Conical lock for integrated template

An integrated, conical technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc. Formwork panels and other problems, to achieve the effect of reducing labor intensity of workers, convenient and orderly cross-operation, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples. Diameter Φ, thickness δ.

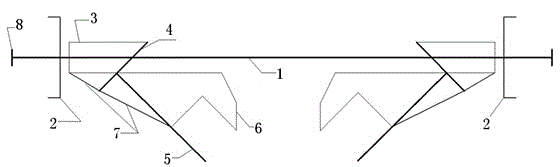

[0022] Such as figure 1 As shown, an integrated formwork tapered lock includes a locking rod 1, two ingot lock nuts 2, two tapered clips and two plugs 8, and the two ends of the locking rod 1 are respectively threaded and provided with a movable The ingot lock mother 2; the tapered card includes a lock tube 3, a support plate 4, a card plate 5, a lock jaw 6, and ribs 7; the lock tube 3 is set on the lock rod 1, and one end is close to the ingot lock mother 2 and passes through The other end of the ingot lock mother is limited, and the other end is connected with a support plate 4, a clamp plate 5 is welded on the support plate, and a lock jaw 6 is welded on the clamp plate. The bayonet formed by the clamp plate 5 and the lock jaw 6 is matched with the frame of the template to be reinforced Right-angle U-shaped structure. The lock jaw 6 is stuck on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com