Rotary lifting appliance of electromagnetic plate crane

A technology of rotating spreader and crane, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unreasonable structure design, poor sealing, complicated structure of rotating spreader, etc., to achieve fewer failure points and reduce the number of parts and components. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

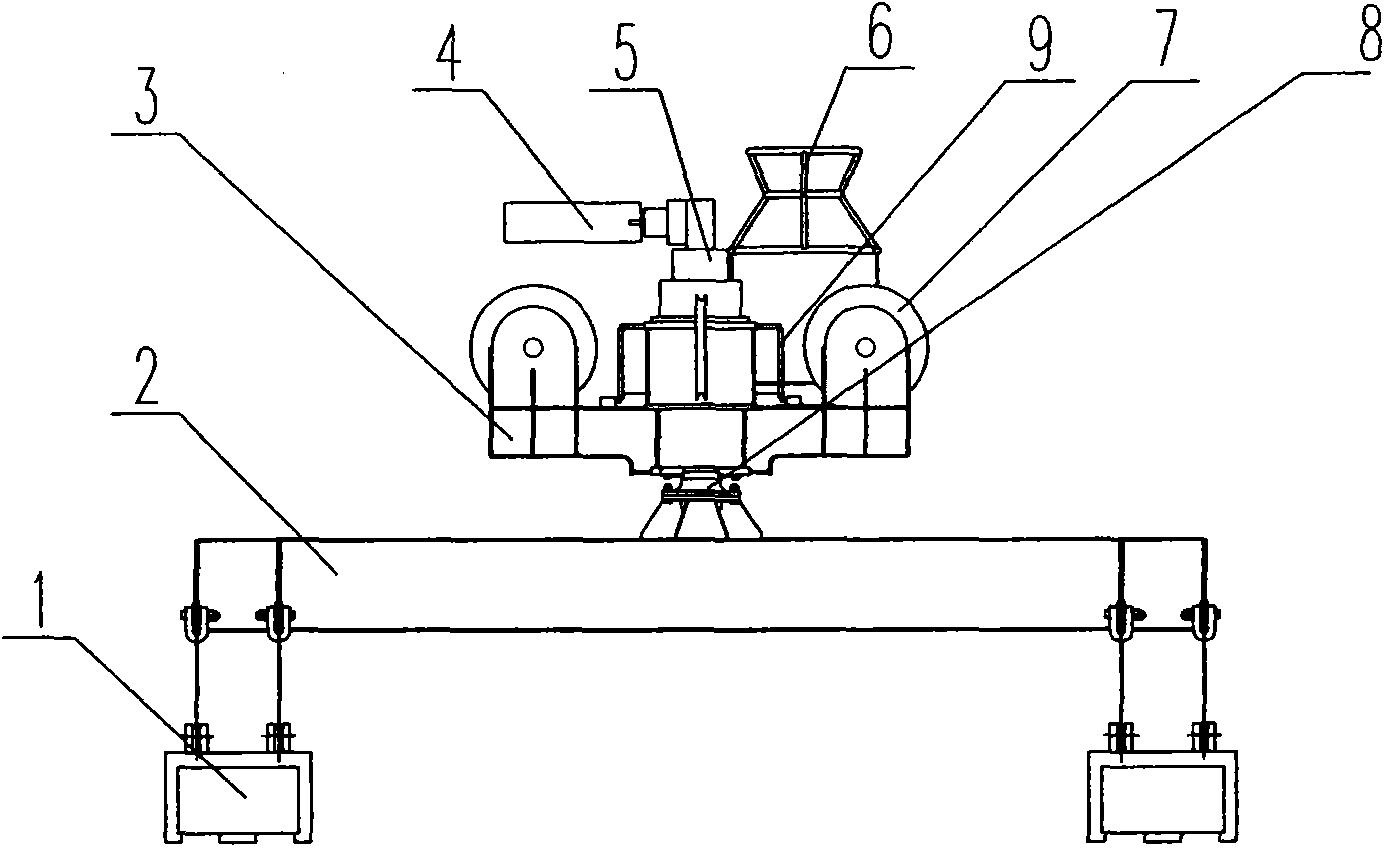

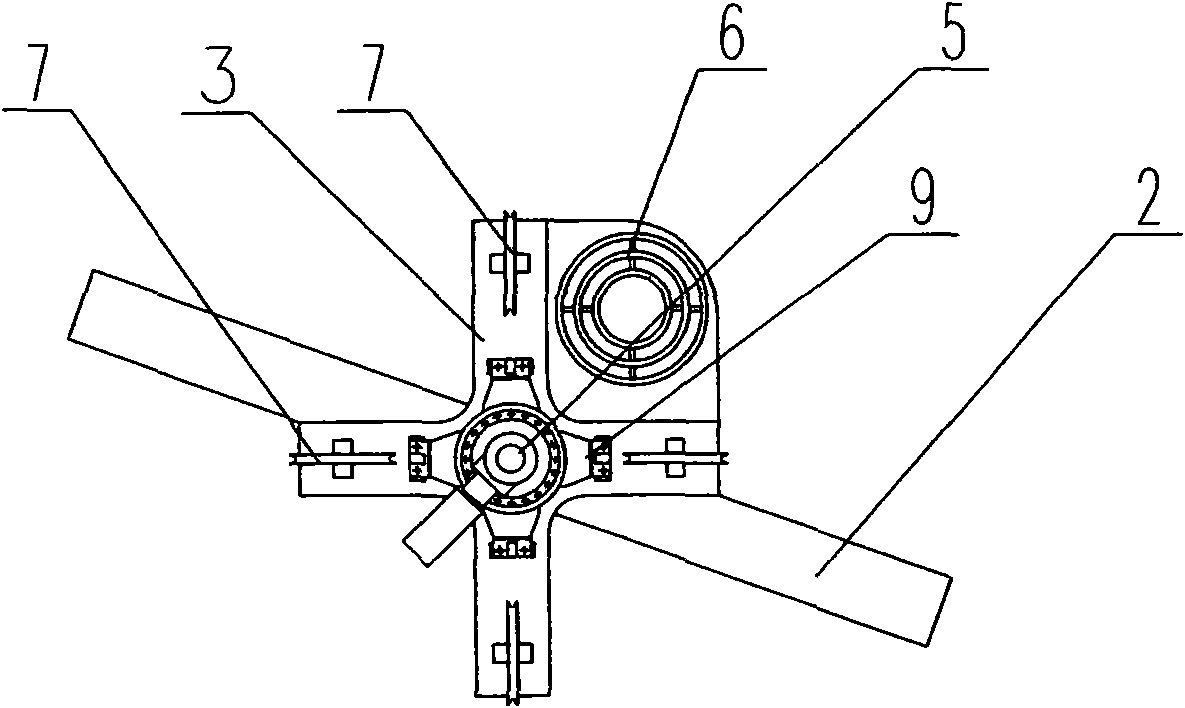

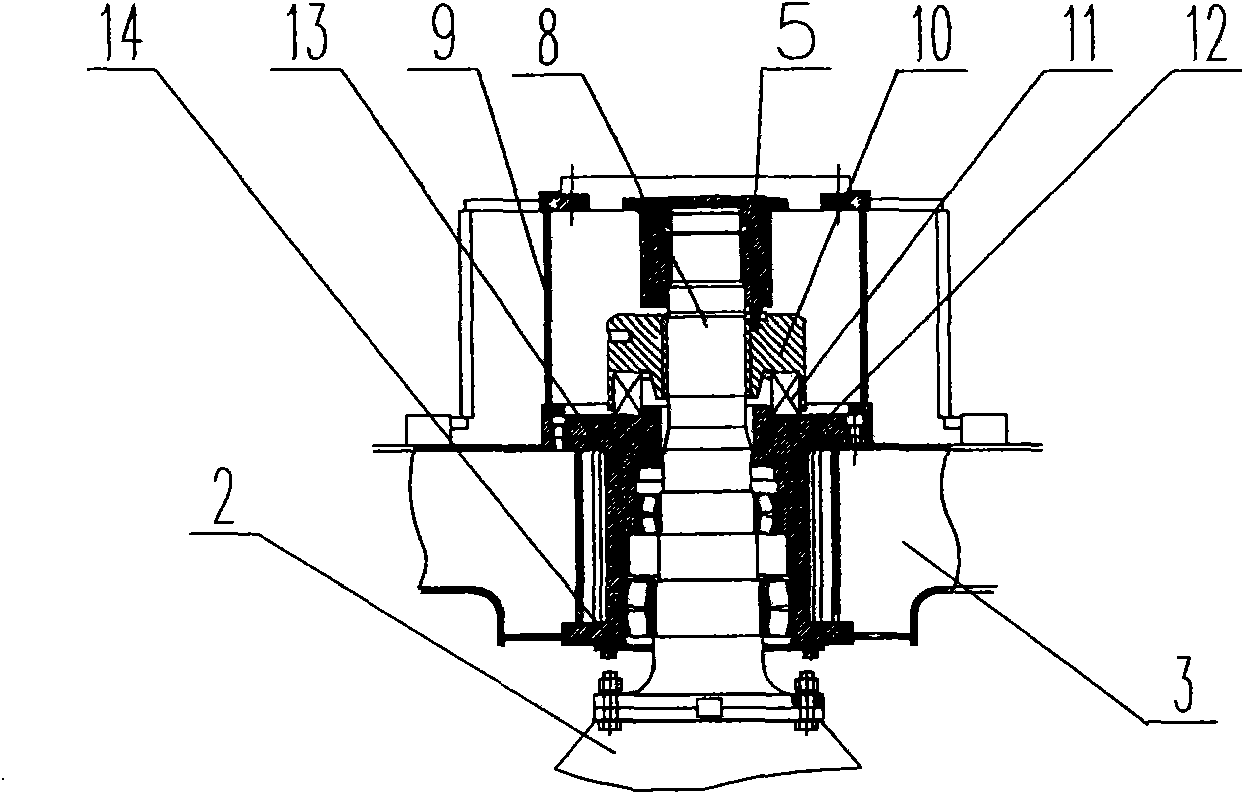

[0020] Such as figure 1 , 2 As shown in , 3, a rotating hoist for an electromagnetic disk crane includes: an electromagnetic hanging beam 2, an electromagnetic disk 1 that is flexibly connected to the lower end of the electromagnetic hanging beam 2, and is characterized in that: the electromagnetic hanging beam 2 is provided with a The crossbeam 3 connected by the driving mechanism of the rotating sling, the driving mechanism of the rotating sling consists of a motor 4, a reducer 5, a rotating shaft 8, a reducer support 9, a hook nut 10, a thrust bearing 11, and a bearing seat 12 , a positioning bearing 13, and a sealing flange 14; the motor 4 drives the reducer 5, the inner spline of the output shaft of the reducer 5 cooperates with the outer spline of the rotating shaft 8 to drive the rotating shaft 8 to rotate, The lower end flange of the rotating shaft 8 is bolted to the end flange of the electromagnetic hanging beam 2, the upper thread of the rotating shaft 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com