A garbage transport device

A technology for conveying devices and domestic garbage, applied in trash cans, garbage collection, household utensils, etc., can solve the problems of blockage of garbage input ports, increased labor intensity, and unclean dumping, etc., to prevent blockage, facilitate collection, and facilitate disposal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

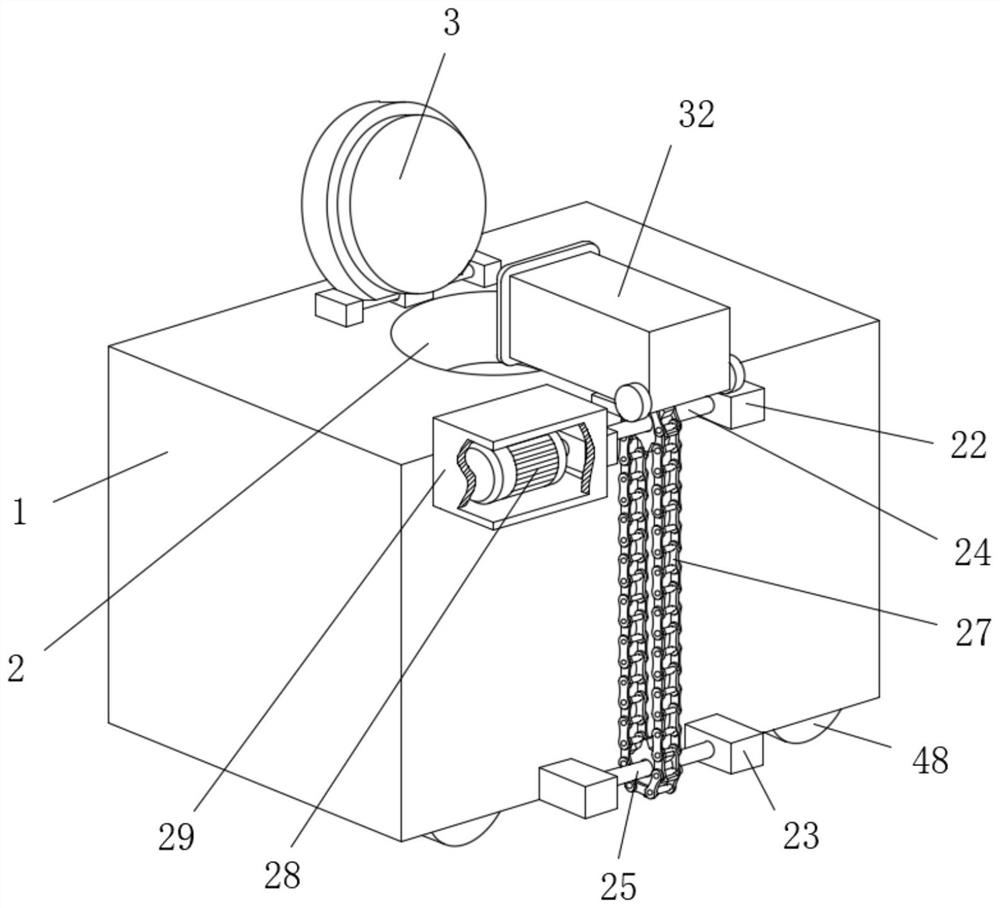

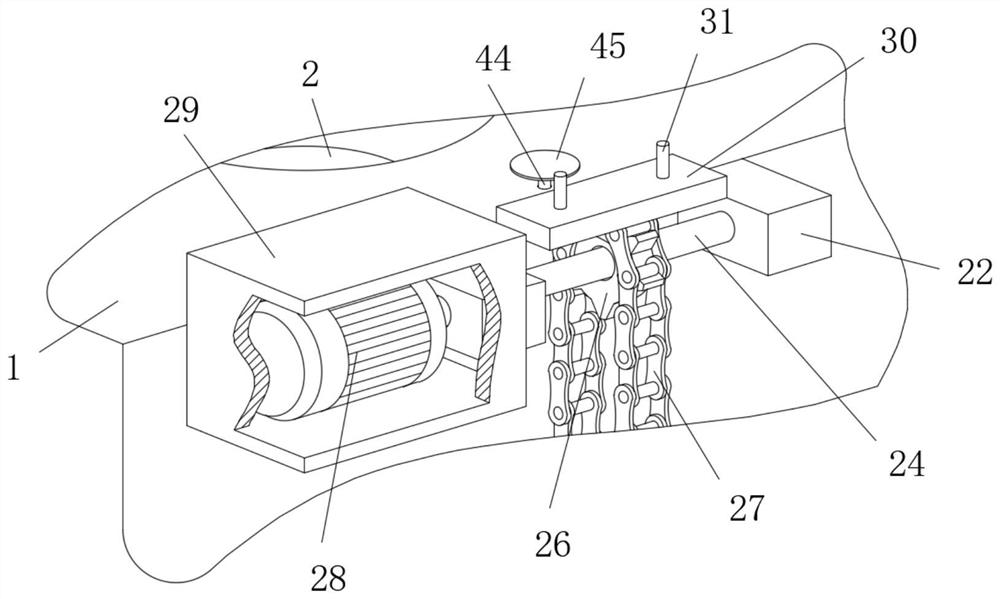

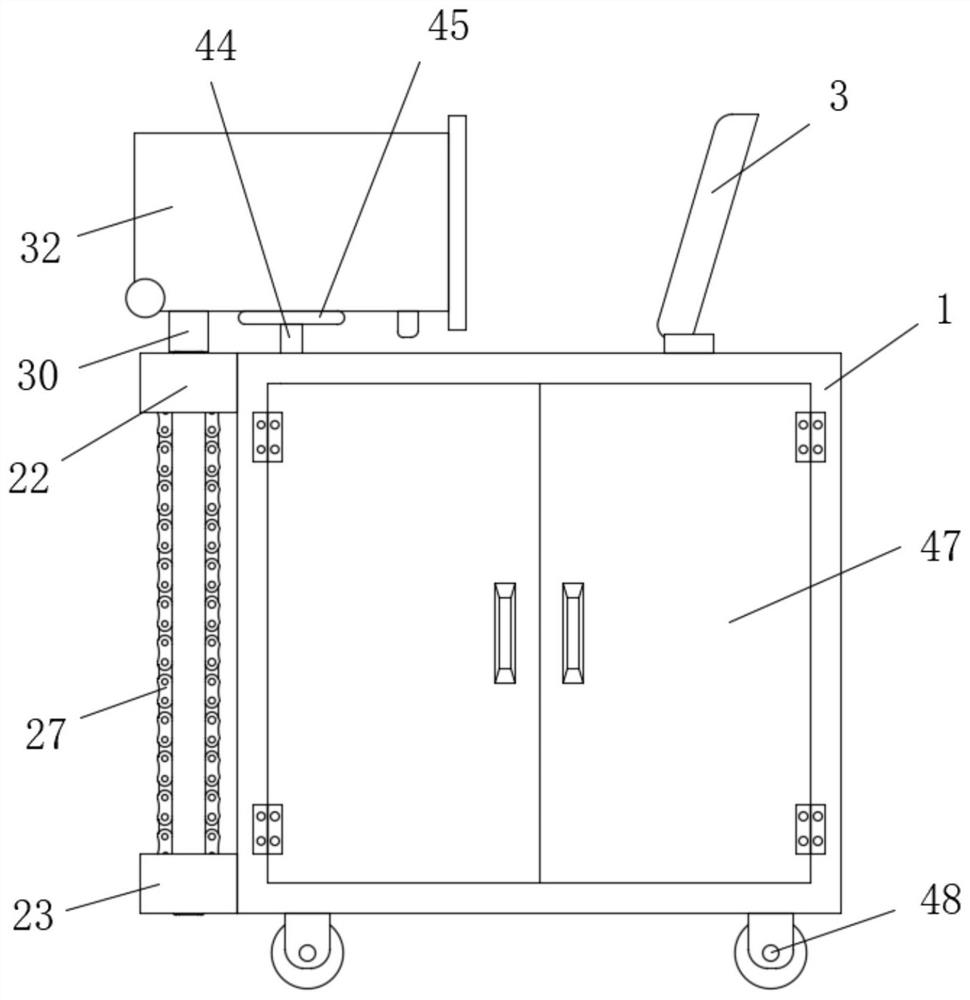

[0034] refer to Figure 1-8 , a living garbage conveying device, comprising a box body 1, the top of the box body 1 is penetrated and fixedly connected with an input bucket 2, and the top outer wall of the box body 1 is rotatably connected with a cover plate 3, and the cover plate 3 is matched with the input bucket 2, Two movable plates 6 are symmetrically slidably connected to the inner wall of the side of the box body 1 away from each other, and a first groove 7 is provided on the side where the two movable plates 6 are close to each other. In the same solid collection box 8, one side of the input bucket 2 extends to the inner wall of the box body 1 and cooperates with the solid collection box 8. Two fixed plates 14 are symmetrically fixedly connected to the inner wall of the side of the box body 1 away from each other, and the two The bottoms of the two fixing plates 14 are respectively in contact with the bottom inner wall of the box body 1, and the sides where the two fix...

Embodiment 2

[0036] Further improvement on the basis of Embodiment 1: the four corners of the movable plate 6 away from the solid collection box 8 are fixedly connected with slide bars 5, and the sides of the four slide bars 5 away from the movable plate 6 are all slidably sleeved. Sleeve 4, and one end of four sleeves 4 is fixedly connected with the inner wall of one side of box body 1 respectively, through the cooperation of sleeve 4 and slide bar 5, can play the effect of stably supporting and sliding movable plate 6, slide bar 5. One end located inside the sleeve 4 is fixedly connected with a first return spring 9, and the other end of the first return spring 9 is fixedly connected with the inner wall of one side of the sleeve 4. The first return spring 9 can act on the slide bar 5. Reset effect, the side of solid collection box 8 close to box door 47 is symmetrically fixedly connected with two first clamping columns 10, and the side of two movable plates 6 near box door 47 is all rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com