Feed Mixing Plant for Animal Husbandry

A production device and feed technology, applied in feed, mixer, mixer with rotating container, etc., can solve the problems of slow mixing speed, complicated operation, uneven mixing, etc., achieve stable rotation, improve the quality of finished products, and improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

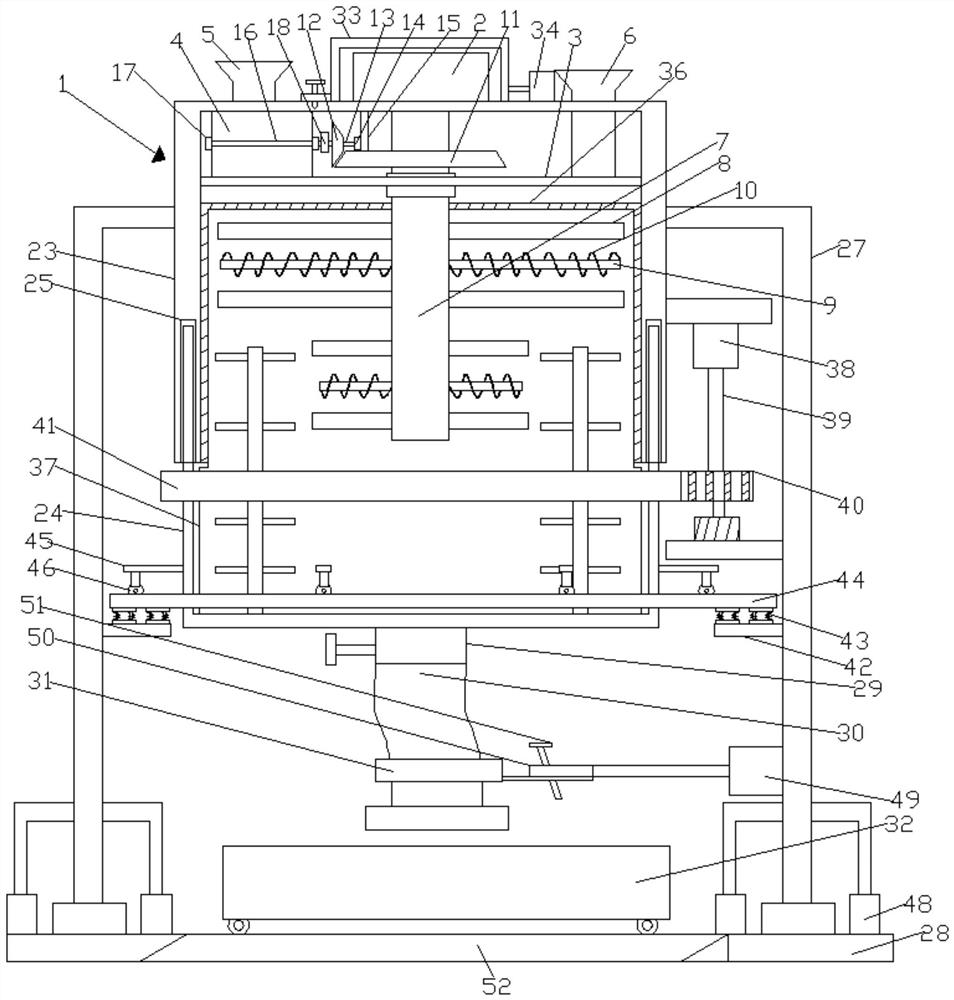

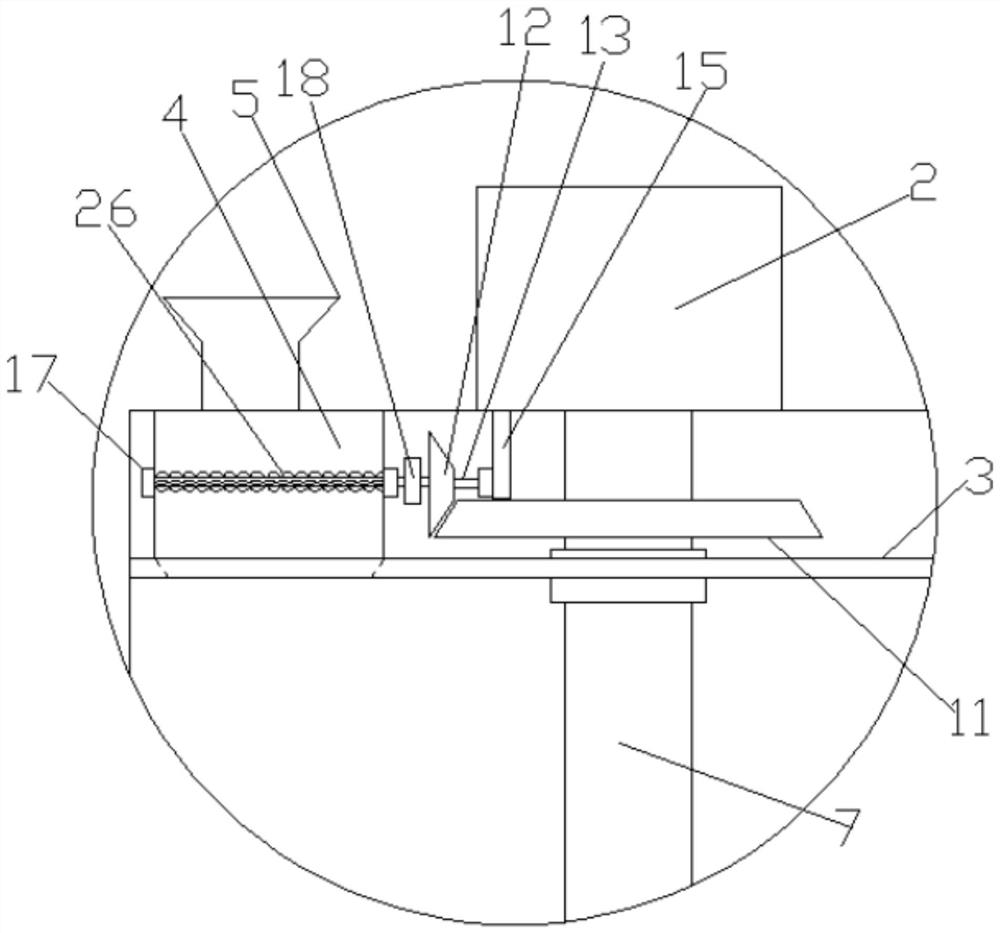

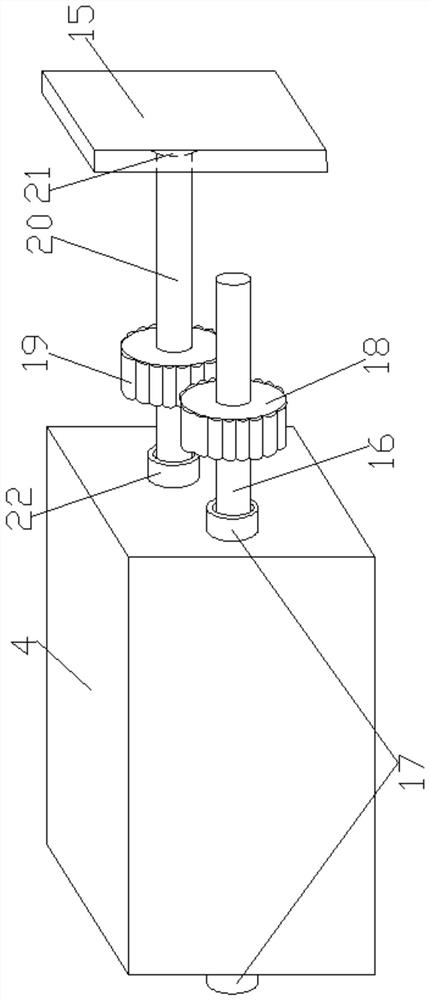

[0033] see Figure 1-8 According to the embodiment of the present invention, the animal husbandry feed mixing production device includes a working chamber 1, a motor 2 is fixed at the top center of the outer wall of the working chamber 1, and a noise reduction and heat dissipation mechanism is provided on the motor 2. The working chamber 1. The top of the inner top is fixed with a partition 3, and the top of the partition 3 is fixed with a crushing bin 4. The bottom of the crushing bin 4 is open, and the bottom of the crushing bin 4 runs through the partition 3 and the The interior of the working chamber 1 is connected, and the top of the crushing chamber 4 is fixed with a first feeding pipe 5, the first feeding pipe 5 is integrally formed with the crushing chamber 4, and the first feeding pipe 5 The top feeding port of the working chamber 1 extends above the top of the working chamber 1, and the top of the working chamber 1 is provided with a second feeding pipe 6, and the ou...

Embodiment 2

[0035] see figure 1 , for the sound-absorbing heat-dissipating mechanism, the sound-absorbing heat-dissipating mechanism is a sound-proof cover 33 and a blower 34, the motor 2 is covered with the sound-proof cover 33, and the sound-proof cover 33 is installed on the top of the working chamber 1 by screws, The blower 34 is fixed on the top of the outer wall of the working warehouse 1, the air duct on the blower 34 is connected with the sound insulation cover 33, and the inside of the air duct communicates with the inside of the sound insulation cover 33, and the sound insulation The cover 33 is provided with several cooling holes.

[0036] Through the above scheme of the present invention, the beneficial effect is that the wind blown by the blower 34 is blown into the soundproof cover 33 through the air duct, and the heat generated by the motor 2 working for a long time is blown away, and finally discharged through the heat dissipation holes, and the heat dissipation holes can ...

Embodiment 3

[0038] see Figure 8 For the stirring plates 8, the number of stirring plates 8 are provided with material penetration holes 35, the number of stirring plates 8 arranged below are shorter than the number of stirring plates 8 arranged above, the upper working chamber 23 and the lower The working bins 24 are circular bins.

[0039] Through the above scheme of the present invention, the beneficial effect is that the stirring plate 8 is provided with a feeding hole 35, and when the feed is mixed, it passes through the feeding hole 35, thus speeding up the mixing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com