Catalyst used for hydrogenation ring opening reaction of polycyclic aromatic hydrocarbon, and preparation method and application thereof

A hydrogenation ring-opening and condensed-ring aromatics technology, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as increasing the cetane number without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

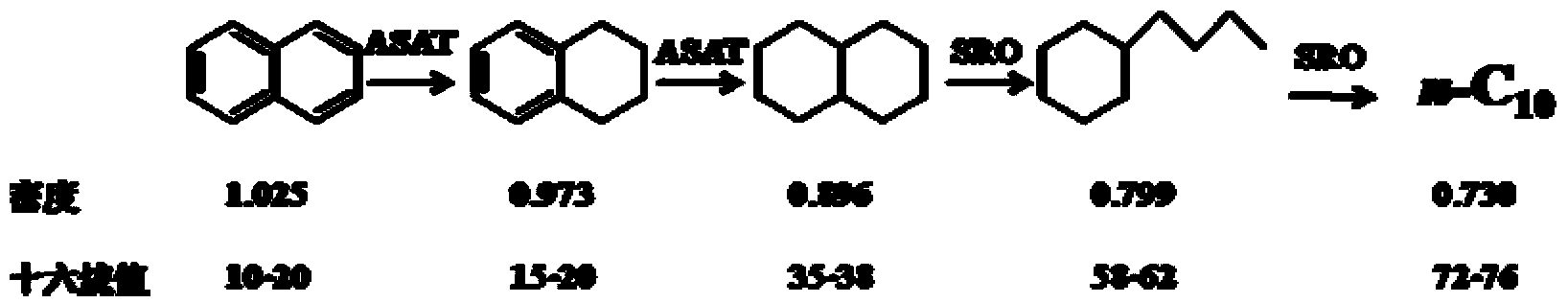

Problems solved by technology

Method used

Image

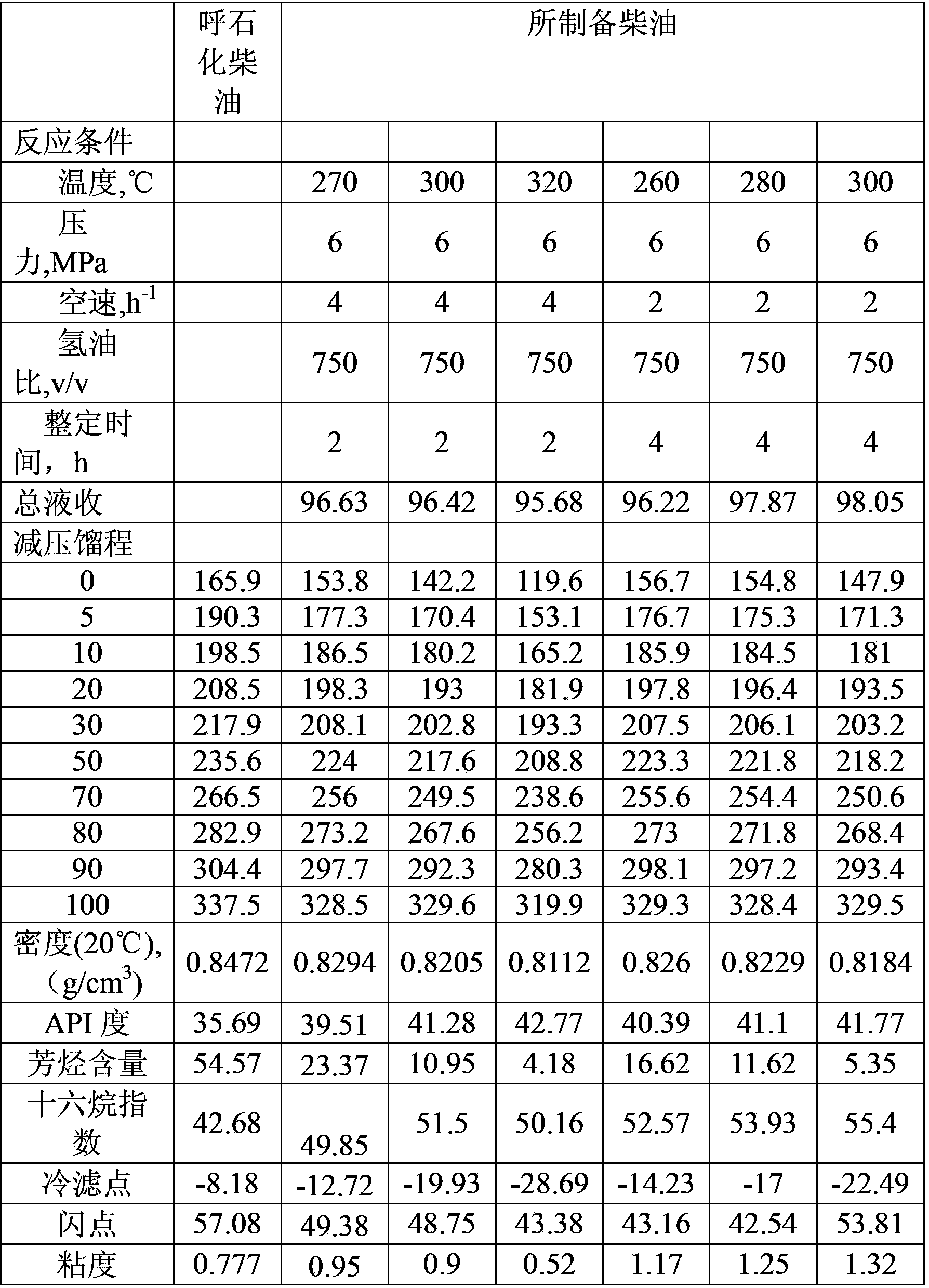

Examples

Embodiment 1

[0028] Weigh 100 g of Beta zeolite molecular sieve raw powder with a silicon-aluminum ratio of 30 and put it into a three-necked flask, then add 1000 ml of 0.4 mol / L ammonium nitrate, and exchange at 80° C. for 2 hours. After the exchange, it is dried, and then placed in a muffle furnace for calcination at 550° C. for 4 hours to obtain an acidic H-Beta zeolite molecular sieve.

[0029] Weigh 10g of acidic H-Beta molecular sieve and 3g of alumina to form it, dry it after forming, and then bake at 500°C for 4h. Using the equal-volume impregnation method, chloroplatinic acid was spray-impregnated on the calcined shaped catalyst carrier, and the Pt loading was 0.5wt%. The metal-supported molecular sieve catalyst was calcined at 500° C. for 5 hours. The calcined catalyst was reduced in a hydrogen atmosphere at a reduction temperature of 500°C for 4 hours, and the obtained catalyst was ready for use.

Embodiment 2

[0031] Preparation of acidic H-Beta zeolite molecular sieve modified by nitric acid. Weigh 30 g of the acidic H-Beta zeolite molecular sieve prepared in Example 1 and put it into a three-necked flask, then add 200 ml of 1.0 mol / L nitric acid, and exchange at 80° C. for two hours. After the exchange, it was dried, and then placed in a muffle furnace for calcination at 550° C. for 4 hours to obtain a nitric acid-modified H-Beta zeolite molecular sieve.

Embodiment 3

[0033] Citric acid modified acidic H-Beta zeolite molecular sieve. Weigh 20 g of the acidic H-Beta zeolite molecular sieve prepared in Example 1 and put it into a three-necked flask, then add 200 ml of 1.5 mol / L citric acid, and exchange at 80° C. for two hours. After the exchange, it was dried, and then put into a muffle furnace for calcination at 500° C. for 4 hours to obtain a citric acid-modified H-Beta zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com