Slime reducing agent suitable for heavy oil wells with different mineralization and application

A slime reducing agent and salinity technology, applied in the direction of microorganism-based methods, bacteria, wellbore/well components, etc., can solve the problems of inability to guarantee reproduction, metabolic ability, reproduction, and metabolic ability decline, and the difficulty of microorganisms in surviving , to achieve the effect of environmental protection technology selection, reducing the viscosity of heavy oil, increasing production and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

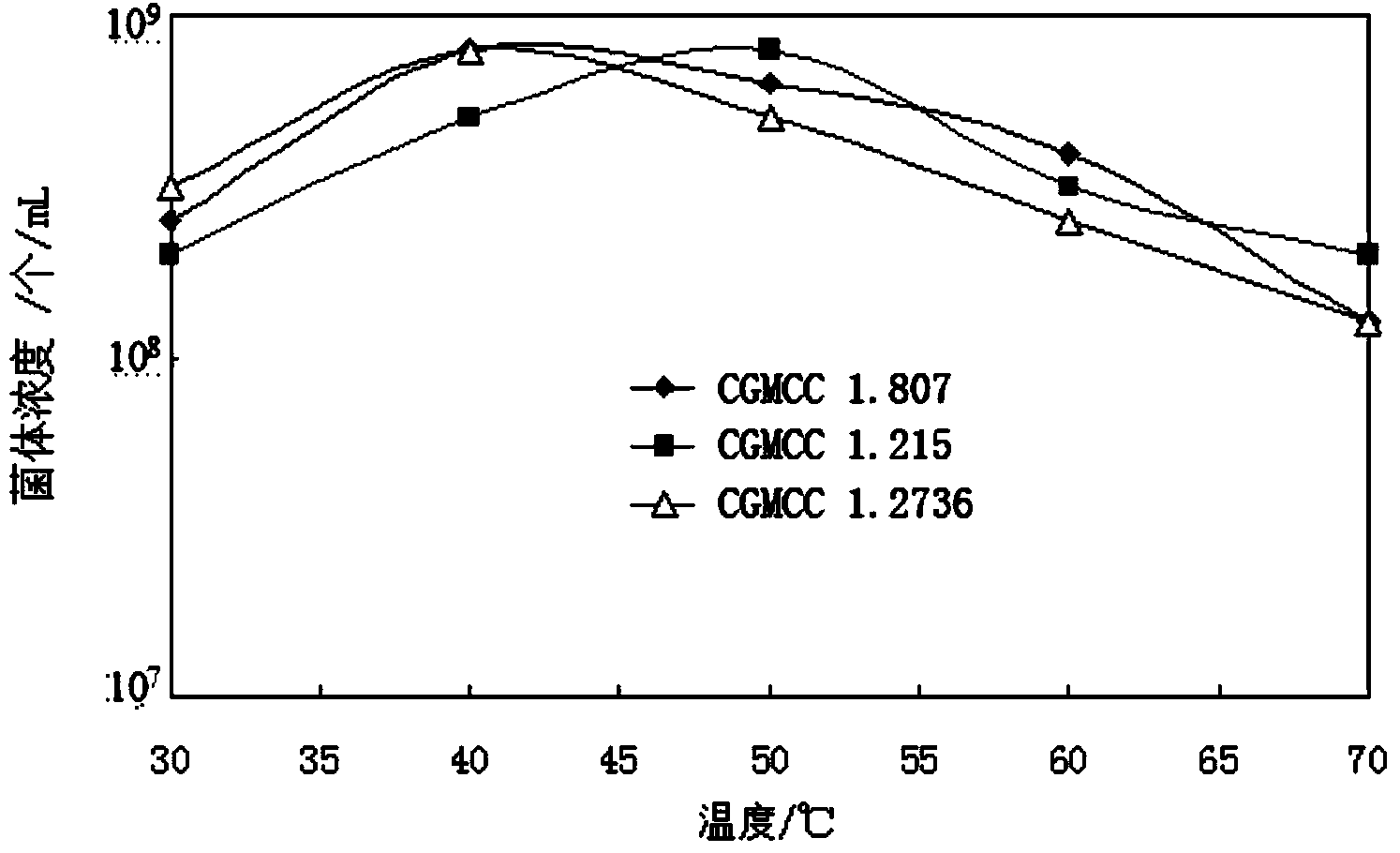

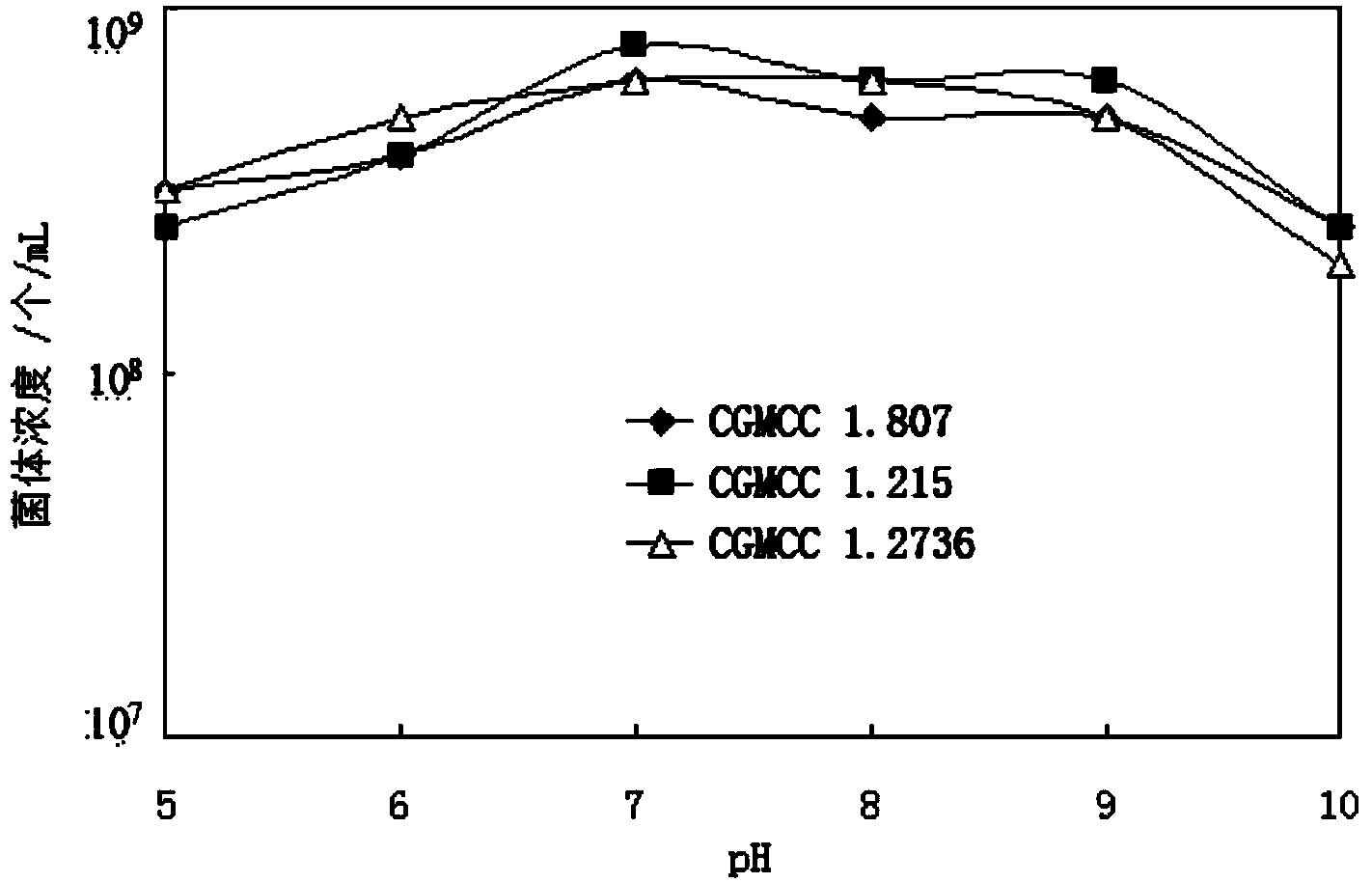

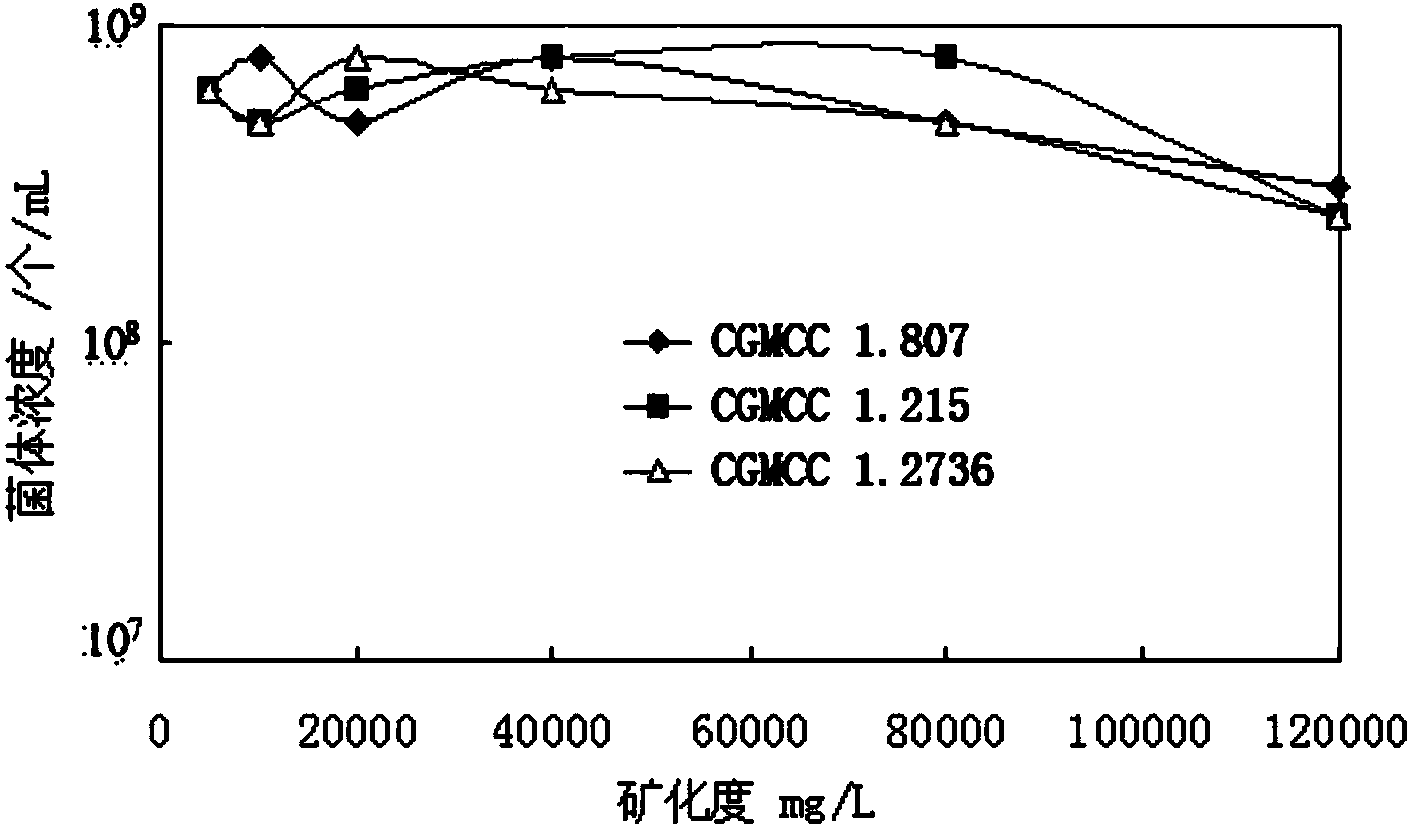

[0038] In this example, the viscosity-reducing bacteria agent suitable for heavy oil wells with different salinities is composed of Bacillus licheniformis (CGMCC 1.807), Bacillus subtilis (CGMCC 1.215) and Bacillus thuringiensis (CGMCC 1.2736), and all three strains are purchased From the China General Microorganism Culture Collection Management Center (CGMCC), the bacterial agent is a solid dry powder, and the three bacteria are stored separately, all using skim milk as a protective agent and carrier, and the mass ratio of the three bacterial dry powders is 1:1:1.

[0039] This embodiment is suitable for the application of viscosities reducing agents in heavy oil wells with different salinities in oil recovery, including the following steps:

[0040] (1) Activate each strain separately until the cell concentration of each strain reaches 1.5~5.7×10 8 Each bacterial solution (2L) was mixed in equal volumes, and then the compound bacterial solution was added to the fermentation ...

Embodiment 2

[0046] In this example, the viscosity-reducing bacteria agent suitable for heavy oil wells with different salinities is composed of Bacillus licheniformis (CGMCC1.807), Bacillus subtilis (CGMCC1.215) and Bacillus thuringiensis (CGMCC1.2736), three strains The bacteria were purchased from the China General Microorganism Culture Collection Management Center (CGMCC). The bacteria agent was in liquid state and stored separately. 8 individual / mL.

[0047] This embodiment is suitable for the application of viscosities reducing agents in heavy oil wells with different salinities in oil recovery, including the following steps:

[0048] (1) Take the equal volumes of the various bacterial strains and mix them, transfer the compound bacterial liquid to the fermenter, add the fermentation medium at a volume ratio of 1:5, ferment and cultivate at 35°C for 72 hours, and control the pH value at 6~ 8. There is no need to pass oxygen or air during the fermentation process. After the fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com