Dehydration sand mixing machine

A technology of mud and sand and driving mechanism, which is applied in the field of construction machinery, and can solve problems such as affecting equipment and being unable to remove sand and iron impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

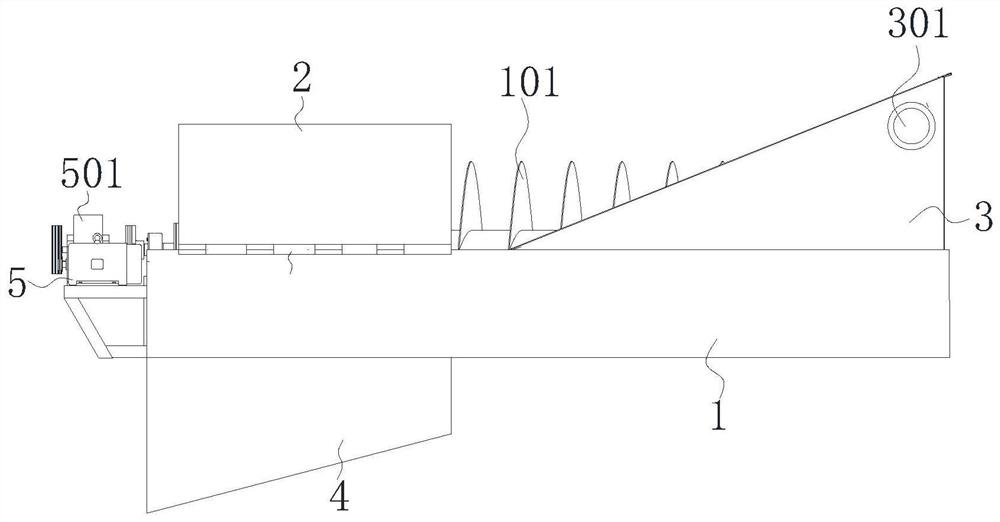

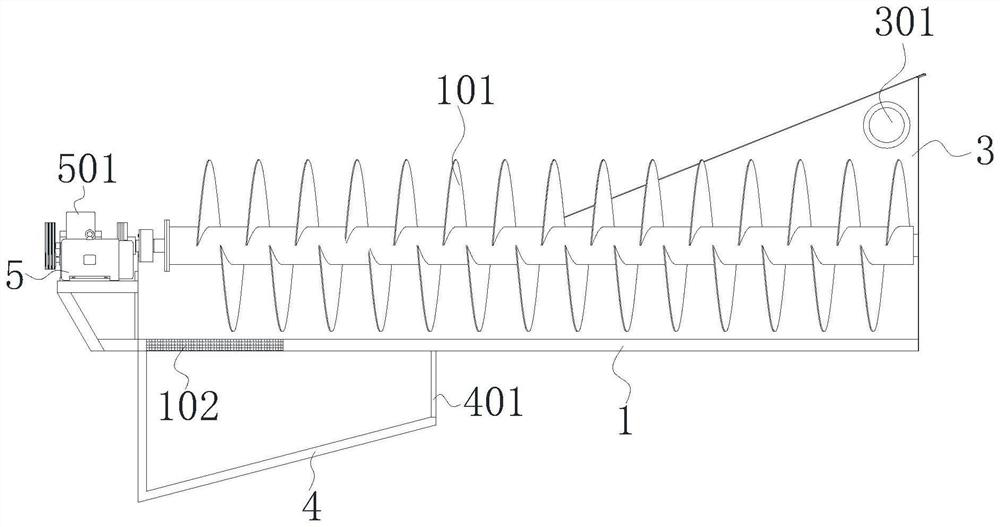

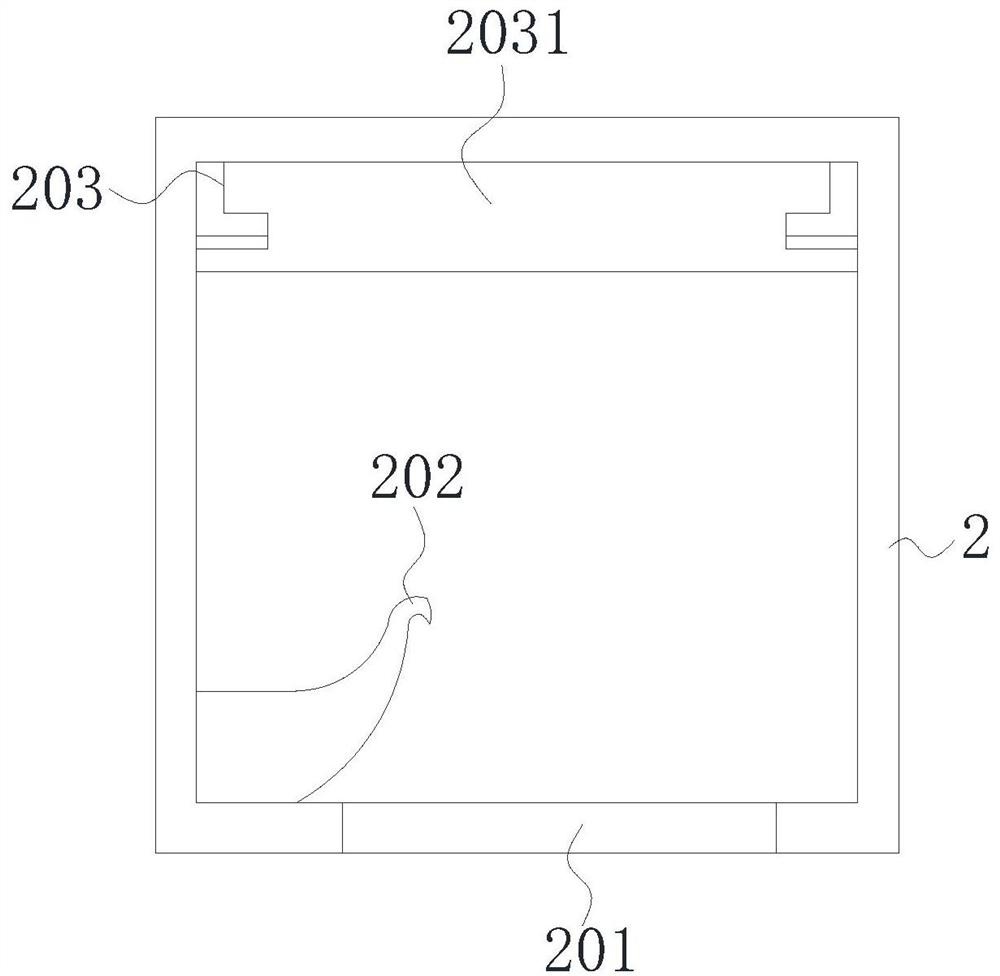

[0034] Please refer to Figure 1 to Figure 3 , figure 1 Shown is a schematic diagram of the overall structure of the dewatering sand mixer described in the embodiment of the present invention; figure 2 Shown is a partial perspective structure diagram of the dewatering sand mixer described in the embodiment of the present invention; image 3 Shown is a schematic cross-sectional structure diagram of the partition box described in the embodiment of the present invention.

[0035]This embodiment provides a dehydration sand mixing machine, comprising a mud-sand separation tank. The mud-sand separation tank 1 is provided with an auger 101 connected to a drive mechanism at the end, and a magnet 1011 is arranged along the edge of the impeller of the auger 101. The mud-sand separation tank is located at The top opening 401 is covered with a partition box 2, and the end of the mud-sand separation tank 1 away from the partition box 2 is provided with a mud-sand pool 3. A scraper 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com