Glove stacking and counting machine

A glove and stacking technology, which is applied in the field of glove stacking and counting machines, can solve the problems of high maintenance of finished products, high frequency of pneumatic control, and impact on glove packaging, and achieve the effects of convenient packaging, neat stacking, and accurate quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

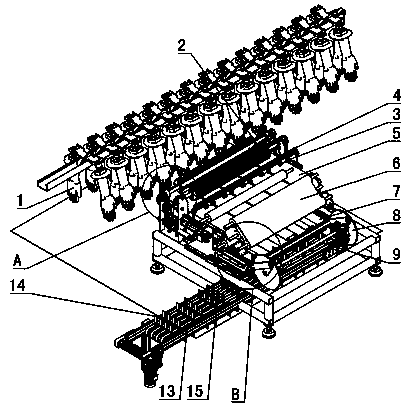

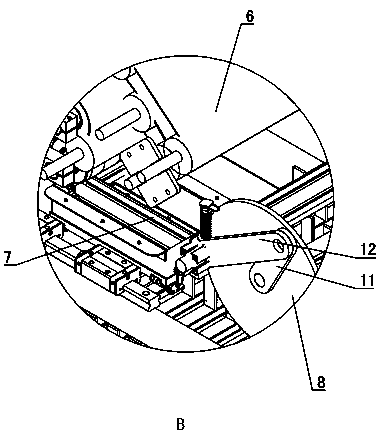

[0038] Such as Figure 1~3 As shown: the transfer conveyor belt 5 and the clamping conveyor mechanism 6 are installed on the frame 10, the transfer conveyor belt 5 is arranged horizontally, the clamping conveyor mechanism 6 is arranged at the output end of the transfer conveyor belt 5, and the stacking bin 7 is slidably installed on the On the frame 10, and the stacking bin 7 is arranged directly below the output end of the clamping conveying mechanism 6 .

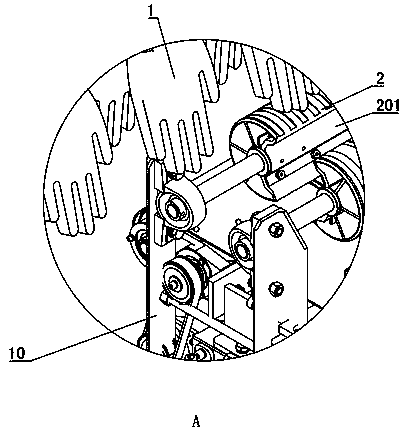

[0039] Rotate on the frame 10 and be equipped with horizontal pick-up roller 2, pick-up roller 2 has two, two pick-up rollers 2 are parallel and set at intervals, the axis of pick-up roller 2 is perpendicular to the conveying direction of transfer conveyer belt 5, two Two picking rollers 2 are arranged at intervals directly above the input end of the transfer conveyor belt 5 . A plurality of grooves are arranged at intervals around the sides of the two picking rollers 2 , thereby increasing the friction between the pickin...

Embodiment 2

[0055] The difference between Embodiment 2 and Embodiment 1 is that the clamping and conveying mechanism 6 is a clamping manipulator, and the clamping manipulator clamps and stacks the gloves on the transfer conveyor belt 5 in the stacking bin 7, thereby completing the stacking of gloves .

Embodiment 3

[0057] Such as Figure 8 As shown: the difference between embodiment 3 and embodiment 1 is that: the upper side of the two output conveyor belts 13 and the converging conveyor belt 19 is provided with a gantry manipulator, and the gantry manipulator will converge the gloves on the two output conveyor belts 13 to the converging conveyor belt 19, thereby completing the delivery of gloves.

[0058] The gantry manipulator comprises a gantry frame and two grippers 24 installed on the crossbeam of the gantry frame 25. Two translation motors 26 are installed on the crossbeam of the gantry frame 25. Gears are installed on the output shaft of each translation motor 26, and the crossbeam A rack that meshes with two gears simultaneously is installed on the top, thereby realizing the translation of two translation motors 26 . A lift cylinder is installed on each translation motor 26, and a swing cylinder 23 is installed on the piston rod of the lift cylinder, and the jaws 24 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com