Automatic blanking system for silicon steel sheet stamping production line

A production line, silicon steel sheet technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of manual cutting by workers, inability to apply various specifications, etc., achieve long handling distance, improve equipment utilization, use wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

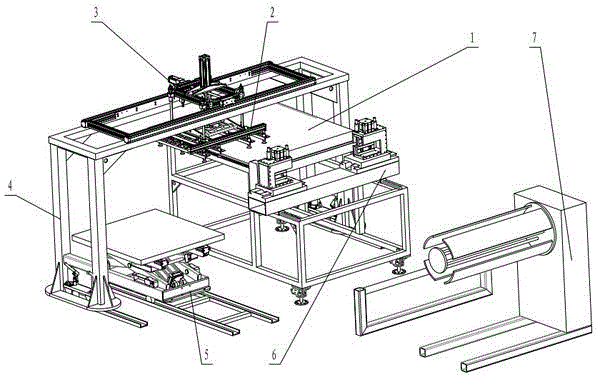

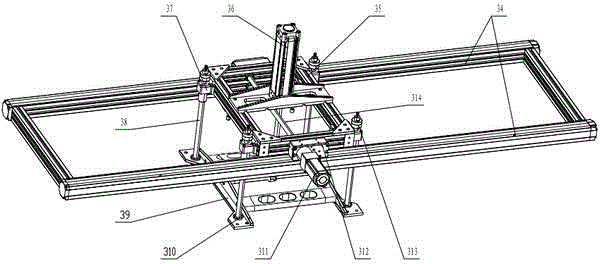

[0073] An automatic blanking system for a silicon steel sheet stamping production line, characterized in that it includes a material receiving system 1, an adsorption system 2, a handling system 3, a support mechanism 4, a palletizing system 5, a waste material cutting system 6 and a waste material rolling system 7;

[0074] The conveying system 3 is connected with the adsorption system 2, the conveying system 3 is installed on the support mechanism 4, and the palletizing system 5 and the material receiving system 1 are arranged below the supporting mechanism 4, and the palletizing system 5 and the receiving system 1 are arranged. The material systems 1 are placed side by side, a waste material cutting system 6 is provided at one end of the material receiving system 1 , and a waste material rolling system 7 is provided beside the waste material cutting system 6 .

[0075] The invention has the advantages of ingenious structural layout, high efficiency, low cost, high speed, hi...

Embodiment 2

[0077] An automatic blanking system for a silicon steel sheet stamping production line, characterized in that it includes a material receiving system 1, an adsorption system 2, a handling system 3, a support mechanism 4, a palletizing system 5, a waste material cutting system 6 and a waste material rolling system 7;

[0078] The conveying system 3 is connected with the adsorption system 2, the conveying system 3 is installed on the support mechanism 4, and the palletizing system 5 and the material receiving system 1 are arranged below the supporting mechanism 4, and the palletizing system 5 and the receiving system 1 are arranged. The material systems 1 are placed side by side, a waste material cutting system 6 is provided at one end of the material receiving system 1 , and a waste material rolling system 7 is provided beside the waste material cutting system 6 .

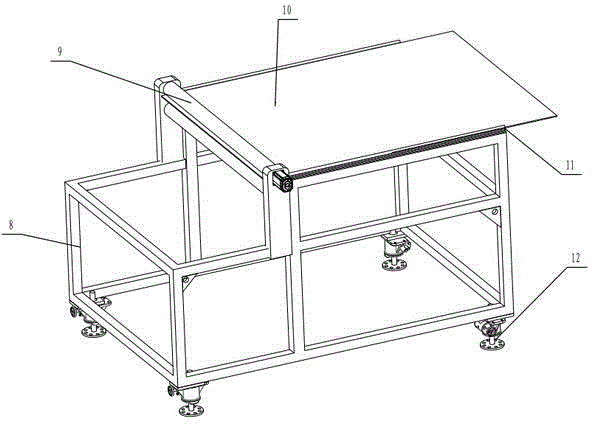

[0079] The material receiving system 1 includes a mounting bracket 8, a height adjusting device 12, a chute 11, a...

Embodiment 3

[0083] An automatic blanking system for a silicon steel sheet stamping production line, characterized in that it includes a material receiving system 1, an adsorption system 2, a handling system 3, a support mechanism 4, a palletizing system 5, a waste material cutting system 6 and a waste material rolling system 7;

[0084] The conveying system 3 is connected with the adsorption system 2, the conveying system 3 is installed on the support mechanism 4, and the palletizing system 5 and the material receiving system 1 are arranged below the supporting mechanism 4, and the palletizing system 5 and the receiving system 1 are arranged. The material systems 1 are placed side by side, a waste material cutting system 6 is provided at one end of the material receiving system 1 , and a waste material rolling system 7 is provided beside the waste material cutting system 6 .

[0085] The invention has the advantages of ingenious structural layout, high efficiency, low cost, high speed, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com