Roll-weakening device of crane

A technology of anti-rolling devices and cranes, which is applied in hoisting devices, transportation and packaging, clockwork mechanisms, etc., and can solve problems such as precise positioning and accurate stacking of unfavorable goods, potential safety hazards, damaged ground and heavy objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

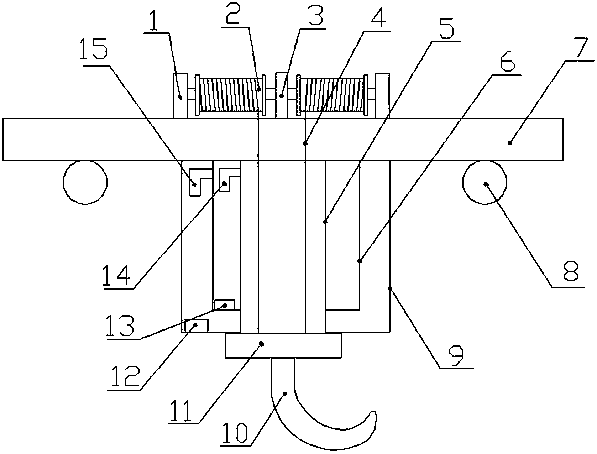

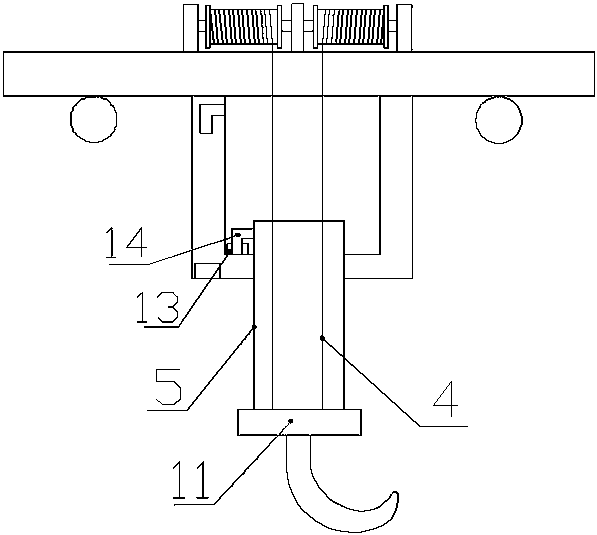

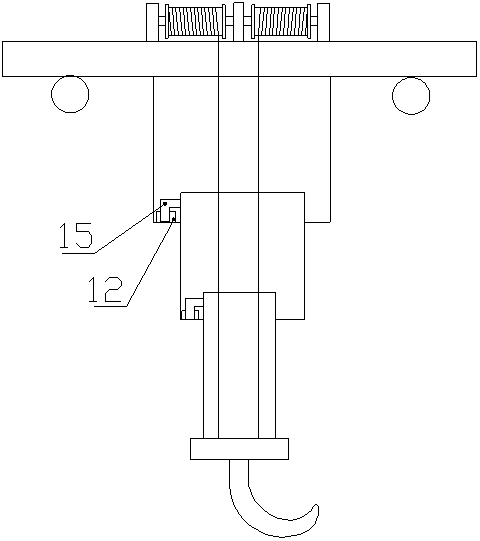

[0017] like Figure 1-4 Shown, a kind of anti-rolling device of crane, it comprises trolley 7, and described trolley 7 is equipped with wheel 8 on both sides of the lower end, and the middle part of the lower end of described trolley 7 is welded with outer cylinder 9, and described outer cylinder 9 is sleeved with a middle cylinder 6, said middle cylinder 6 is sleeved with an inner cylinder 5, said outer cylinder 9 is provided with a groove A12 on the left side of the inner lower end, said middle cylinder 6 has a top left side A protrusion A15 matching with the groove A12 is fixedly connected, a groove B13 is provided on the left side of the inner lower end of the middle cylinder 6, and a groove B13 is fixedly connected on the upper left side of the inner cylinder 5 to match the groove B13. The protrusion B14, the upper end of the outer cylinder 9 and the middle cylinder 6 are provided with through holes, the upper end and lower end of the inner cylinder 5 are provided with th...

Embodiment 2

[0020] like Figure 1-4 Shown, a kind of anti-rolling device of crane, it comprises trolley 7, and described trolley 7 is equipped with wheel 8 on both sides of the lower end, and the middle part of the lower end of described trolley 7 is welded with outer cylinder 9, and described outer cylinder 9 is sleeved with a middle cylinder 6, said middle cylinder 6 is sleeved with an inner cylinder 5, said outer cylinder 9 is provided with a groove A12 on the left side of the inner lower end, said middle cylinder 6 has a top left side A protrusion A15 matching with the groove A12 is fixedly connected, a groove B13 is provided on the left side of the inner lower end of the middle cylinder 6, and a groove B13 is fixedly connected on the upper left side of the inner cylinder 5 to match the groove B13. The protrusion B14, the upper end of the outer cylinder 9 and the middle cylinder 6 are provided with through holes, the upper end and lower end of the inner cylinder 5 are provided with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com