Three-dimensional printer, printing workbench applied to three-dimensional printer, paint, film and preparation method

A 3D printer and working platform technology, applied in the field of coatings and film layers, can solve the problems of cumbersome manufacturing methods and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

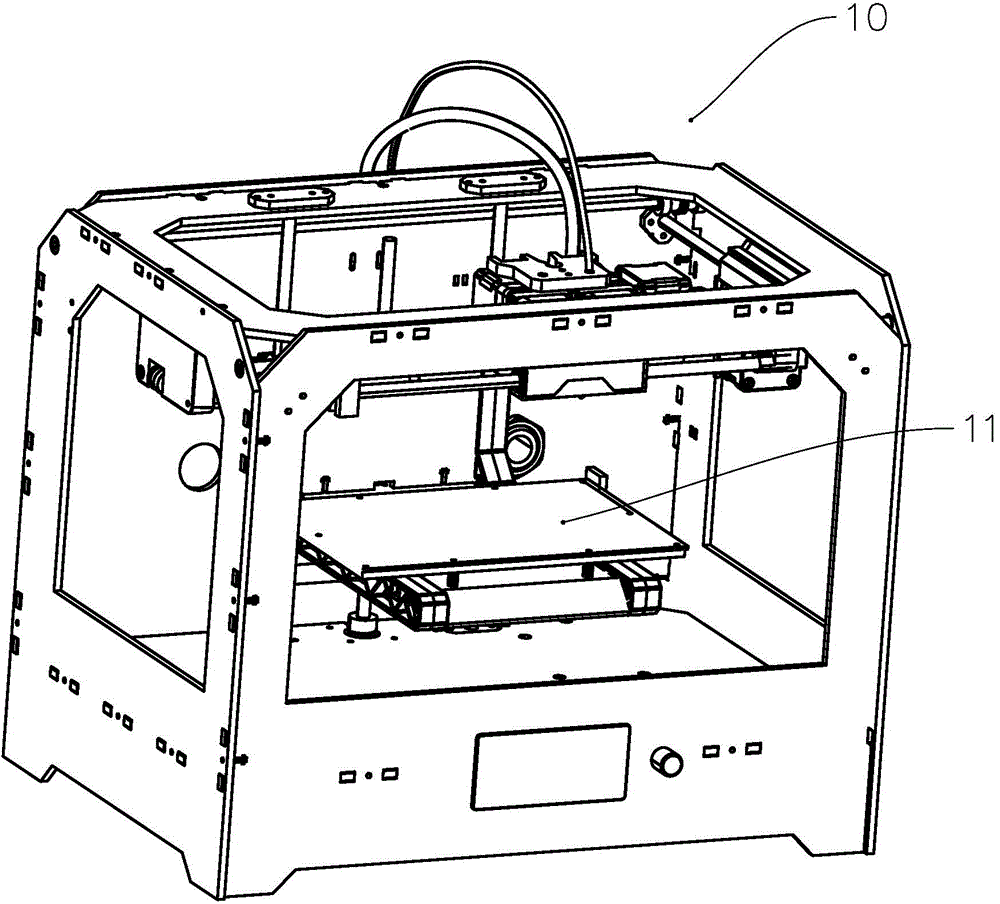

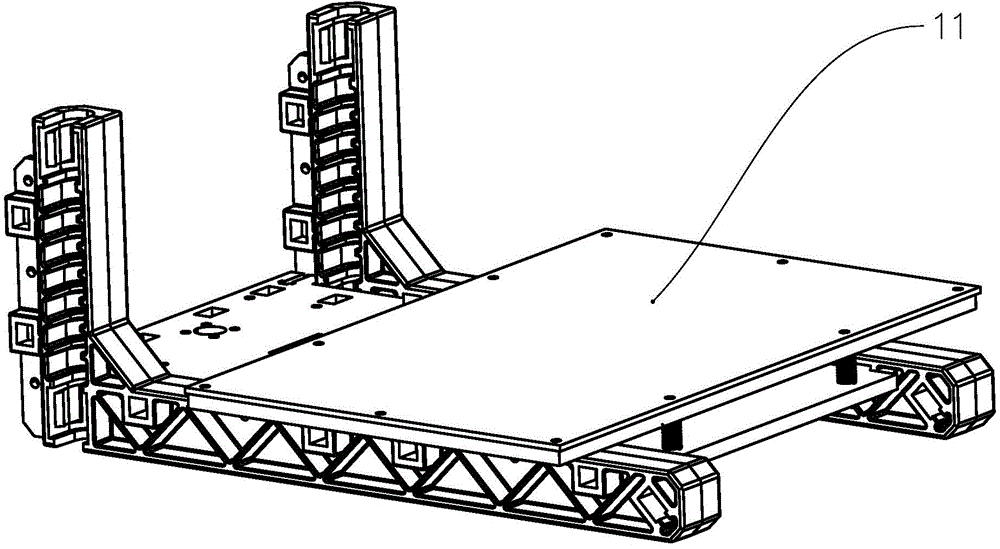

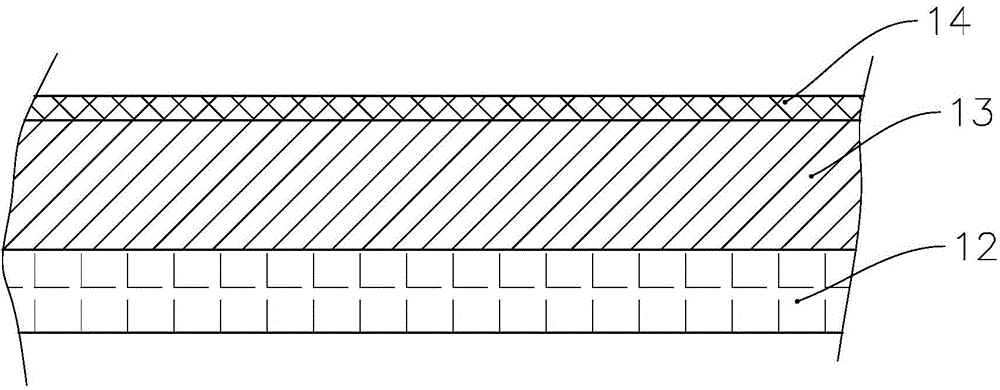

[0027] Such as figure 1 , figure 2 with image 3 As shown, the three-dimensional printer 10 provided by the present invention includes a printing table 11 , and the printing table 11 includes a heating layer 12 , a glass layer 13 and a film layer 14 sequentially from top to bottom. The paint provided in this embodiment is used for coating on the glass layer 11 . 12 parts by mass of heterocyclic acrylic resin, 24 to 28 parts by mass of weak solvent resin, and 10 to 14 parts by mass of thinner are uniformly mixed to obtain a coating.

[0028] Preferably, the weak solvent resin is acrylic resin, and the amount of acrylic resin is 26 parts by mass. The weak solvent resin is provided by Zhuhai Natural Baojie Digital Technology Co., Ltd., and the product model is NZZ009X.

[0029] Preferably, the diluent includes at least one of the following: ethyl acetate, amyl acetate, and butyl acetate, and the diluent is 12 parts by mass.

[0030]The preparation method of the hybrid acryli...

no. 2 example

[0032] The method for preparing the film layer on the printing workbench of the three-dimensional printer provided in this embodiment, the printing workbench includes a glass layer, and the film layer is attached to the glass layer; the method for preparing the film layer includes the following steps: adding 12 parts by mass of heterocyclic acrylic acid Resin, 24 to 28 parts by mass of weak solvent resin, 10 to 14 parts by mass of diluent, and mix uniformly to obtain a coating; spray the coating evenly on the glass layer, and bake at a temperature of 150°C to 180°C for 60 to 90 minutes to obtain the film layer. Preferably, the thickness of the film layer is 0.3 mm.

[0033] The hybrid acrylic resin is provided by Dongguan Xintiandi Technology Co., Ltd., and the product model is WZ510.

no. 3 example

[0035] The printing working platform applied on the three-dimensional printer provided by the present invention, the printing working platform includes a heating layer, a glass layer and a film layer in sequence; the film layer is composed of 12 parts by mass of heterocyclic acrylic resin and 24 to 28 parts by mass of weak solvent resin . The method for preparing a glass platform comprises the following steps: uniformly mixing 12 parts by mass of heterocyclic acrylic resin, 24 to 28 parts by mass of weak solvent resin, and 10 to 14 parts by mass of thinner to obtain a coating; uniformly spraying the coating on On the glass layer, bake at a temperature of 150° C. to 180° C. for 60 to 90 minutes to obtain a glass platform. After the glass platform is fixed on the heating layer, the printing working platform is formed. When the film layer of the glass platform is damaged, the operator can directly replace the new glass platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com