Anti-warping PVC building decoration film pasting process

A technology for architectural decoration and anti-warping, applied in decorative arts, architecture, building structure, etc., can solve the problems of the effect of building surface protection, warping at the edges, and peeling at the edges. Good protection, lower probability of warpage, and longer duration of warpage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

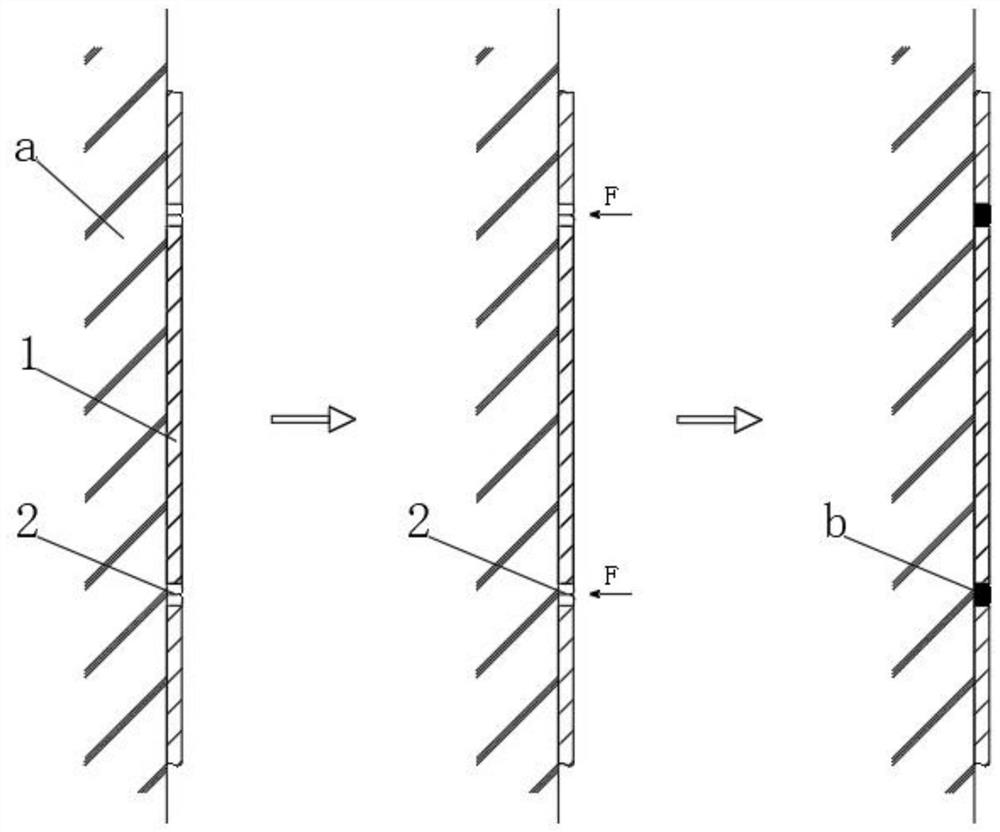

[0044] see figure 1 , a kind of anti-warping PVC architectural decorative film sticking process, comprises the following steps:

[0045] S1. Firstly, clean the dust and dross of the building surface that needs to be pasted with the decorative film;

[0046] S2. Align the adhesive surface of the rolled decorative film with the building surface, and attach it along the edge of the building surface;

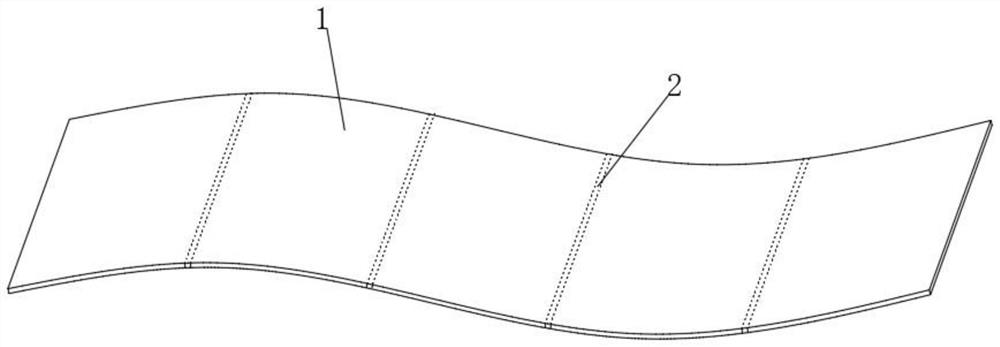

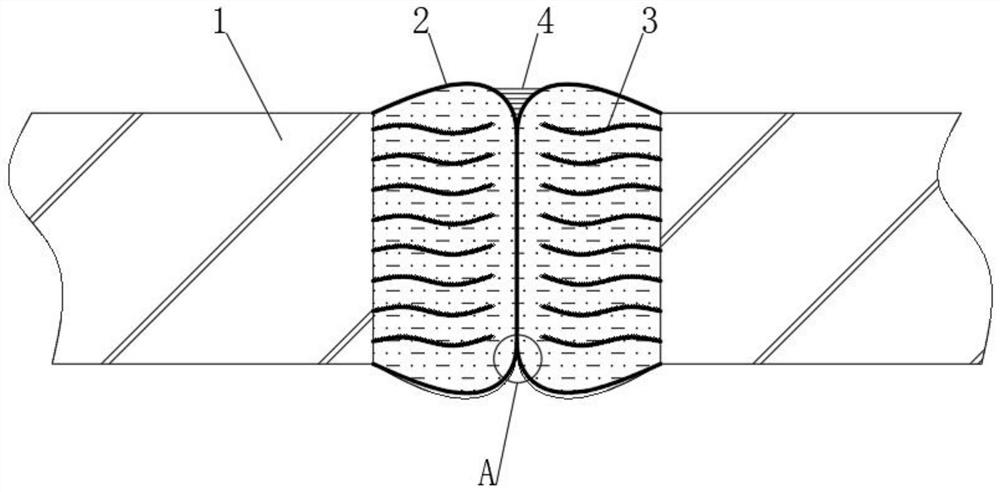

[0047] S3. Use a plate-shaped tool with a smooth surface to evenly press the anti-warp capsule 2 on the edge of the outermost diaphragm 1 and the anti-warp capsule 2 between the two diaphragms 1;

[0048] S4. The anti-warping capsule 2 is broken, and the film-forming glue inside overflows and flows. The film-forming glue is made of hot-melt material, so that the anti-warping glue is formed at the junction of the two diaphragms 1 and the edge of the diaphragm 1 layer, let it dry to complete the pasting of the decorative film.

[0049] In S3, the plate-shaped tool is preheated befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com