Photovoltaic and photo-thermal integrated building material photovoltaic module

A photovoltaic module and photothermal technology, applied in the field of solar cells, can solve problems such as the decline of photoelectric conversion efficiency, and achieve the effects of easy promotion, no risk of explosion, and low metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

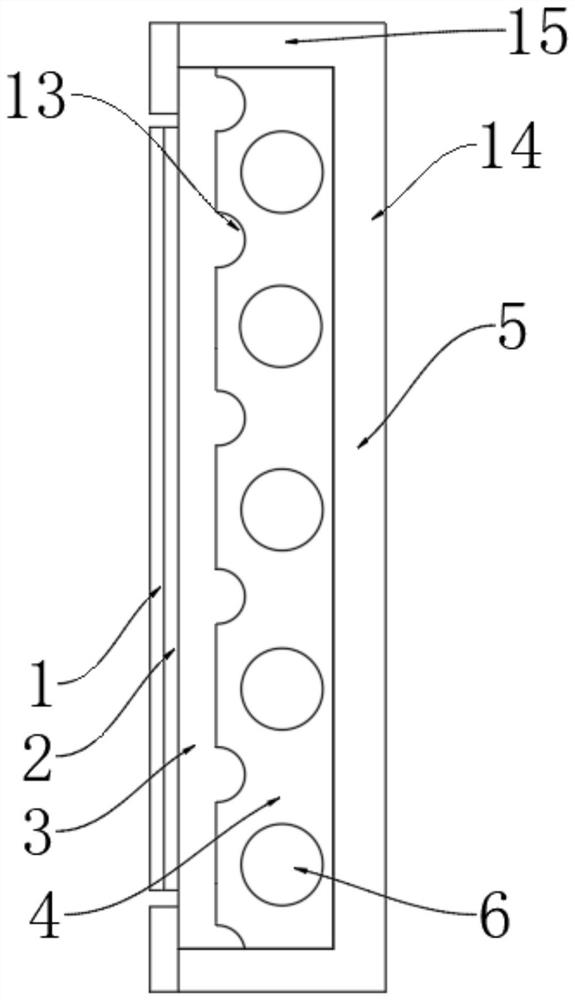

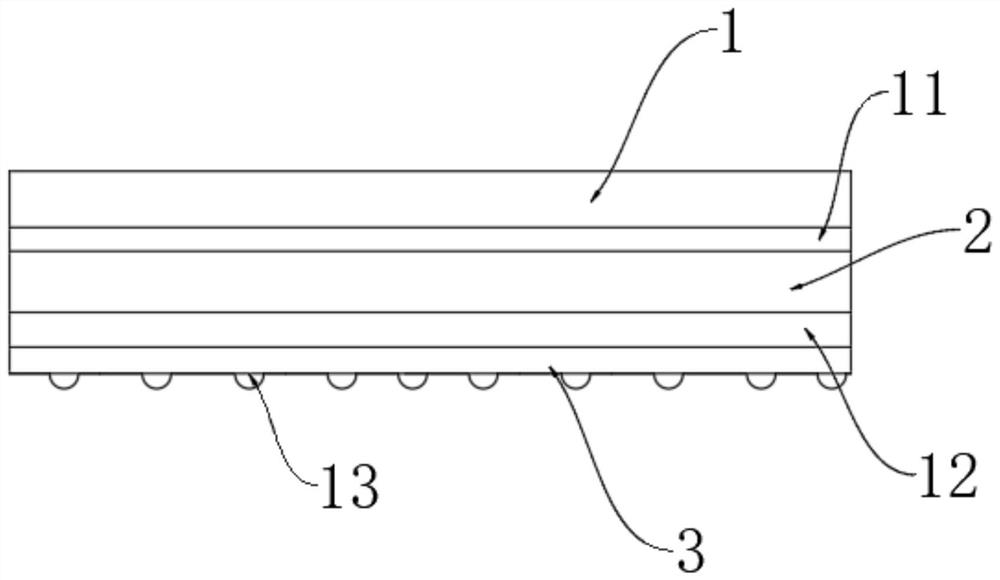

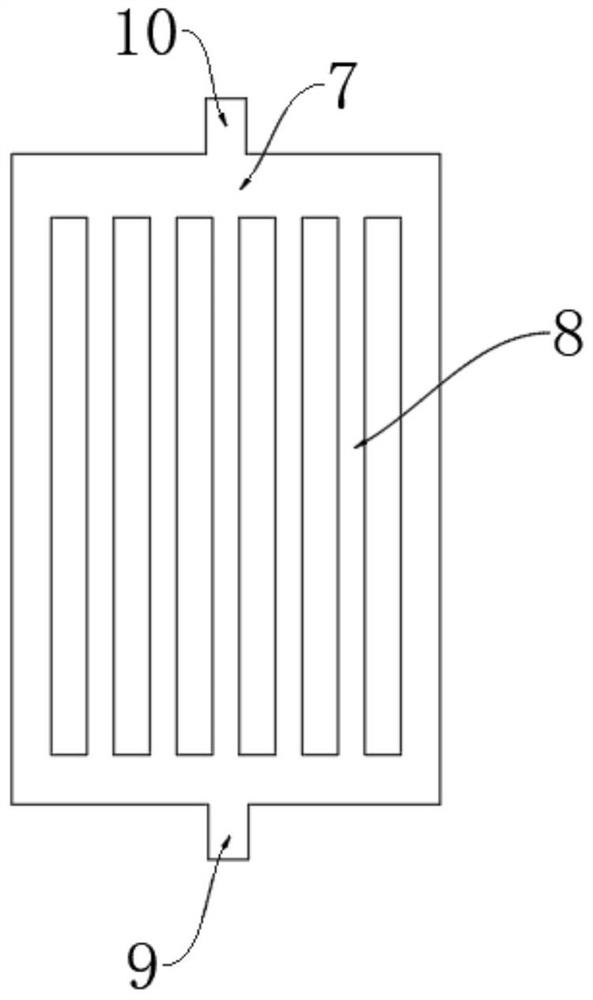

[0051] Embodiment one: according to image 3 As shown, the two liquid collecting pipes are respectively connected with the upper and lower ends of the branch pipe 8, the top of the middle section of the upper liquid collecting pipe is provided with a flow channel inlet 10, the bottom of the middle section of the liquid collecting pipe at the lower part is provided with a flow channel outlet 9, and the branch pipe 8 is Several dispensing tubes are arranged side by side, and the length of several dispensing tubes is the same; and the distance between two adjacent dispensing tubes is the same, and the diameter of both ends of each dispensing tube is larger than the diameter of the middle part of the dispensing tube . The liquid collecting pipe is a horizontal flow channel and the liquid distribution pipe is a vertical flow channel; the liquid enters the liquid collecting pipe from the flow channel inlet 10, and then flows into each liquid distribution pipe evenly

[0052] Furthe...

Embodiment 2

[0053] Embodiment two: according to Figure 5 As shown, the two liquid collecting pipes are respectively connected with the upper and lower ends of the branch pipe 8, one end of the upper liquid collecting pipe is provided with a flow channel inlet 10, and one end of the lower liquid collecting pipe is provided with a flow channel outlet 9 and a flow channel inlet 10 Arranged on the same side as the outlet 9 of the flow channel; the branch pipe 8 is formed by arranging a number of liquid pipes side by side, and the lengths of the several liquid pipes are the same; and the distance between two adjacent liquid pipes is the same, the The diameter gradually decreases in the same horizontal direction. The dispensing tubes near the channel outlet 9 and the channel inlet 10 are the smallest diameter dispensing tubes. The liquid collection pipe is a horizontal channel and the liquid distribution pipe is a longitudinal flow channel; the liquid enters the liquid collection pipe from th...

Embodiment 3

[0054] Embodiment three, according to Figure 4 As shown, the two liquid collecting pipes are respectively connected with the upper and lower ends of the branch pipe 8, one end of the upper liquid collecting pipe is provided with a flow channel inlet 10, and the other end of the lower liquid collecting pipe is provided with a flow channel outlet 9, and the flow channel outlet 9 is arranged away from the inlet 10 of the runner. The branch pipe 8 is formed by arranging several liquid pipes side by side, and the lengths of the several liquid pipes are the same; and the distance and diameter between two adjacent liquid pipes are the same. The liquid collection pipe is a horizontal channel and the liquid distribution pipe is a longitudinal flow channel; the liquid enters the liquid collection pipe from the inlet 10 of the flow channel, and the liquid distribution pipes are parallel to each other, and the distance between two adjacent liquid distribution pipes same. This structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com