Hydroisomerization/cracking catalyst, and preparation method and application thereof

A cracking catalyst and isomerization cracking technology, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as failure to achieve results, and achieve low freezing point, good pour point depressing effect, diesel oil yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

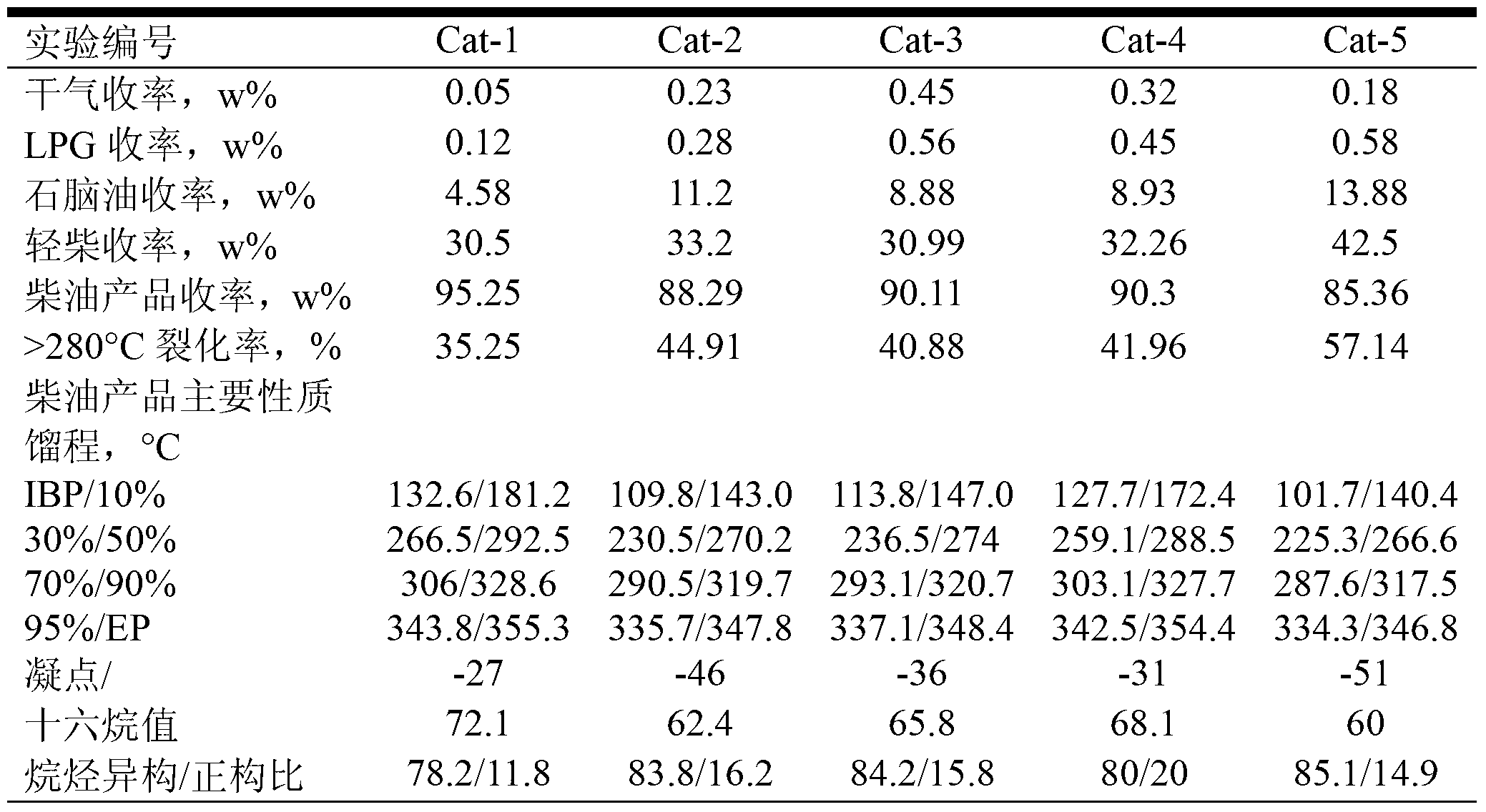

[0038] Embodiment 1, preparation of hydroisomerization / cracking catalyst Cat-1

[0039](1) Weigh the finely ground ZSM-22 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 80, and the specific surface area is 535.6m 2 / g, infrared acidity is 0.26mmol / g, Na 2 O content is 0.02%, pore volume is 0.35mL / g) 4.6g (dry basis) and amorphous silicon aluminum (SiO 2 The mass content is 25%, the pore volume is 1.38ml / g, and the specific surface area is 535.6m 2 / g, the pore volume of the pores between 3 and 15nm accounts for 75% of the total pore volume, and the infrared acidity is 0.68mmol / g) 87.4g (dry basis) are mixed, placed in a kneader and mixed for 30min, and diluted with 3% Prepared with nitric acid solution, kneaded to a paste, extruded into a cylindrical shape, the diameter of the catalyst is 1.4mm. Dry it in an oven at 120°C for 4h, bake it at 600°C for 4h and cool to room temperature to obtain the acidic isomerization cracking carrier.

[0040] (2) Spray 17.55g of co...

Embodiment 2

[0044] Embodiment 2, preparation of hydroisomerization / cracking catalyst Cat-2

[0045] (1) Weigh the finely ground ZSM-22 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 92, and the specific surface area is 486.9m 2 / g, infrared acidity is 0.18mmol / g, Na 2 O content is 0.01%, pore volume is 0.29mL / g) 10.8g (dry basis) and amorphous silicon aluminum (SiO 2 The mass content is 35%, the pore volume is 0.98ml / g, and the specific surface area is 490.3m 2 / g, the pore volume of pores between 3 and 15nm accounts for 69% of the total pore volume, and the infrared acidity is 0.57mmol / g) mixed with 61.2g (dry basis), placed in a kneader and mixed for 15min. Prepare it with 3wt% acetic acid solution, knead it until it becomes a paste, extrude it into a clover shape, and the diameter of the catalyst is 1.5mm. Dry it in an oven at 130°C for 4h, roast at 550°C for 4h and cool to room temperature to obtain the acidic isomerization cracking carrier.

[0046] (2) Spray the aqueous ...

Embodiment 3

[0050] Embodiment 3, preparation of hydroisomerization / cracking catalyst Cat-3

[0051] (1) Weigh the finely ground ZSM-22 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 111, and the specific surface area is 396.8m 2 / g, infrared acidity is 0.13mmol / g, Na 2 O content is 0.03%, pore volume is 0.26mL / g) 18.5g (dry basis) and amorphous silicon aluminum (SiO 2 The mass content is 50%, the pore volume is 0.58ml / g, and the specific surface area is 384.5m 2 / g, the pore volume of pores between 3 and 15nm accounts for 64% of the total pore volume, and the infrared acidity is 0.50mmol / g) 55.5g (dry basis) mixed, placed in a kneader and mixed for 40min, 5wt% dilute nitric acid The aqueous solution is mixed and kneaded to a paste, extruded into a four-leaf clover shape, and the diameter of the catalyst is 1.7mm. Dry it in an oven at 120°C for 5h, roast at 550°C for 6h and cool to room temperature to obtain the acidic isomerization cracking carrier.

[0052] (2) 16.09g of nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Infrared acidity | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com