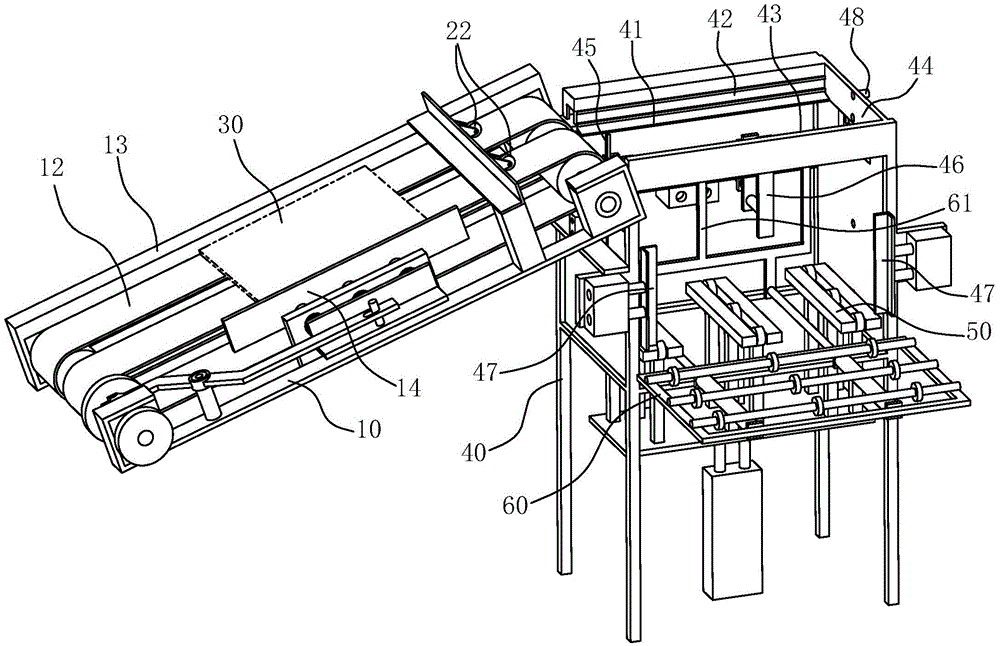

Automatic arranging and stacking device of paper boards

An automatic sorting and cardboard technology, which is used in stacking receiving devices, thin material handling, transportation and packaging, etc., can solve the problems of affecting production efficiency, high production cost of manual operation, and high labor intensity of manual operation, so as to ensure neat stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

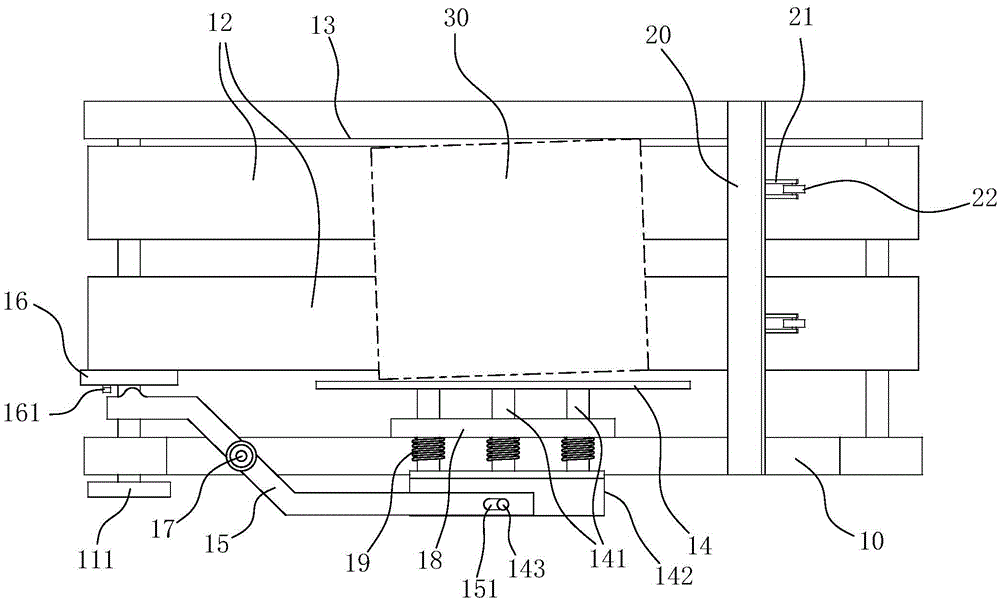

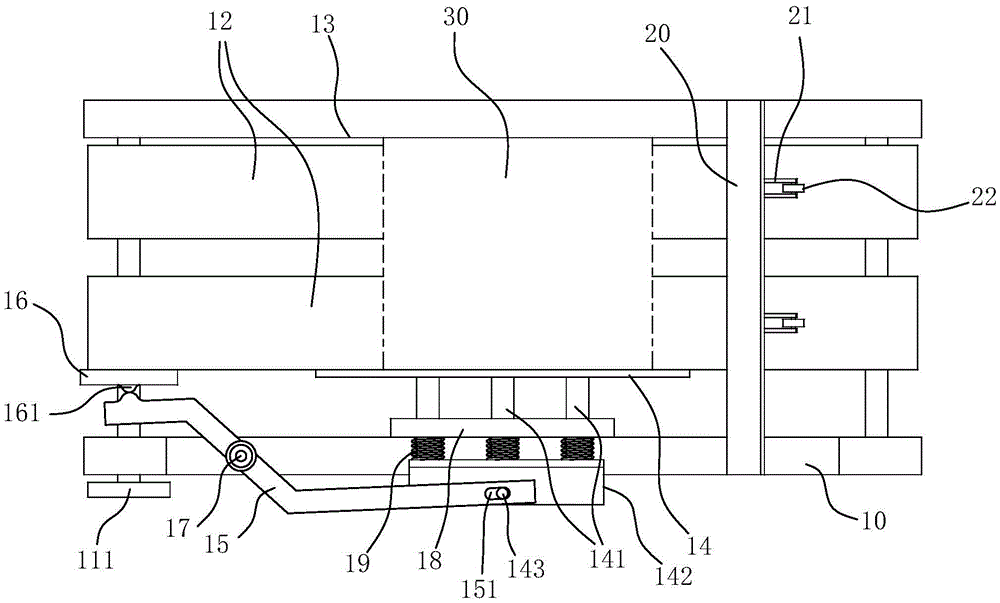

[0021] Such as Figure 1-3 As shown, as a preferred embodiment of the present invention, the frame 10 on the side where the push plate 14 is located is provided with a lever 15, and the lever 15 connects with the frame 10 through a hinge shaft 17 perpendicular to the surface of the conveyor belt 12. Handover; one of the rollers 11a is provided with a cam 16 that rotates synchronously with the roller 11a on the side where the push plate 14 is located, and a smooth transition convex portion 161 is provided on the outer end surface of the cam 16, and one end of the lever 15 The other end of the lever 15 is connected to the push plate 14 to drive the push plate 14 to move closer to the direction of the blocking wall 13 .

[0022] Further, an elastic reset unit for driving the push plate 14 away from the blocking wall 13 is also provided on the frame 10 on the side where the push plate 14 is located.

[0023] Further, at least two guide posts 141 are provided on the outside of the...

Embodiment 2

[0028] Except above-mentioned embodiment 1, this device can also adopt cylinder to drive push plate 14 to realize reciprocating motion, when adopting cylinder to drive, can arrange a position sensor at the corresponding position of cylinder, when position sensor detects that cardboard 30 passes by, control The system automatically controls the movement of the cylinder. The advantage of this embodiment is that the structure is simple and easy to implement, and the disadvantage is that the manufacturing and use costs are relatively high.

[0029] In addition, in order to ensure that the cardboard 30 is fed smoothly on the conveyor belt, a beam 20 is provided above the conveyor belt 12 downstream of the push plate 14, and a roller bracket 21 is provided on the beam 20, and rollers are provided on the roller bracket 21. 22. The axes of the rollers 22 are parallel to the rollers 11a and 11b, and the wheel surface of the rollers 22 is in close contact with the belt surface of the co...

specific Embodiment

[0030] The specific embodiment of finishing mechanism of the present invention is as follows:

[0031] Such as Figure 4-7 As shown, one end of the two pallets 41 is provided with a second blocking wall 44, and the other end is provided with a first push plate 45 parallel and opposite to the second blocking wall 44, and the first push plate 45 is opposite to the second blocking wall. The wall 44 moves closer or farther away.

[0032] Further, the outer side of the edge corresponding to the first retaining wall 43 of the first bracket 50 is provided with a baffle plate 47 , and the outer side of the edge corresponding to the splint 42 of the first bracket 50 is provided with a baffle plate 47 The parallel second push plate 46 moves closer or farther away from the baffle plate 47 .

[0033] Preferably, both the second blocking wall 44 and the first push plate 45 extend downward to the corresponding heights of the second push plate 46 and the baffle plate 47 .

[0034]Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com