Atmospheric pressure hot blast stove

A technology of hot blast stove and normal pressure, which is applied in air heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of no flue gas heat energy, low thermal conductivity, and recovery, so as to reduce production costs and improve heat transfer Efficiency, the effect of lowering the discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

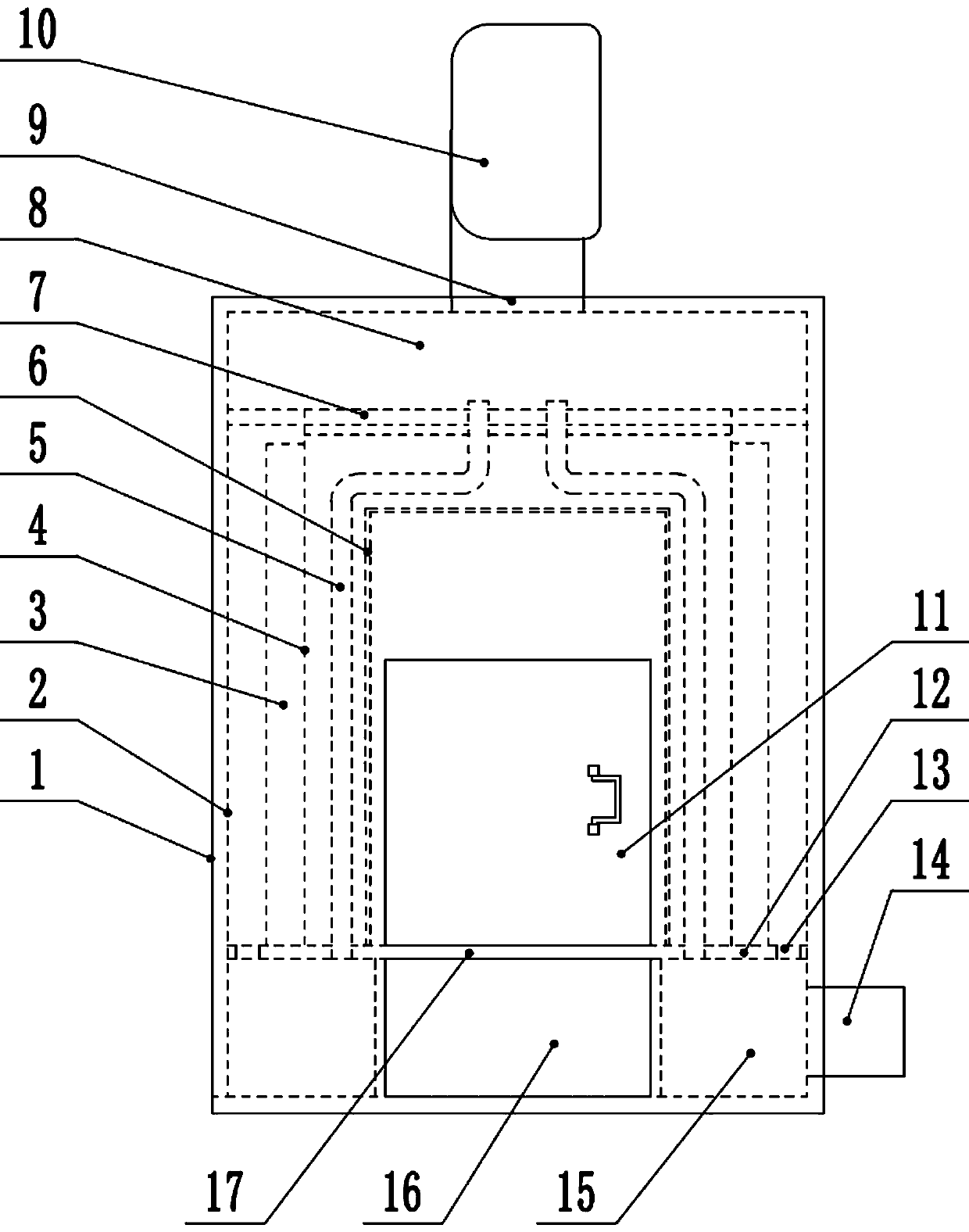

[0029] A kind of normal pressure hot blast stove, comprises furnace shell 1 and furnace wall 4, described furnace shell 1 inner wall is provided with insulation layer 2, the front of furnace shell 1 is provided with furnace door 11; Furnace wall 4 is arranged in furnace shell 1, The furnace wall 4 on the side away from the furnace door 11 is provided with a smoke exhaust port, the bottom of the furnace wall 4 is provided with a grate 17, the lower part of the grate 17 is provided with an ash collection chamber 16, and the lower part of the furnace shell 1 is provided with a hot air chamber interlayer 12, The hot air bin interlayer 12 separates the two sides and the rear of the ash collecting chamber 16 into interconnected hot air bins 15; the hot air bin 15 is provided with a hot air outlet 14, and the hot air discharged from the hot air outlet 14 is transported to the place where hot air is needed through the hot air delivery pipe; The top of the furnace wall 4 is provided wit...

Embodiment 2

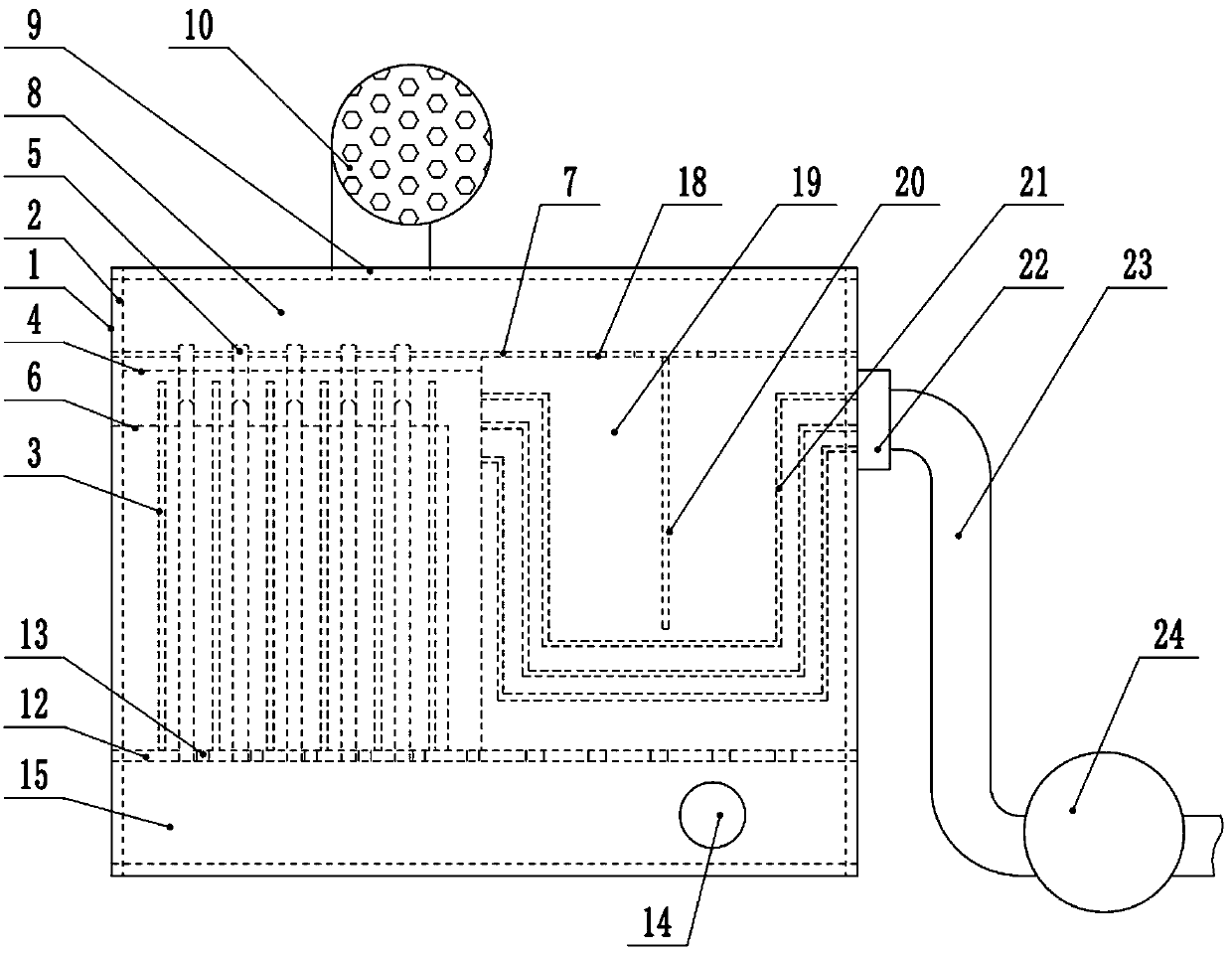

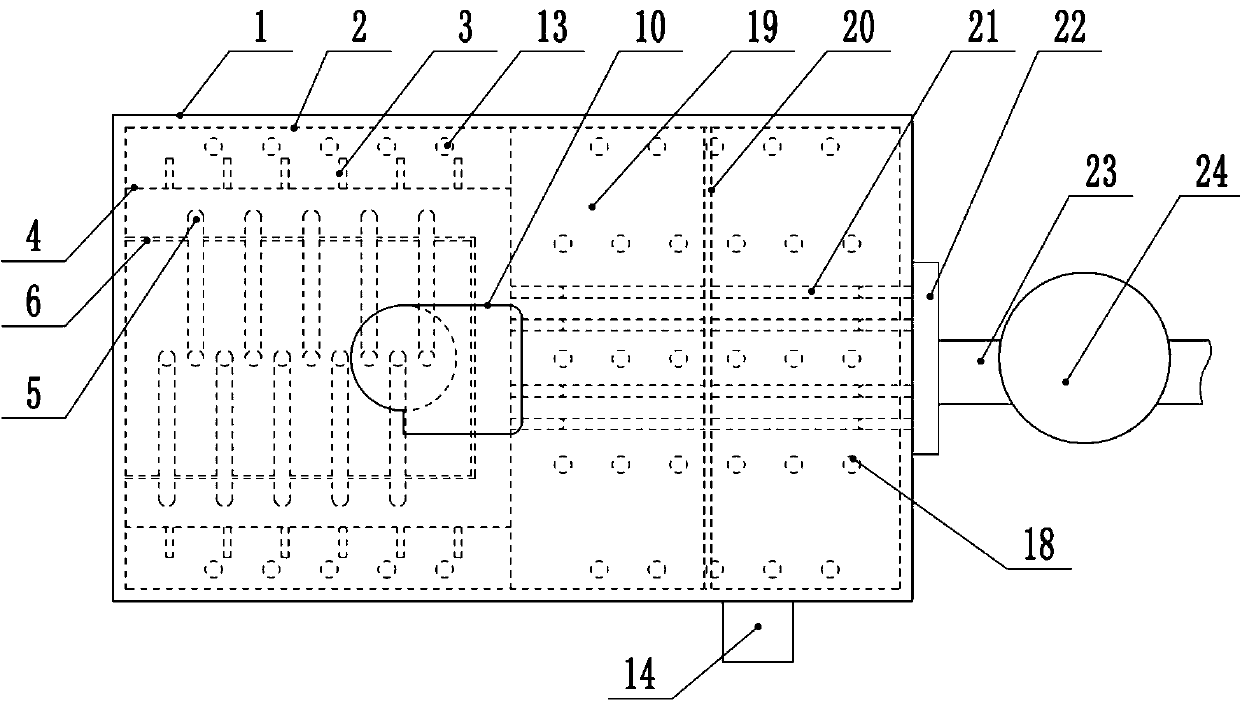

[0031] A kind of normal pressure hot blast stove, comprises furnace shell 1 and furnace wall 4, described furnace shell 1 inner wall is provided with insulation layer 2, the front of furnace shell 1 is provided with furnace door 11; Furnace wall 4 is arranged in furnace shell 1, The furnace wall 4 on the side away from the furnace door 11 is provided with a smoke exhaust port, the bottom of the furnace wall 4 is provided with a grate 17, the lower part of the grate 17 is provided with an ash collection chamber 16, and the lower part of the furnace shell 1 is provided with a hot air chamber interlayer 12, The hot air bin interlayer 12 separates the two sides and the rear of the ash collecting chamber 16 into interconnected hot air bins 15; the hot air bin 15 is provided with a hot air outlet 14, and the hot air discharged from the hot air outlet 14 is transported to the place where hot air is needed through the hot air delivery pipe; The top of the furnace wall 4 is provided wit...

Embodiment 3

[0034] A kind of normal pressure hot blast stove, comprises furnace shell 1 and furnace wall 4, described furnace shell 1 inner wall is provided with insulation layer 2, the front of furnace shell 1 is provided with furnace door 11; Furnace wall 4 is arranged in furnace shell 1, The furnace wall 4 on the side away from the furnace door 11 is provided with a smoke exhaust port, the bottom of the furnace wall 4 is provided with a grate 17, the lower part of the grate 17 is provided with an ash collection chamber 16, and the lower part of the furnace shell 1 is provided with a hot air chamber interlayer 12, The hot air bin interlayer 12 separates the two sides and the rear of the ash collecting chamber 16 into interconnected hot air bins 15; the hot air bin 15 is provided with a hot air outlet 14, and the hot air discharged from the hot air outlet 14 is transported to the place where hot air is needed through the hot air delivery pipe; The top of the furnace wall 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com