Biomass direct-combustion power generation bottom slag treatment system

A biomass and slag treatment technology, applied in the removal of solid waste, magnetic separation, solid separation, etc., can solve the problems of low utilization rate, waste of space, many impurities, etc., to achieve ingenious structure layout, flexible and convenient operation, system Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The biomass direct combustion power generation bottom slag treatment system of the present invention will be described in detail below in conjunction with the accompanying drawings.

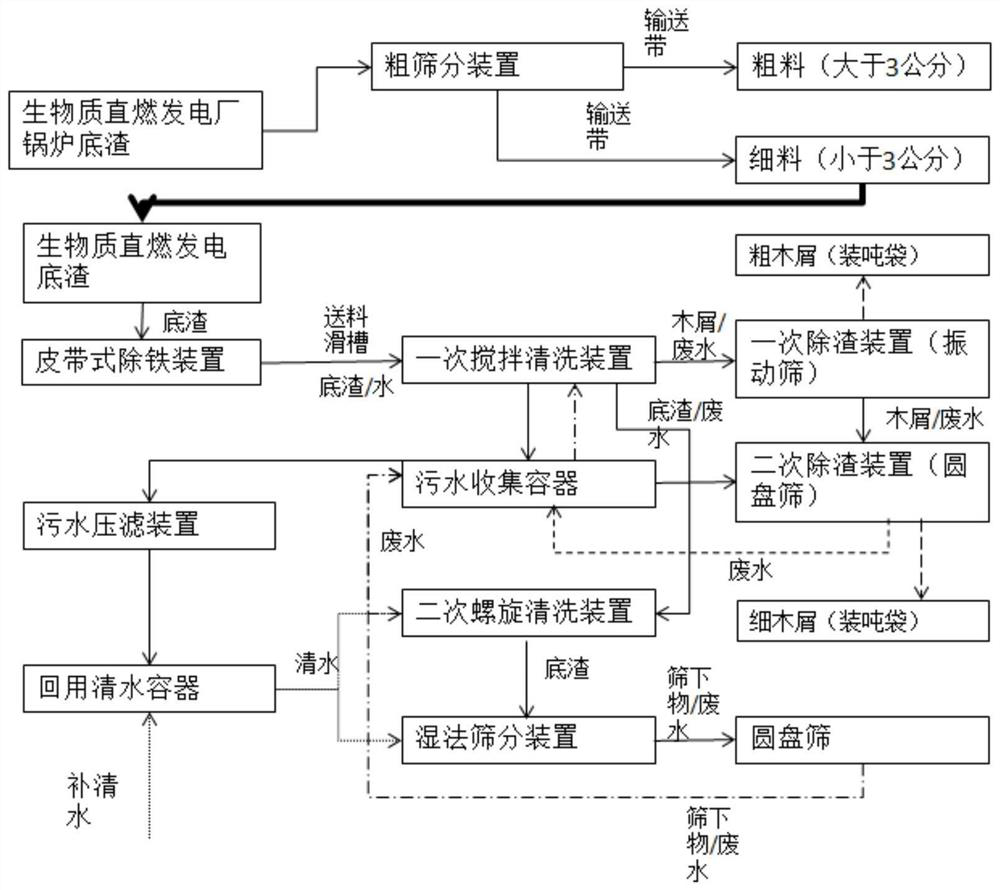

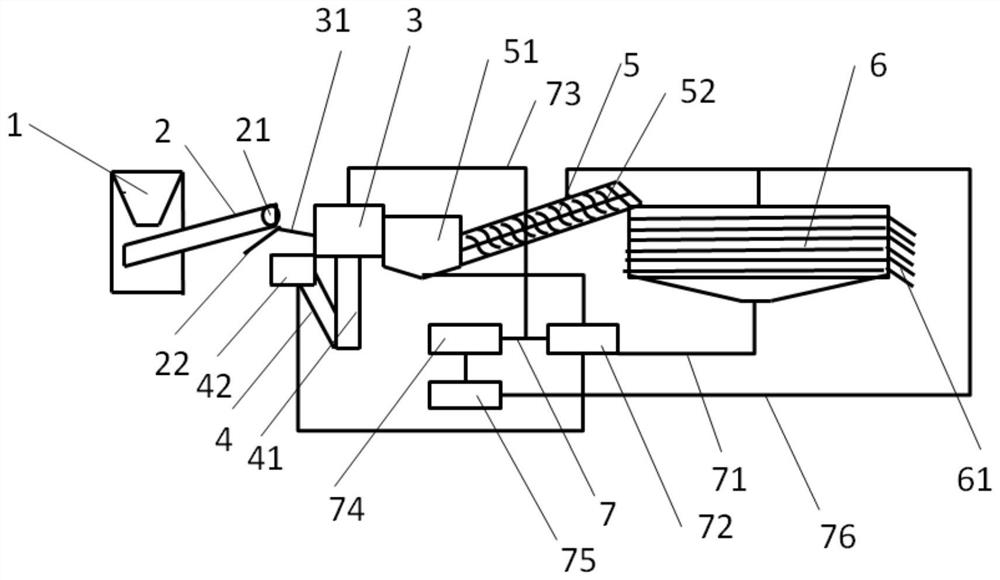

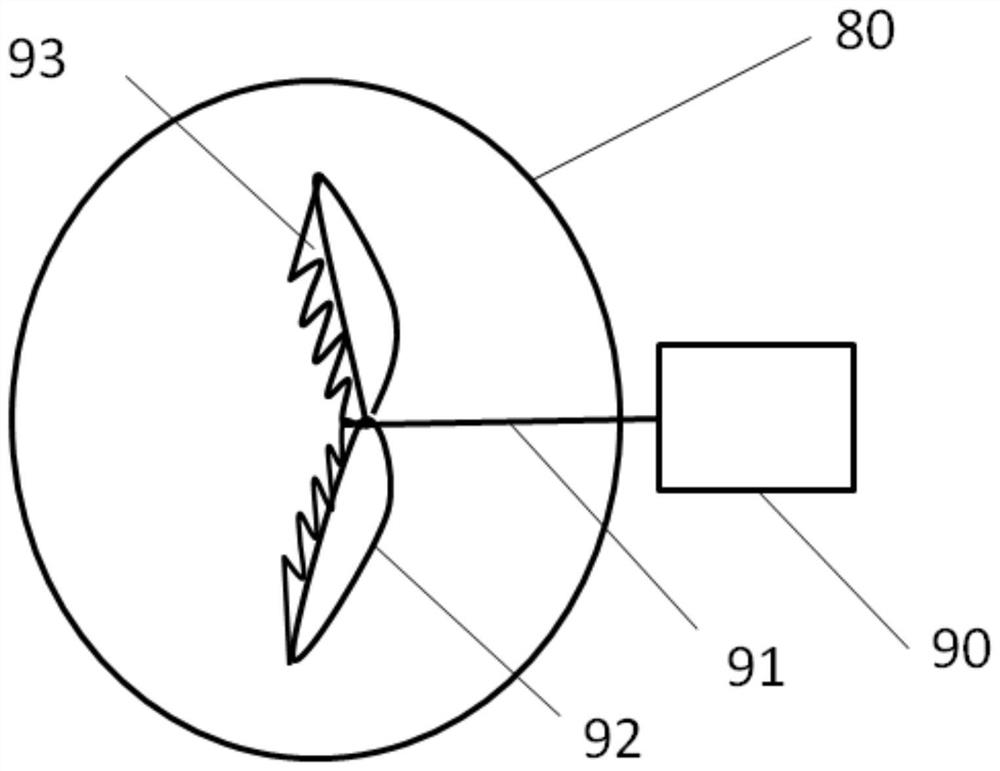

[0020] Such as figure 1 , 2 As shown, a kind of biomass direct combustion power generation bottom slag treatment system of the present invention, a kind of biomass direct combustion power generation bottom slag treatment system, comprises the feeding device 1 connected herewith, the belt type iron removal device 2, a stirring cleaning Device 3, secondary spiral cleaning device 5 and wet screening device 6, the slag removal device 4 used to collect and recycle wood chips is connected to the primary stirring and cleaning device 3, and the water recycling device 7 includes a sewage collection container 72, a pressurized Filtration device 74 and reuse clear water container 75, described sewage collection container 72 is used for collecting described primary agitation cleaning device 3, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com