Counting conveying stacking system for corrugated paper

A palletizing system and corrugated paper technology, applied in the field of corrugated cardboard production equipment, can solve problems such as inconvenience and difficult paper separation, and achieve the effects of simple operation, labor saving and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

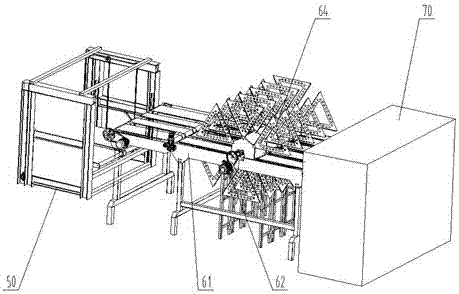

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the present invention includes a corrugated cardboard counting machine 70, a turning conveying mechanism and a dislocation stacker, and the turning conveying mechanism includes a corrugated cardboard conveying machine 61 and a turning mechanism,

[0024] The corrugated cardboard counting machine 70 includes a corrugated cardboard counting machine 70, an inversion conveying mechanism and a dislocation stacker, and the inverting conveying mechanism includes a corrugated paper conveyor 61 and an inverting mechanism,

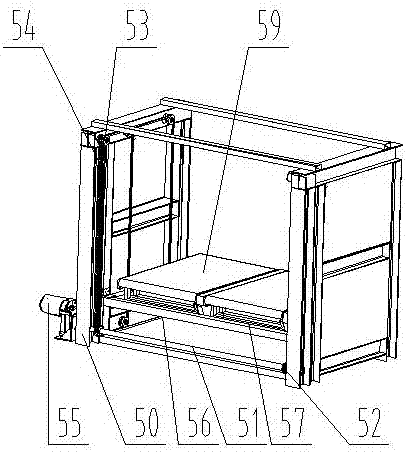

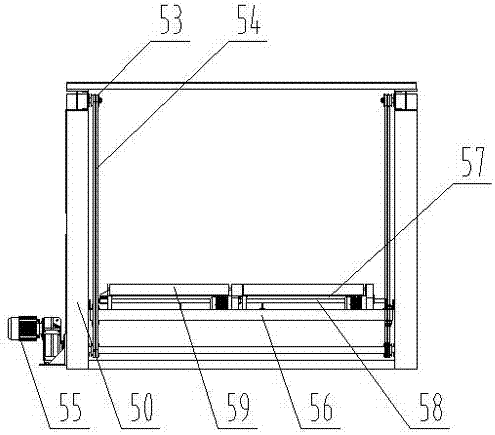

[0025] The corrugated cardboard counting machine 70 includes a paper separating frame 1, a chain plate lifting mechanism, a paper pushing mechanism and a paper separating baffle device. The chain plate lifting mechanism includes a chain plate conveyor 2, a lifting control motor 3 and a drive shaft 4, and the chain plate lifting mechanism A pair of rollers 6 are respectively arranged on both sides of the plate conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com