Casting-grade PVC decorative film and preparation method thereof

A film and functional layer technology, which is applied in the field of casting grade PVC decorative film and its preparation, can solve the problems of poor forming performance, poor dimensional stability, easy precipitation of small molecules, etc., and achieve improved tensile properties and toughness, high toughness and tensile strength, the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

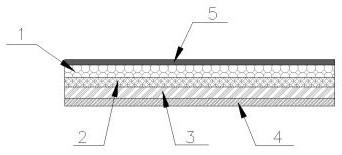

Image

Examples

Embodiment 1

[0027] The preparation method of the casting-grade car film is shown in process step 2, without adding a pressure-sensitive adhesive layer, and the steps are as follows:

[0028] Step 1: Preparation of functional layer: Dissolve polyvinyl chloride powder in an organic solvent, add toughening agent SBS, plasticizer, colorant, stabilizer, UV-resistant additive, dispersant and other additives, fully stir and heat Coating is performed on release paper after vibration, and forced drying is performed after coating.

[0029] Step 2: Prepare the protective layer: dissolve polyvinyl chloride powder in an organic solvent, mix plasticizers, stabilizers and other additives, heat and vibrate, and coat the dried functional layer. After coating Force dry.

[0030] Wherein, the mass ratio of PVC powder, solvent, plasticizer, SBS, colorant, stabilizer and auxiliary agent in the functional layer described in step 1 is 10:75:9:1:3:0.2:1.8; The mass ratio of PVC powder, solvent, plasticizer and...

Embodiment 2

[0043] Except that the mass ratio of PVC powder, solvent, plasticizer, TPU, colorant, stabilizer, and auxiliary agent in the functional layer prepared in step 1 is 9:75:8:3:3:0.2:1.8, other conditions are the same Example 1.

Embodiment 3

[0045]Except that the mass ratio of PVC powder, solvent, plasticizer, colorant, stabilizer, and auxiliary agent in the preparation of the functional layer in step 1 is 11:75:9:3:0.2:1.8, other conditions are the same as in Example 1. White film, without toughener SBS and TPU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com