Full-automatic drum-type precision seeding flow line

A precision seeding, drum-type technology, applied in the field of agricultural machinery, can solve the problems of affecting seed cultivation, high labor intensity, uneven material blanking, etc., and achieve the effects of simple structure, energy saving and production efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

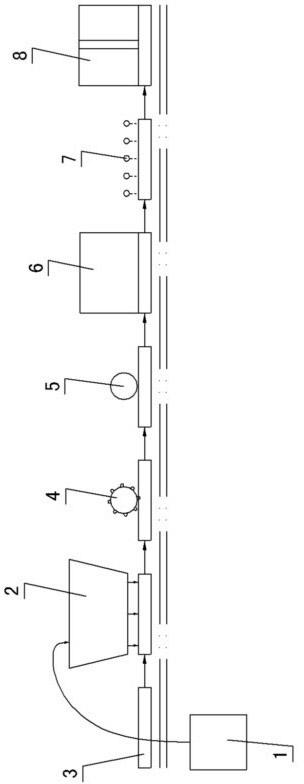

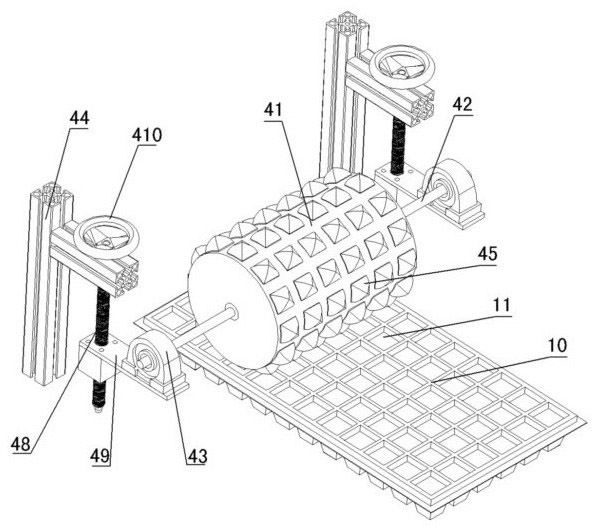

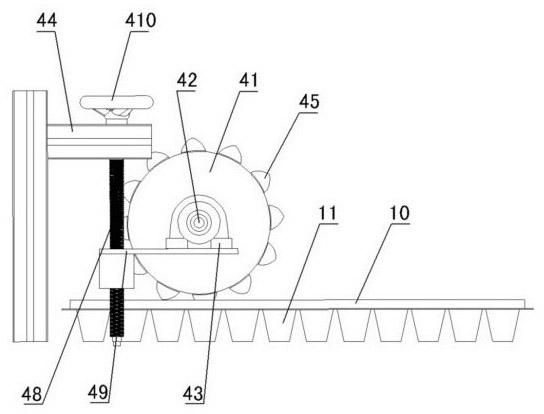

[0020] The invention relates to a fully automatic drum type precision seeding assembly line, such as Figure 1-Figure 13Shown, comprise soil material mixing mechanism 1, soil loading device 2 and the seedling raising tray 10 that is installed on the frame 9 and enter the tray mechanism 3, pressure hole device 4, sowing mechanism 5, covering soil device 6, sprinkling device 7 and disc stack Put mechanism 8, the concrete technical scheme of described soil mixing mechanism 1, upper soil device 2, seedling raising tray 10 into tray mechanism 3 and sprinkler 7 is by many kinds, also has sale on the market, belongs to prior art. It is characterized in that the described cavitation device 4 includes a cavitation wheel 41, a cavitation rotating shaft 42 is installed in the cavitation wheel 41, the two ends of the cavitation rotating shaft 42 are connected with a cavitation bearing seat 43, and the cavitation bearing seat 43 Be installed on the seeder frame 44, be shaped on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com