High-temperature alloy honeycomb core and corrugated board stacking method and device

A high-temperature alloy and honeycomb core technology, applied in chemical instruments and methods, layered products, lamination auxiliary operations, etc., to achieve the effects of short process, high precision, and high device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

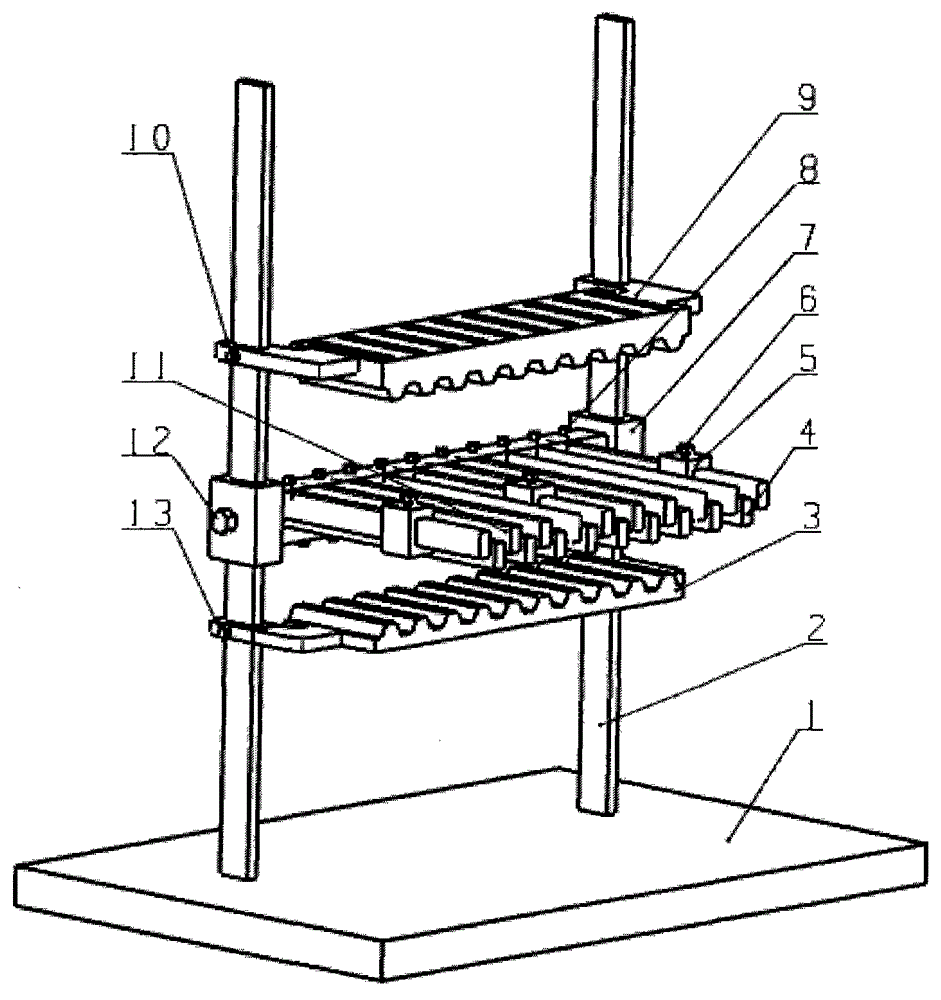

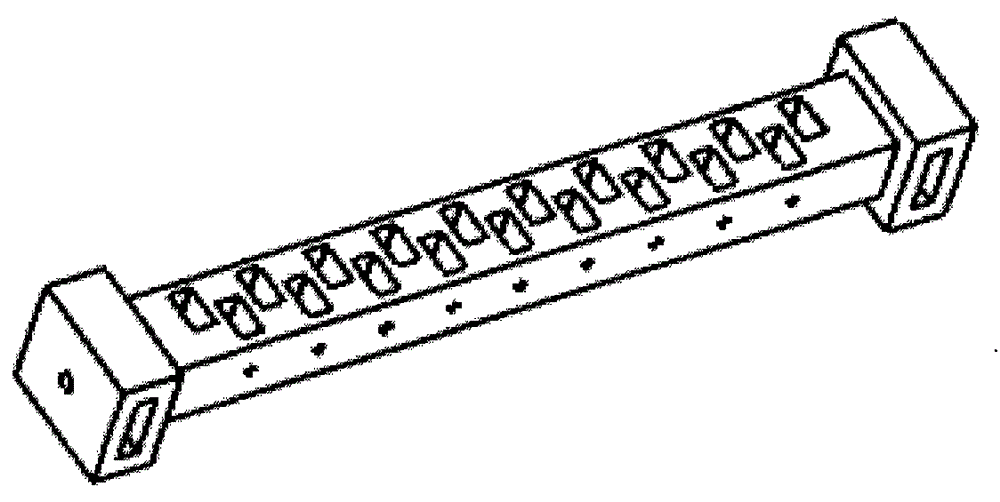

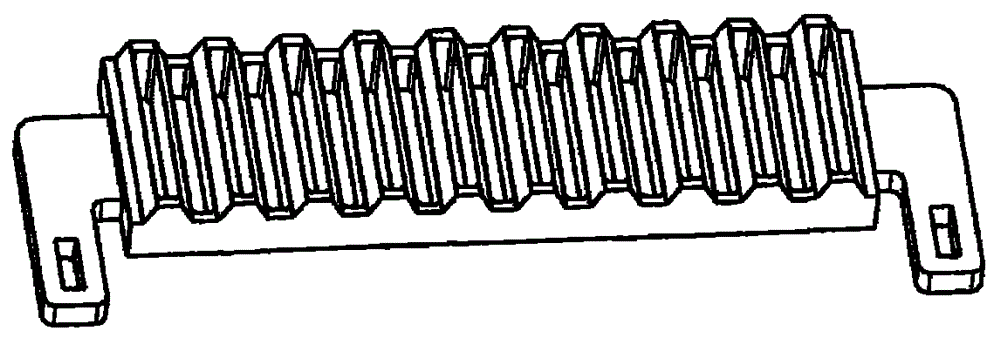

[0035] A superalloy honeycomb core semi-regular hexagonal lattice corrugated board stacking device, including a support plate 1, a support rod 2, a limit plate 3, a positioning mandrel 4, a limit block 5, a limit fastening screw 6, and a rising positioning block 7. The first adjusting fastening screw 8 , the pressing plate 9 , the second adjusting fastening screw 10 , the support mandrel 11 , the third adjusting fastening screw 12 and the fourth adjusting fastening screw 13 . Wherein, the support rod 2 is welded or screwed on the support plate 1 for positioning; the limit block 5 is a square ring, which can move back and forth along the support mandrel 11, and the limit fastening screw 6 on the limit block 5 The supporting mandrel 11 is fastened and positioned; the positioning mandrel 4 and the supporting mandrel 11 are fastened and positioned on the rising positioning block 7 by the first adjusting fastening screw 8; the limit plate 3 is supported by the fourth adjusting faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com