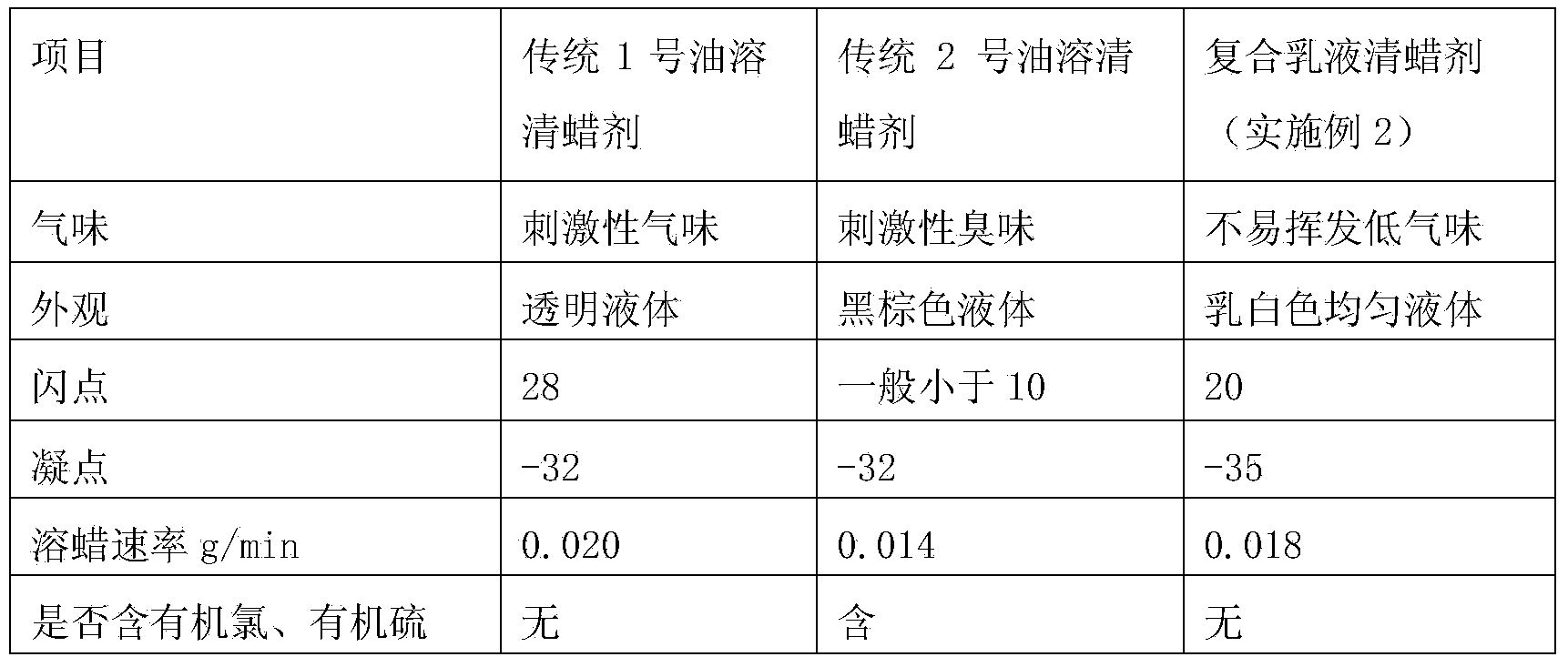

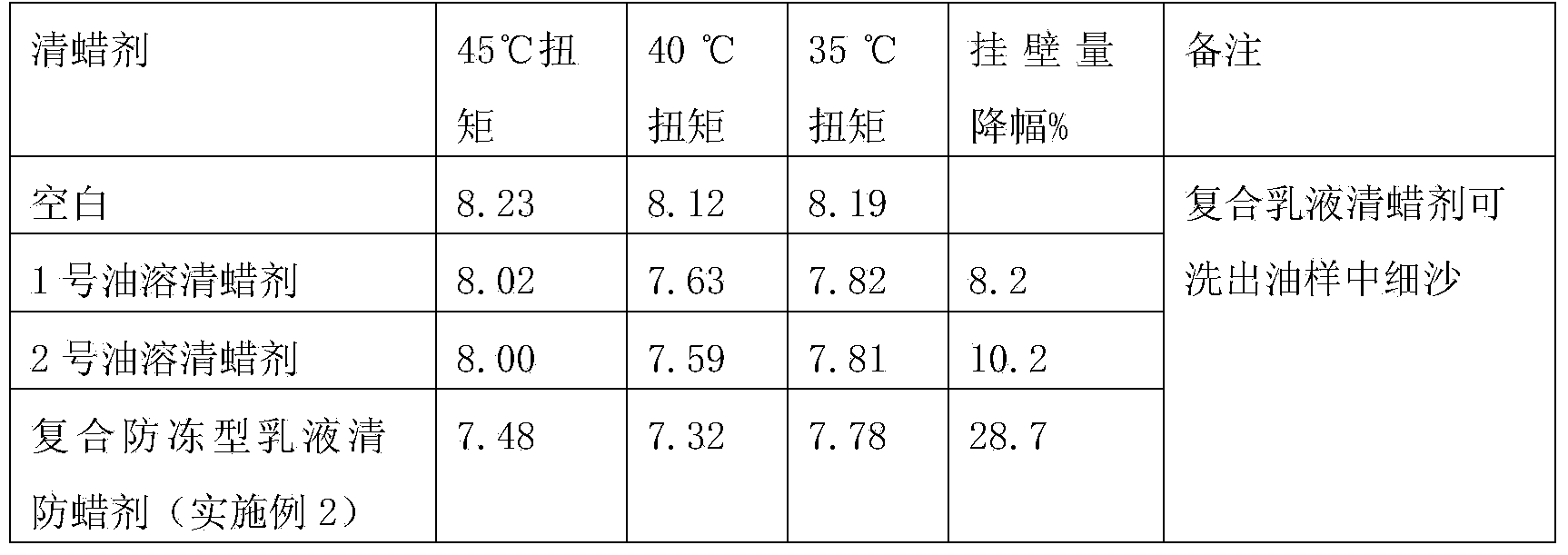

[0023] Indoor evaluation effect of the composite antifreeze emulsion wax clearing agent:

[0024] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com