Automatic stacking machine for printed matter checkout machine

A technology of automatic stacking and inspection machine, which is applied to stacking receiving devices, sending objects, thin material handling, etc. Achieve the effect of short paper output time, shorten paper output time and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

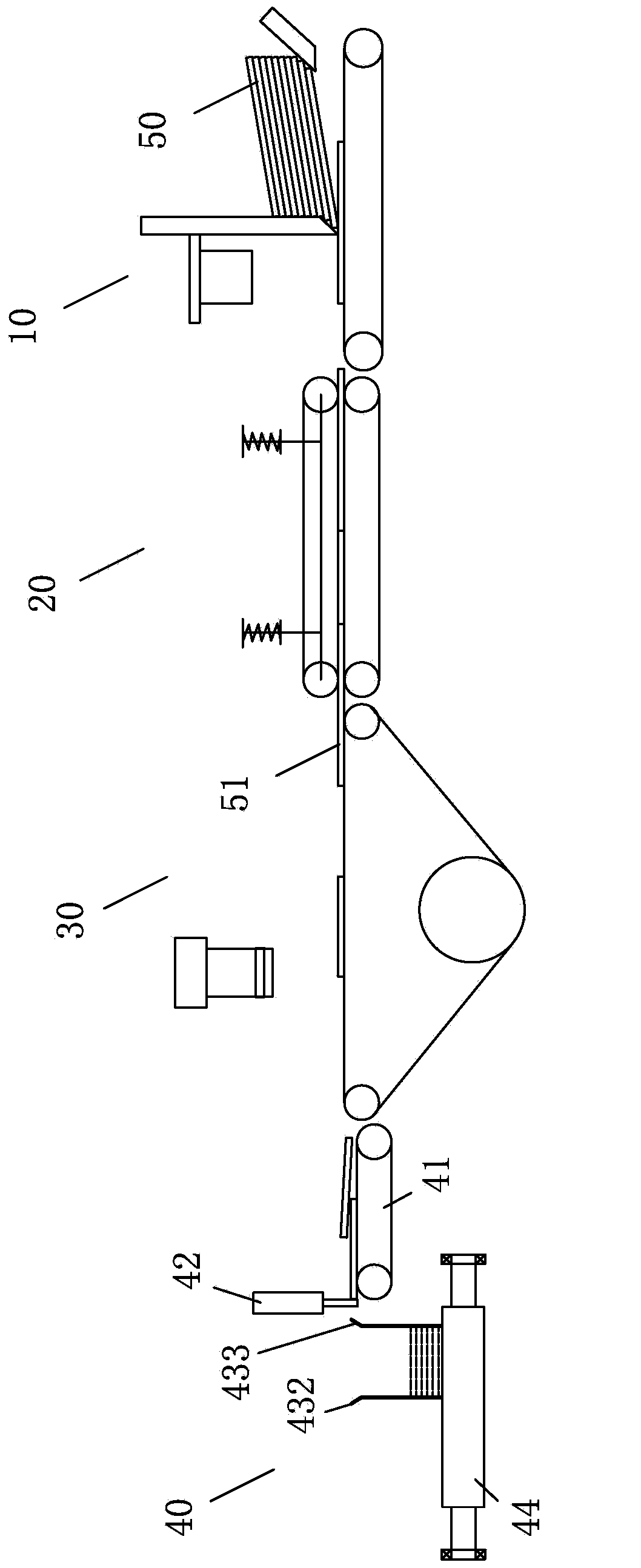

[0032] The automatic stacker for the product inspection machine of the present invention is used for the product inspection machine, also known as the small-sheet printed matter inspection machine, and the product inspection machine generally includes a paper feeder (not shown in the figure), a deviation correction ), surface quality inspection machine (not shown in the figure) and automatic stacker of the present invention.

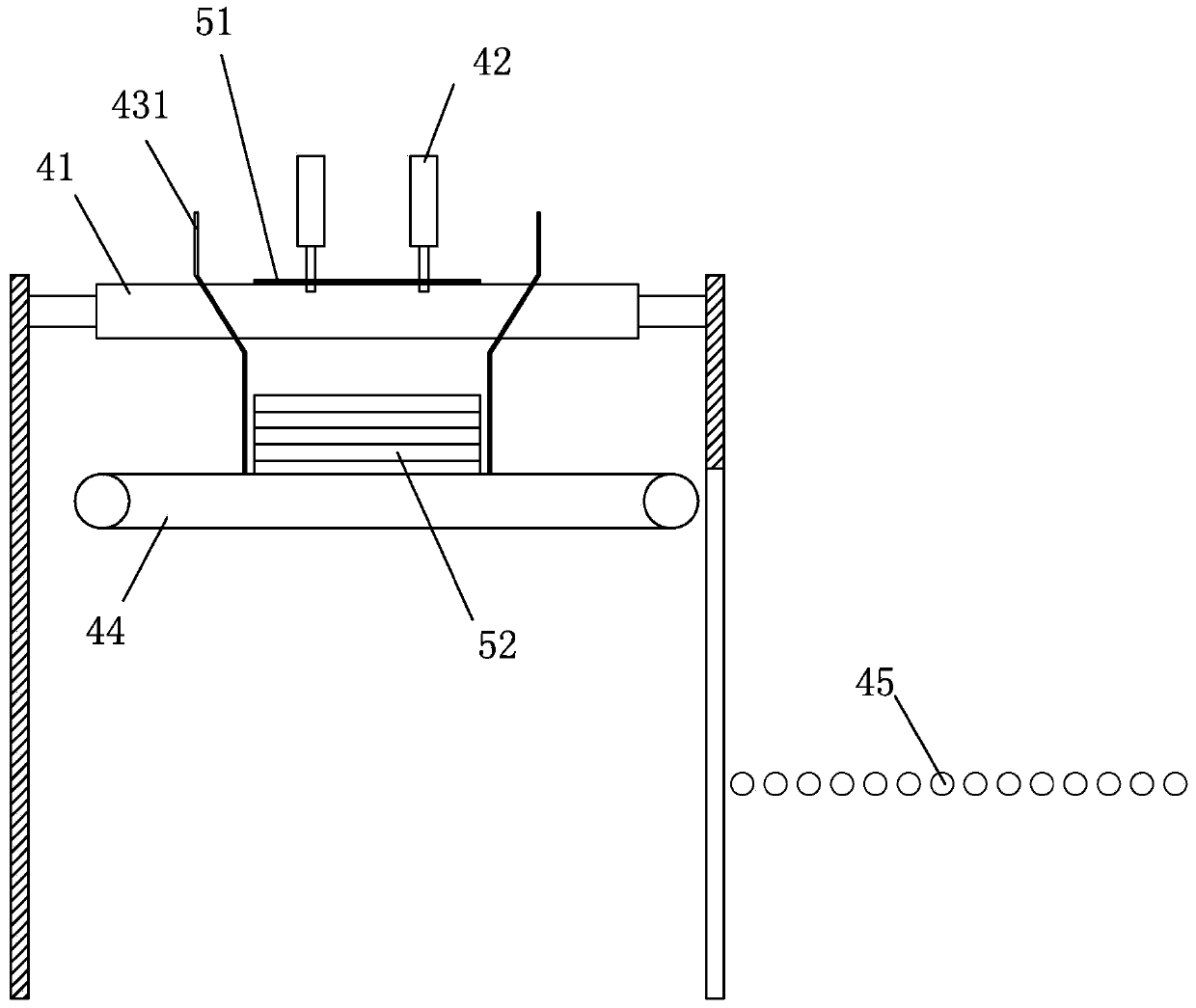

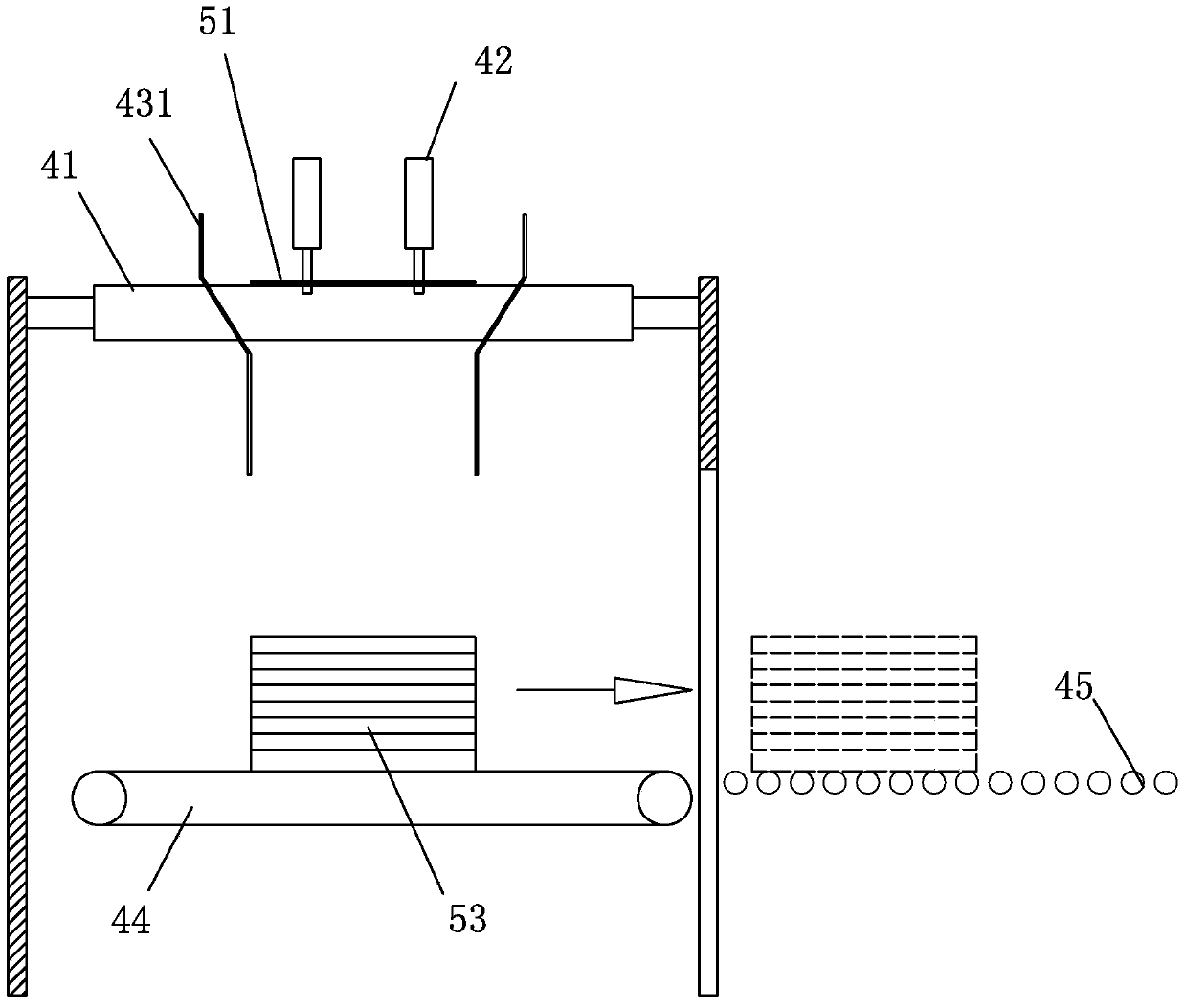

[0033] Such as Figure 4 to Figure 7 As shown, the automatic stacker of the present invention includes a paper delivery mechanism 110, one side of the paper delivery mechanism 110 is provided with a counting sensor 181, and the output end of the paper delivery mechanism is provided with an overturning paper blocking mechanism and a clapping mechanism, A paper supporting mechanism and a paper pushing mechanism are arranged under the snapping mechanism, and a paper storage mechanism is correspondingly arranged on one side of the paper pushing mechanism, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com