Anti-shaking device for crane

An anti-rolling device and crane technology, which are applied to cranes, trolley cranes, transportation and packaging, etc., can solve problems such as accurate positioning and accurate stacking of unfavorable goods, difficult to determine the landing point of heavy objects, and difficult landing of heavy objects. , to facilitate positioning and stacking, improve work efficiency and safety, and facilitate stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

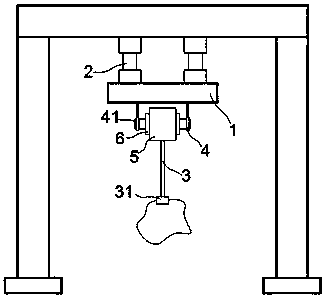

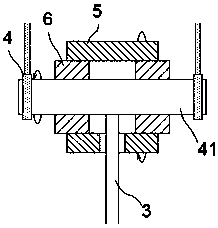

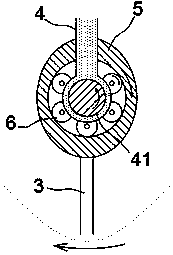

[0016] exist Figure 1 to Figure 3 In the shown embodiment, the crane includes a support frame, a main girder, a running trolley 1, a lifting mechanism 2, a sling 3 and a hook 31 installed on the lower part of the sling 3, and the crane anti-sway device is installed on the running trolley 1 At the bottom, the crane anti-sway device includes a support ring 4, which is fixed on the running trolley; a horizontal central shaft 41 is set in series in the support ring 4, and the central shaft 41 can only be around its own axis, Rotate freely relative to the support ring 4; the anti-sway cylinder 5 is coaxially sleeved on the outside of the central shaft 41, and the anti-sway cylinder 5 and the central shaft 41 are meshed by a reverse gear set 6; The cranking cylinder 5 and the central shaft 41 can also be engaged and transmitted through the acceleration gear set. The present invention is not limited to the above two meshing modes. The selected connection structure only needs to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com