High value utilization method of gutter oil

A waste oil, high-value technology, applied in chemical instruments and methods, processing hydrocarbon oil, petroleum industry, etc., can solve problems such as high cost, complex reaction process, calorific value, viscosity, corrosiveness gap, etc., to improve the strength. , The effect of high catalytic cracking conversion rate and high liquid phase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

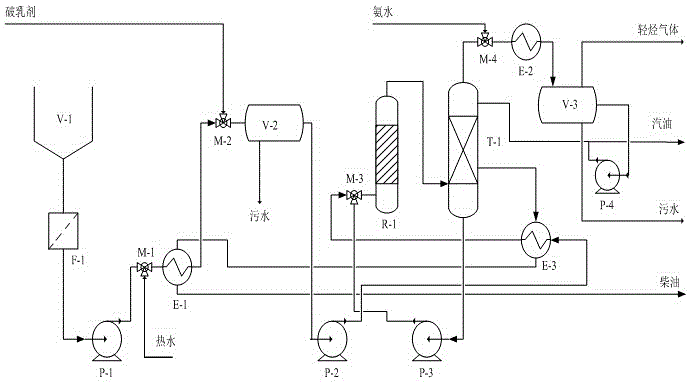

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: preparation catalyst and modified attapulgite

[0045] (1) Weigh 50 g of rare earth materials, Re=La, Ce, Pr, Nd, Sm, Eu, Gd rare earth metal oxalate or nitrate, dissolve it in 100 g of water to form a paste, and stir it gradually Add concentrated nitric acid with a mass fraction of 65% dropwise until it is completely dissolved, then add 5 g of citric acid solid powder to dissolve, and slowly evaporate into a sol at 70°C;

[0046] (2) Weigh the molecular sieve and add it into the sol according to the ratio of the amount of rare earth to the total weight of the molecular sieve as 2%, stir evenly, become a gel after drying, heat up to 550°C and roast for 2 hours to obtain a rare earth modified molecular sieve;

[0047] (3) Prepare 100 ml of sodium hexametaphosphate dispersant aqueous solution with a mass concentration of 1.0%, and add commercially available attapulgite at a solid-to-liquid ratio of 1:15, stir at a high speed for 0.5 h, and then stand for 1 h...

Embodiment 2

[0050] Embodiment 2: preparation catalyst and modified attapulgite

[0051] (1) Weigh 50 g of rare earth materials, Re=La, Ce, Pr, Nd, Sm, Eu, Gd rare earth metal oxalate or nitrate, dissolve it in 100 g of water to form a paste, and stir it gradually Add concentrated nitric acid with a mass fraction of 65% dropwise until it is completely dissolved, then add 5 g of citric acid solid powder to dissolve, and slowly evaporate into a sol at 80°C;

[0052] (2) Weigh the molecular sieve and add it into the sol according to the ratio of the amount of rare earth to the total weight of the molecular sieve as 4%, stir evenly, become a gel after drying, and heat up to 600°C for 2 hours to obtain the rare earth modified molecular sieve;

[0053] (3) Prepare 100 ml of sodium hexametaphosphate dispersant aqueous solution with a mass concentration of 1.1%, add commercially available attapulgite at a solid-to-liquid ratio of 1:22.5, stir at high speed for 0.5 h, and then stand still for 1.5 h...

Embodiment 3

[0056] Embodiment 3: preparation catalyst and modified attapulgite

[0057] (1) Weigh 50 g of rare earth materials, Re=La, Ce, Pr, Nd, Sm, Eu, Gd rare earth metal oxalate or nitrate, dissolve it in 100 g of water to form a paste, and stir it gradually Add concentrated nitric acid with a mass fraction of 65% dropwise until it is completely dissolved, then add 5 g of citric acid solid powder to dissolve, and slowly evaporate into a sol at 90°C;

[0058] (2) Weigh the molecular sieve and add it into the sol according to the ratio of the amount of rare earth to the total weight of the molecular sieve as 6%, stir evenly, become a gel after drying, heat up to 650°C and roast for 2 hours to obtain a rare earth modified molecular sieve;

[0059] (3) Prepare 100 ml of sodium hexametaphosphate dispersant aqueous solution with a mass concentration of 1.2%, add commercially available attapulgite at a solid-to-liquid ratio of 1:30, stir at high speed for 0.5 h, and then let stand for 2 h t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com