Automatic gripping device

A grasping device, automatic technology, used in transportation and packaging, stacking of objects, manipulators, etc., can solve the problems of dumping of wood piles, large size, hurting people's hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

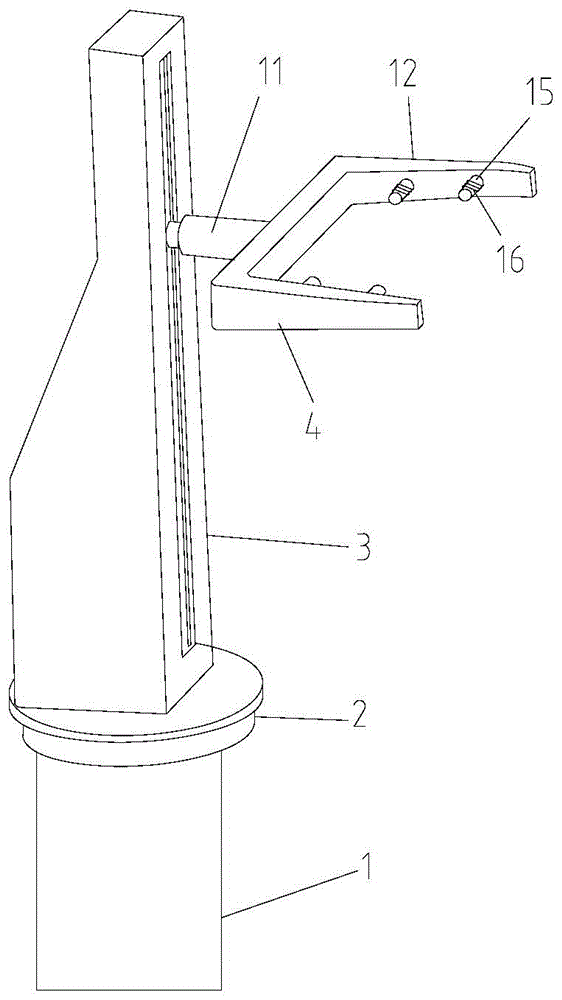

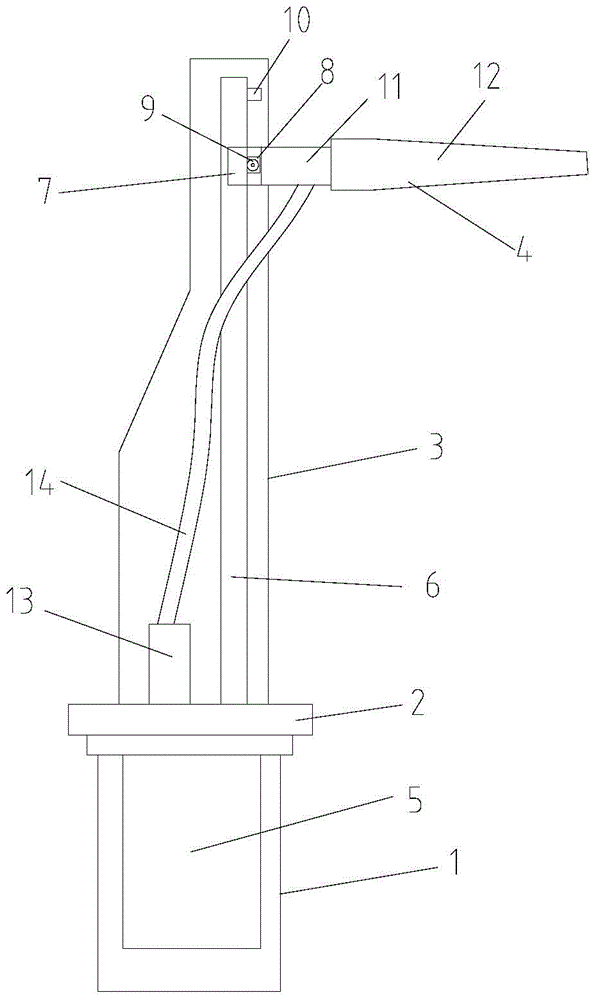

[0012] As shown in the figure, as shown in the figure, an automatic grabbing device includes a base 1, a turntable 2, a mechanical claw mounting frame 3 and a mechanical claw 4, the turntable 2 is arranged on the base 1, and the upper end of the base 1 is connected to the turntable Through the bearing connection, the mechanical claw mounting frame 3 is fixed on the turntable, the mechanical claw mounting frame 3 is arranged on the rotating disk 2, the mechanical claw 4 is connected with the mechanical claw mounting frame 3, and the base 1 is provided with a rotating motor 5, and the rotating motor 5 The output shaft is connected to the turntable 2, and the rotating motor 5 rotates, driving the turntable 2 to rotate, thereby making the mechanical claw mounting frame 3 and the mechanical claw 4 arranged on the rotary table 2 rotate. The mechanical claw mounting frame 3 is provided with a slide rail 6 inside, and the slide rail 6 is provided with a matching sliding sleeve 7, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com